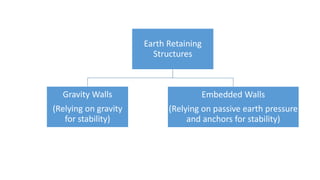

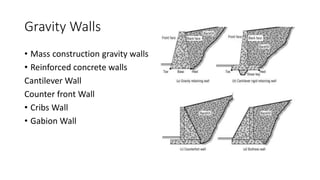

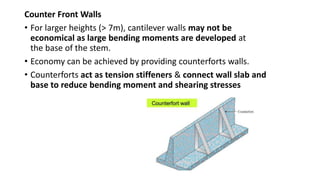

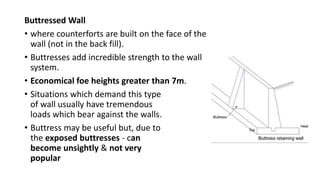

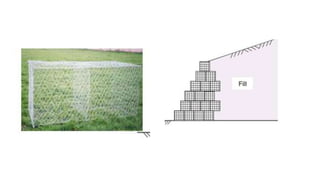

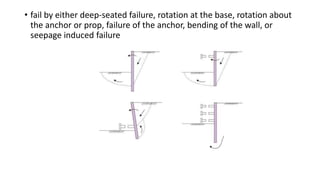

Earth retaining structures are used to support soil and structures where there are differences in ground elevation. There are two main types: gravity walls, which rely on their own weight for stability, and embedded walls, which rely on passive earth pressure and anchors. Gravity walls include mass concrete walls, reinforced concrete cantilever walls, counterfort walls, crib walls, and gabion walls. Cantilever walls are the most common reinforced concrete wall for heights up to 7 meters. Counterfort walls provide greater stability for taller walls over 7 meters. Embedded walls include sheet pile walls made of steel, timber, or concrete, and diaphragm walls which are reinforced concrete walls installed like sheet pile walls.