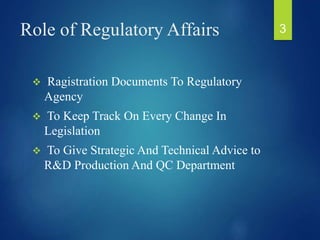

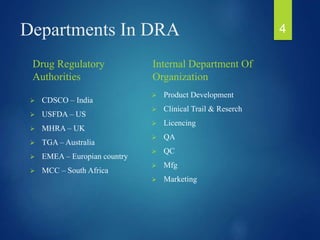

Regulatory affairs is a profession that developed to ensure public health by regulating product safety. Regulatory affairs professionals work with regulatory agencies and internal departments to register products, track legislation changes, and provide strategic advice. They must understand both internal manufacturing processes and requirements from agencies like CDSCO in India or the USFDA.

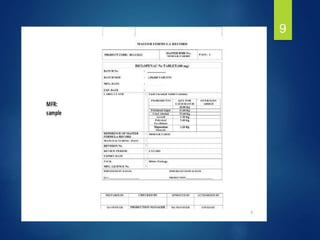

A Master Formula Record (MFR) is a key document that contains all information about manufacturing a pharmaceutical product, including starting materials, packaging, and processing instructions. It is prepared by R&D as the standard reference for making Batch Manufacturing Records. The MFR must include product details, a procedure description, and all ingredients and their quantities. It ensures consistent manufacturing of batches according to the standard process.