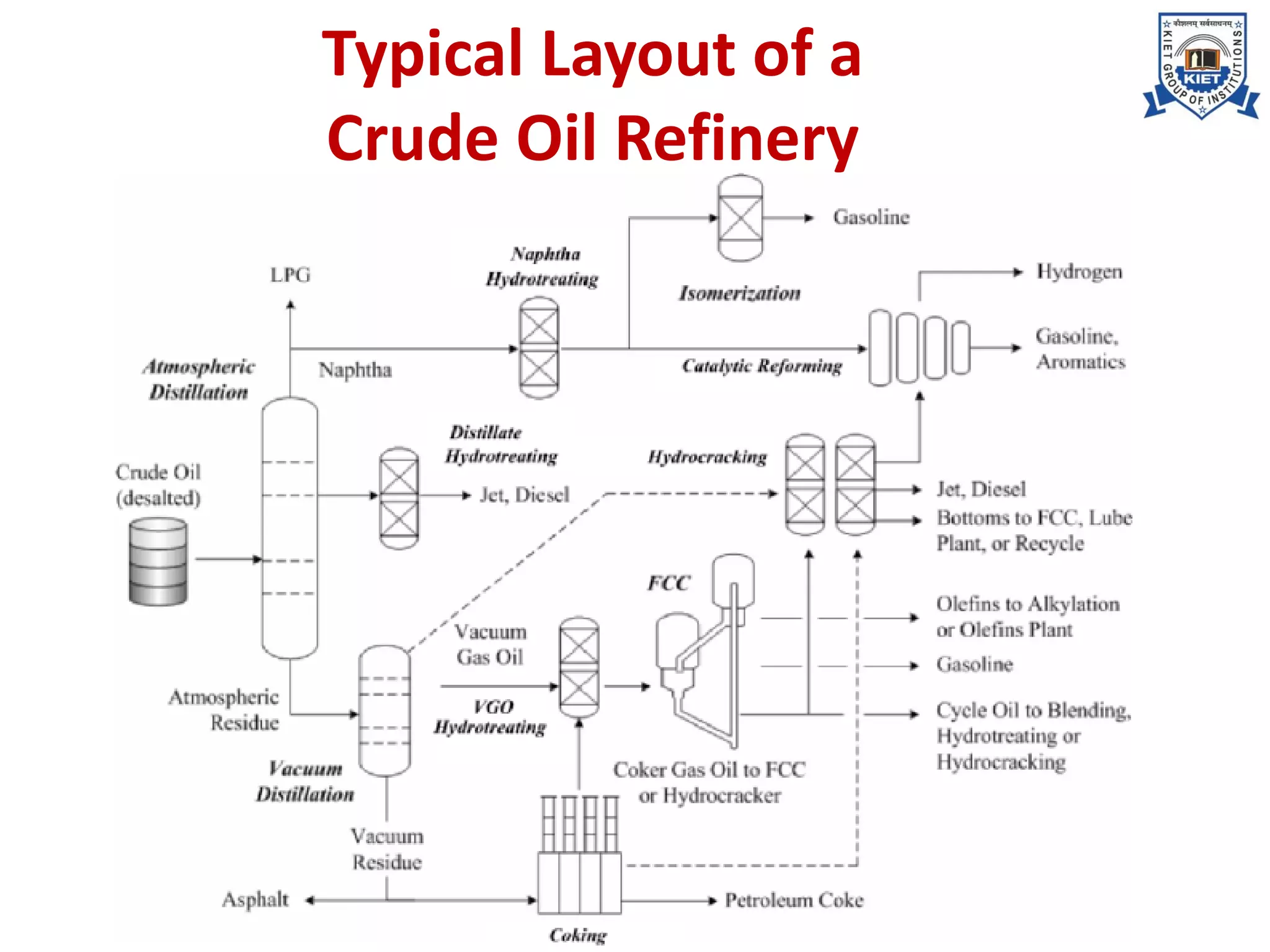

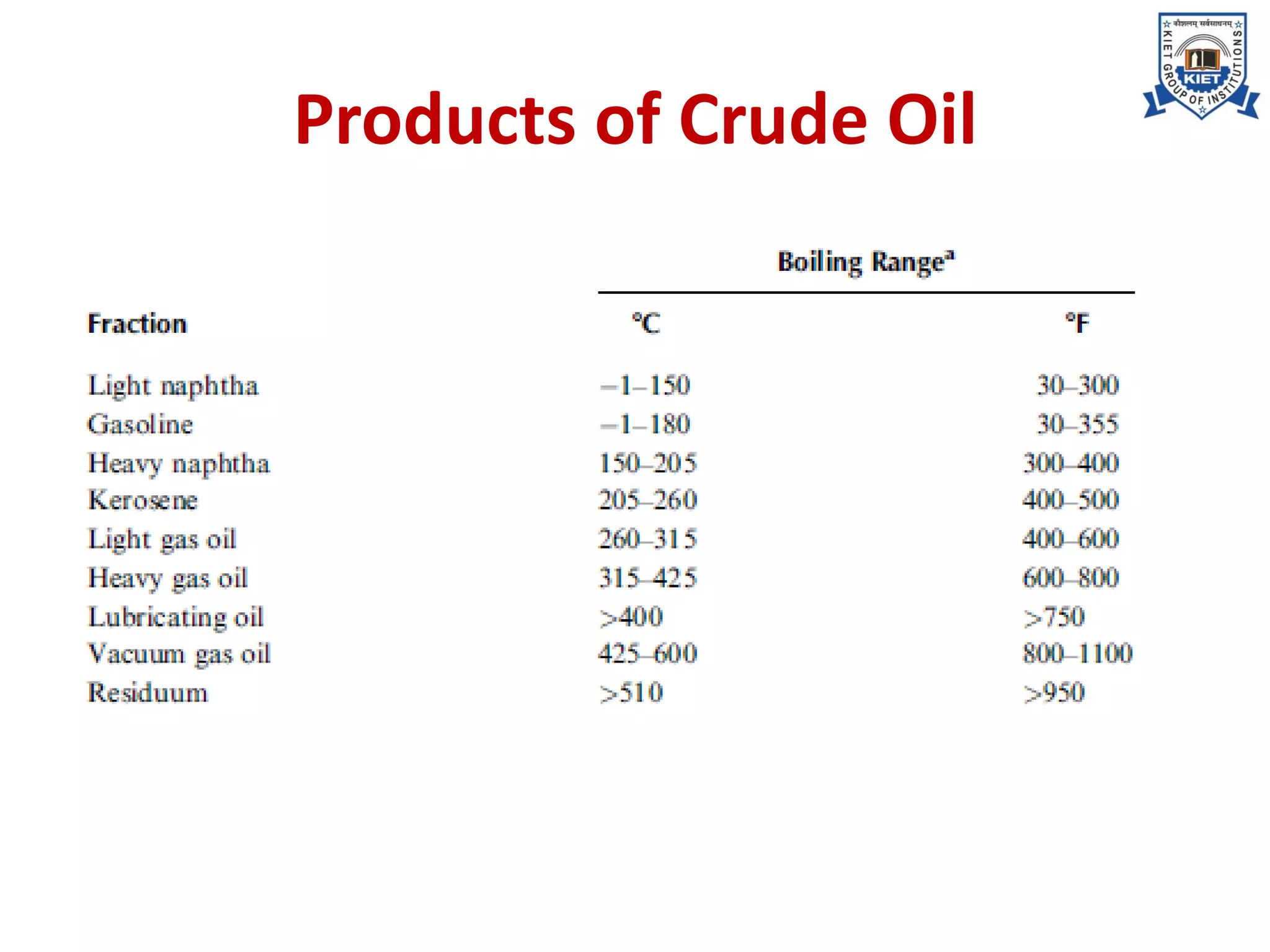

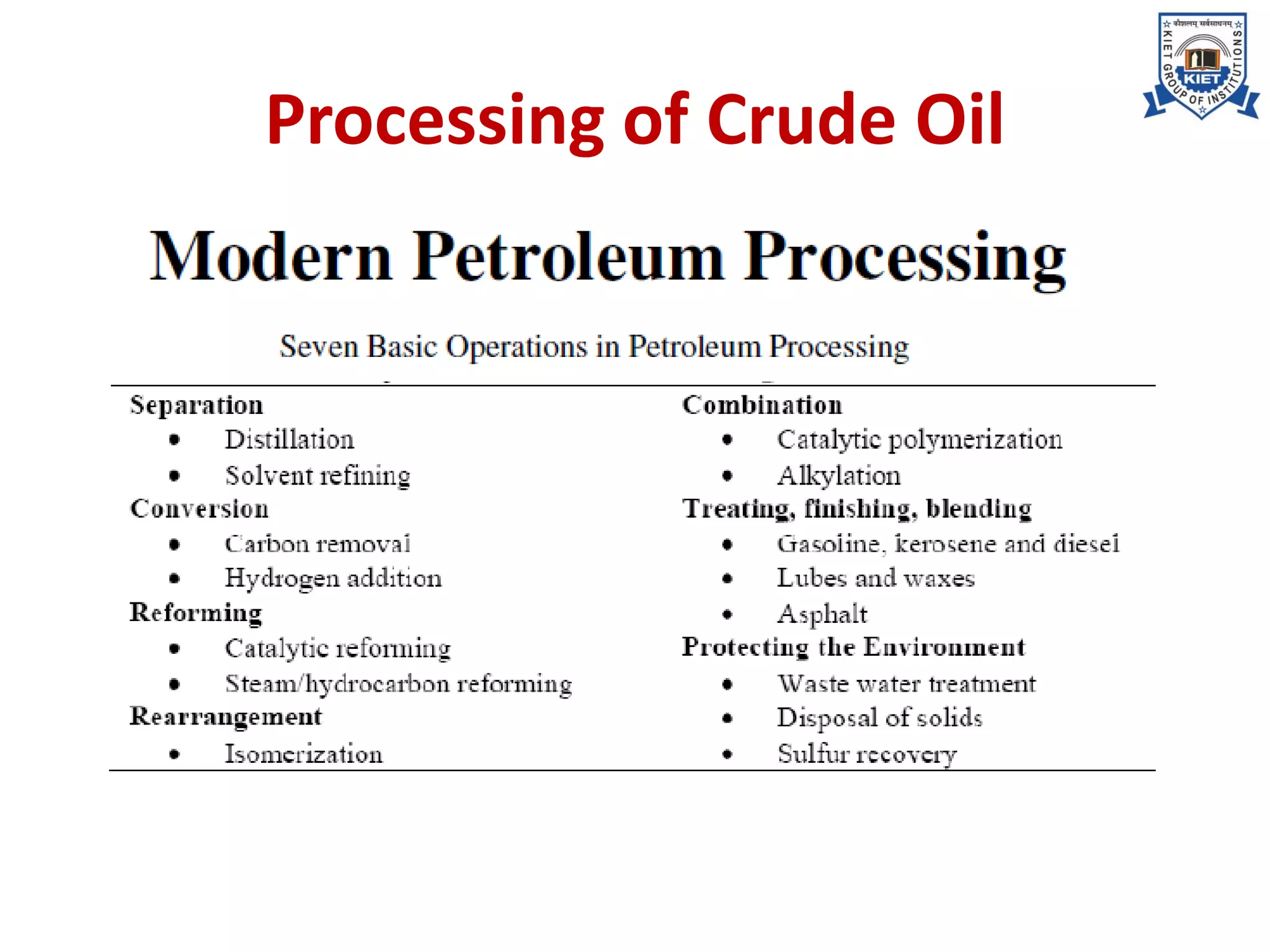

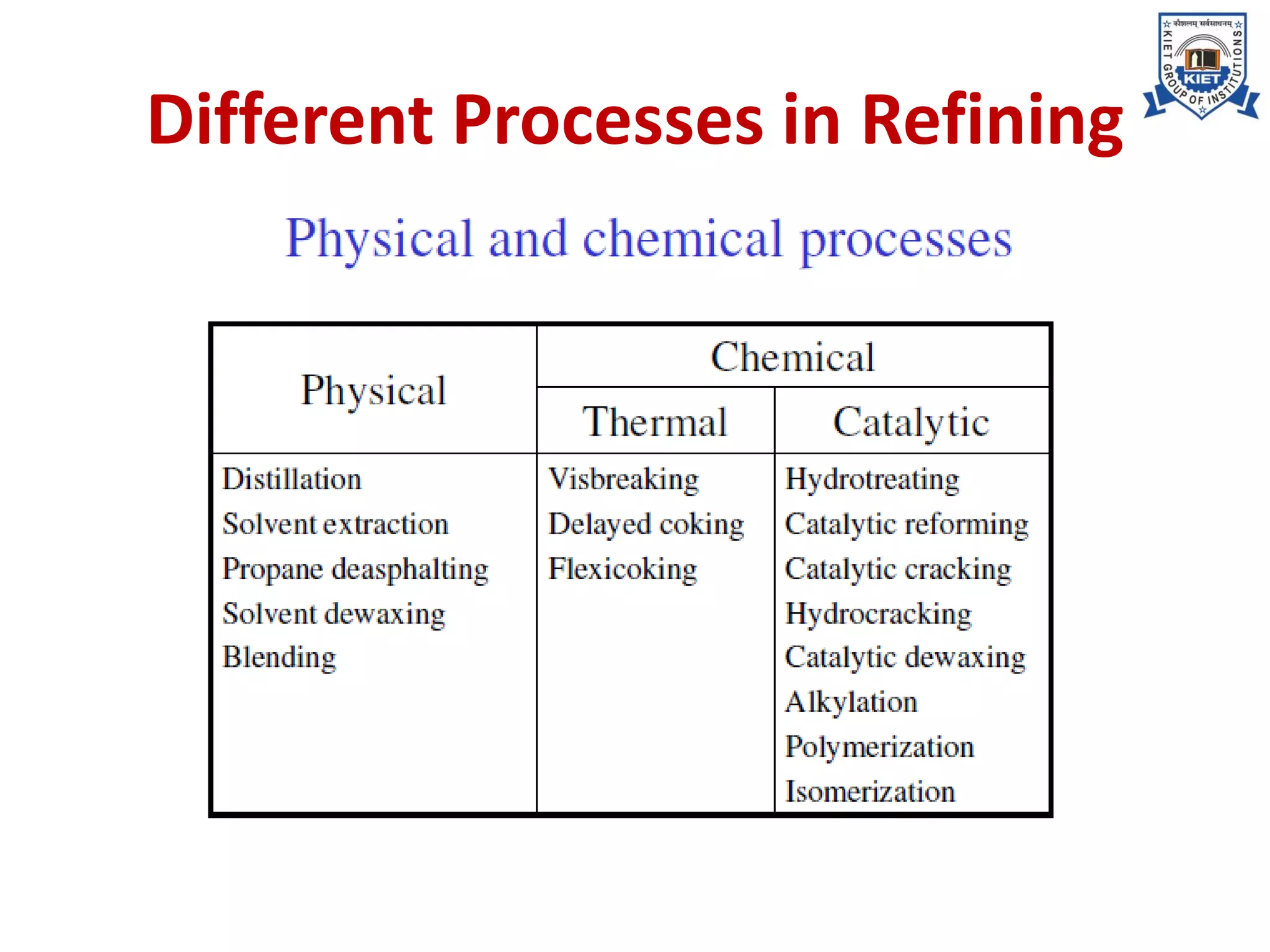

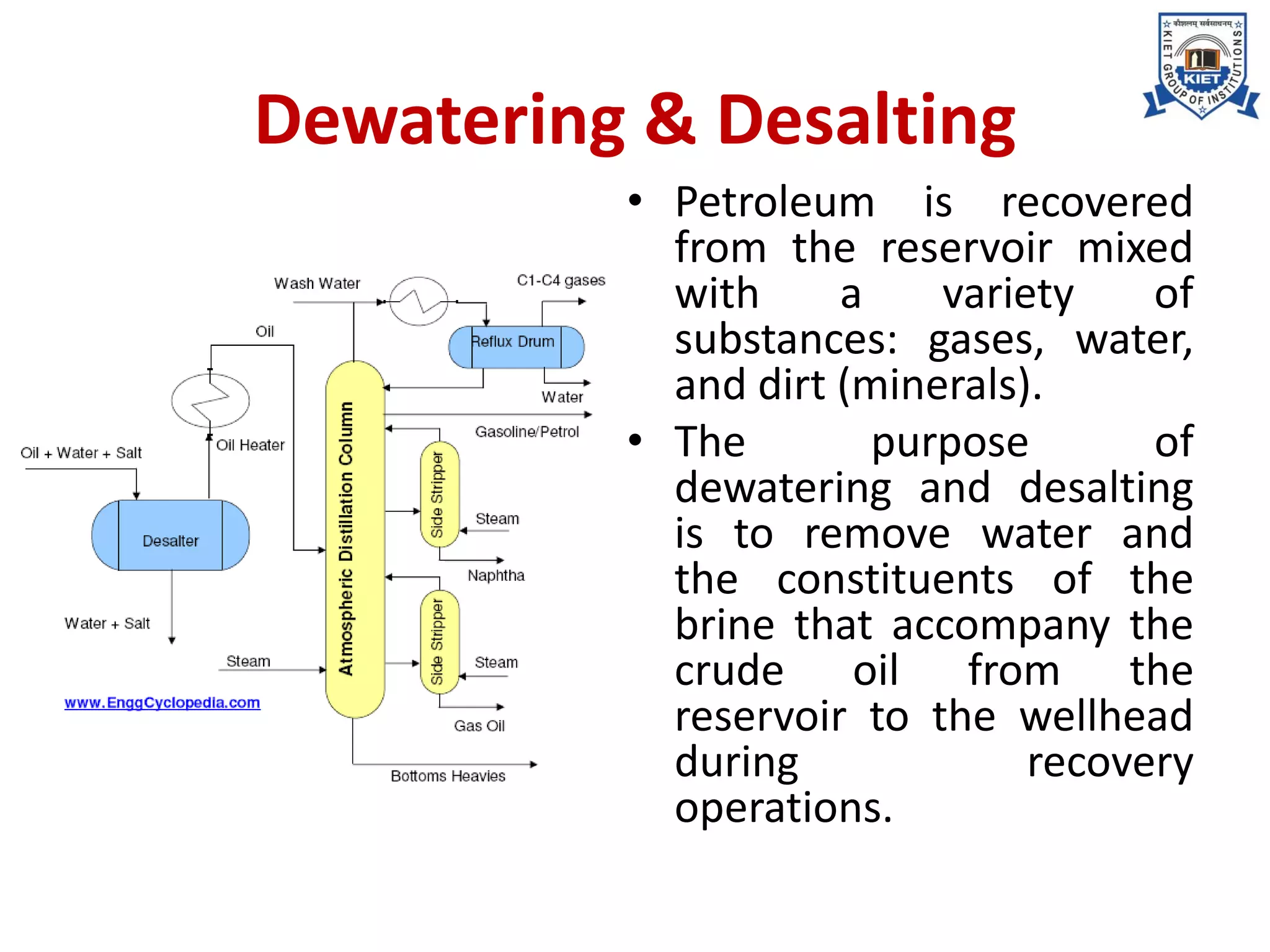

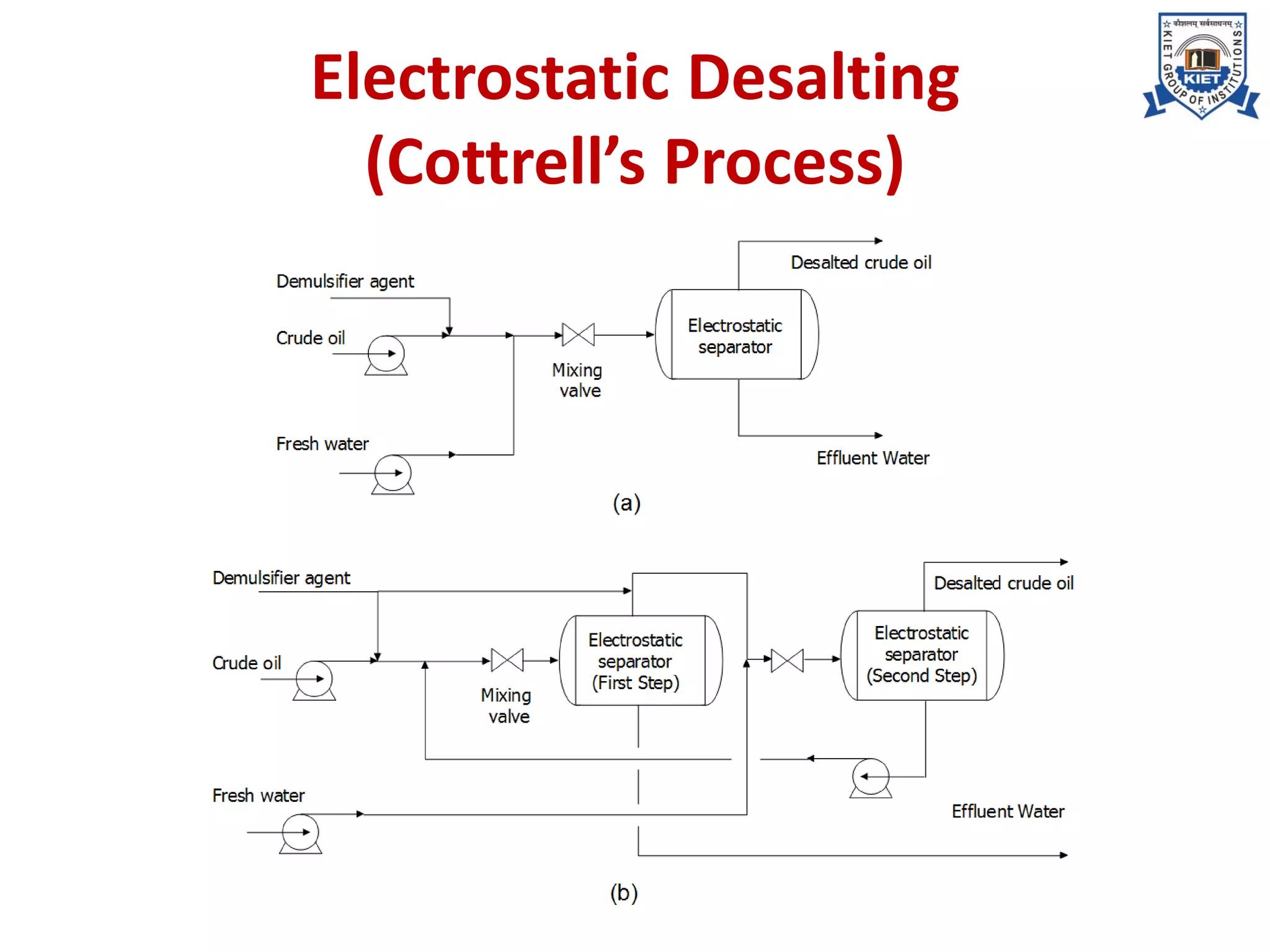

The document outlines the processing of crude oil, detailing key operations such as fractionation, conversion, treatment, and blending of hydrocarbon products. It describes the initial pretreatment of crude oil, emphasizing dewatering and desalting processes that remove contaminants to prevent operational issues in refining. Additionally, it highlights various refining operations and the importance of maintaining compliance with transport regulations regarding water and salt content.