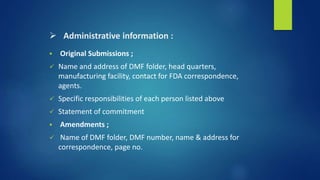

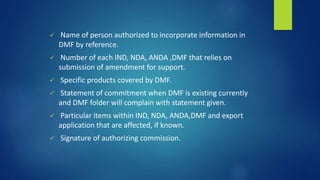

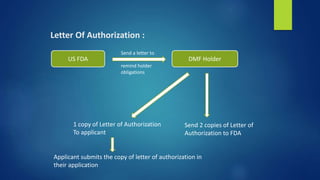

This document discusses regulatory affairs documentation including Master Formula Records (MFRs) and Drug Master Files (DMFs). It explains that MFRs provide complete product descriptions to ensure batch-to-batch uniformity, while DMFs confidentially provide manufacturing and quality control information to regulatory agencies. Key elements of these documents are outlined, such as their structure, components, procedures for preparation and maintenance, and importance in obtaining marketing authorization and maintaining compliance.

![REGULATORY AFFAIRS

Prepared by;

Kusuma Latha Beera,

M.Pharmacy ,1st sem

GITAM Institute Of Pharmacy,

GITAM [ Deemed to be university ]

Master Formula Record (MFR)

Drug Master File (DMF)](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/75/Regulatory-affairs-1-2048.jpg)

![ Role of Master Formula Record [MFR] according to the

guidelines from different countries;

• European Guidelines : MFR is not only for every batch

but it includes manufacturing formula and

instructions to be maintained for each product that to

be manufactured in one document.

• Canadian Guidelines : MFR is set of documents

specifying the raw materials with quantities and

packaging materials with detailed descriptions of

manufacturing procedures and precautions required

to produce the specified quantity.](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/85/Regulatory-affairs-11-320.jpg)

![Procedure :

A Master Formula Record is either prepared based upon

experience of competent qualified staff [ Analytical Chemist /

Manufacturing Chemist ] or prepared based upon on the

manufacturing record of a batch size.

Master Formula Record cannot be ignored. Once it is prepared

it is transferred to previous staff to new staff.

It is followed as a standard document for processing a batch](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/85/Regulatory-affairs-18-320.jpg)

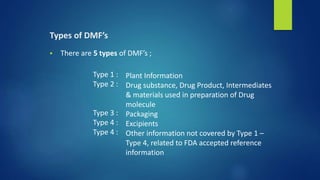

![Drug Master File :

It is a document prepared by Pharmaceutical Manufacturer and

submitted solely at its discretion to appropriate regulatory

authority in the intended drug market. [ followed by submission

of information to FDA ]

It provides the regulatory authority with ;

Confidential detailed information [ Chemistry, Manufacturing &

Control

Process or articles used in manufacturing

Complete information of API or Finished dosage form](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/85/Regulatory-affairs-21-320.jpg)

![ Transmittal Letter :

Original submissions and amendments ;

Identification of submission [ original / supportive to original

DMF

Type of DMF & Subject [ update, revised formula or revised

process ]

Name & address of each sponsor, applicant / holder & all

document numbers

Signature of holder

Type written name & title of signer](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/85/Regulatory-affairs-30-320.jpg)

![Applicable laws :

Food Drug and Cosmetic Act [ FD & C Act ]

Food Drug and Administration Safety Information Act [

FDASIA ]

The Generic Drug User Fee Act [ GDUFA ]

Prescription Drug User Fee Act [ PDUFA ]

Applicable Regulation :

314 New Drug Application [NDA] and

Abbreviated NDA [ANDA]

• 314.50 Content and Format of an application

• 314.70 Changes to an Approved Application

• 314.420 Drug Master Files](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/85/Regulatory-affairs-35-320.jpg)

![ If there is no updation, then NDA, INDA, ANDA process will slow

down.

Any transfer of NDA / ANDA, the aim of transferring should be

mentioned as.,

• The name of the transfer

• Address of the transfer

• Name of responsible official for transferring

• Effective date of transferring

• Signature of the transferring official

• Title of the person

• Letter of acceptance [ Information given should be updated

after acceptance]](https://image.slidesharecdn.com/regulatoryaffairs-181118095428/85/Regulatory-affairs-39-320.jpg)