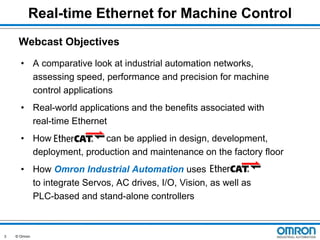

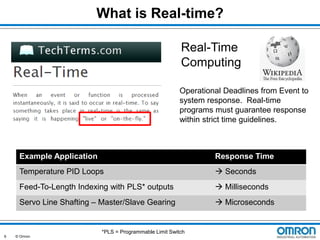

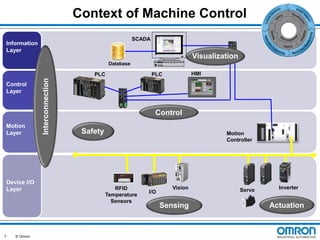

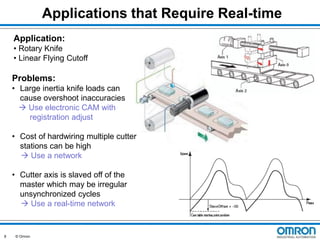

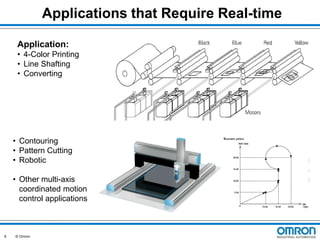

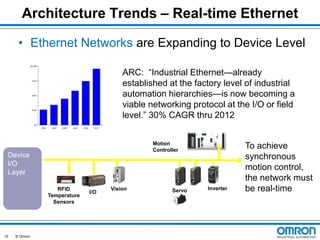

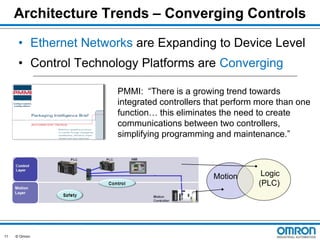

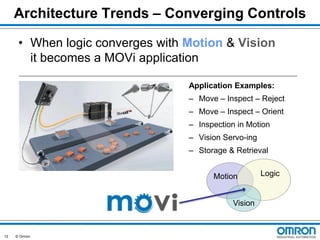

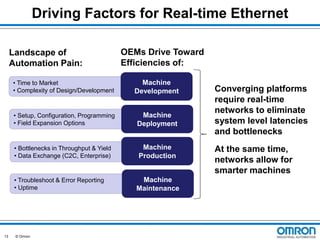

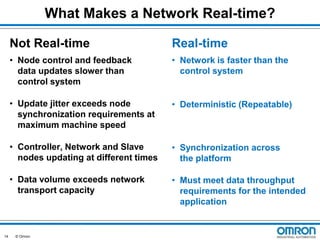

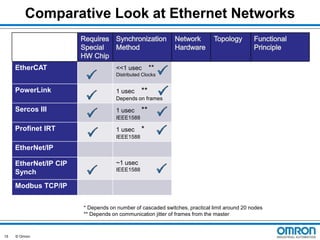

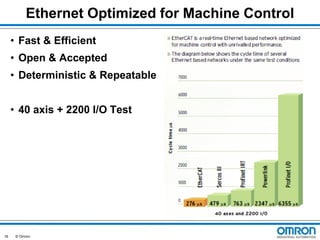

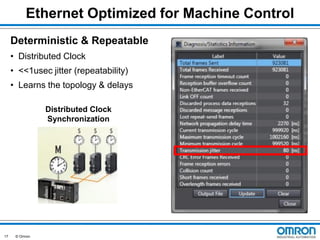

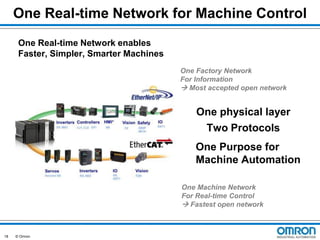

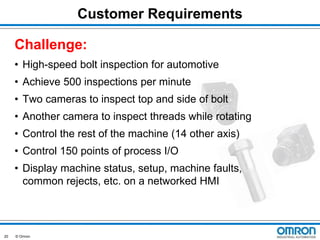

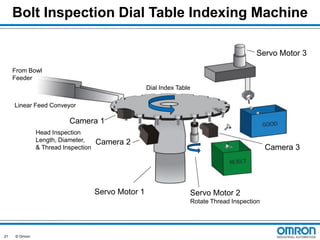

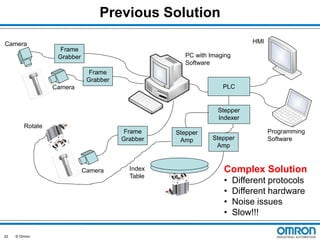

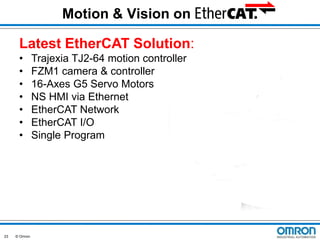

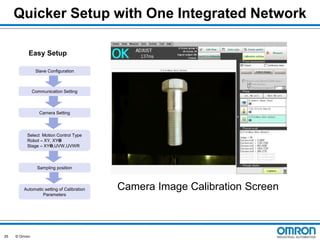

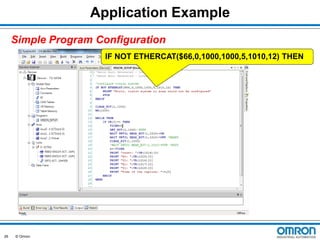

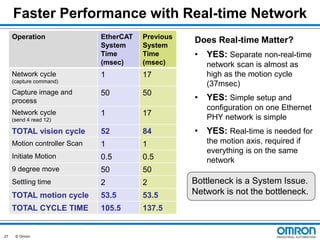

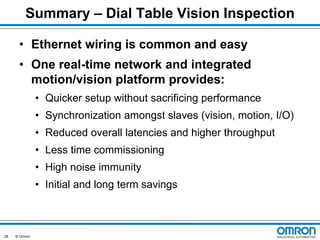

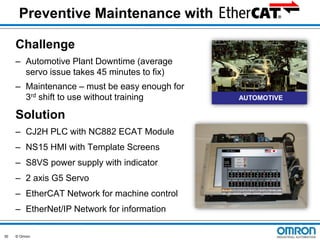

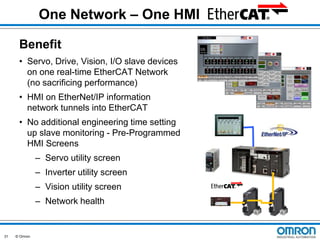

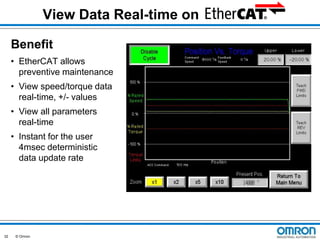

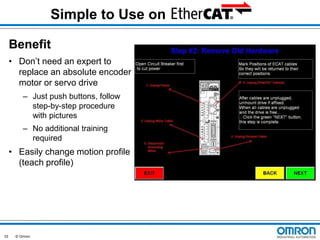

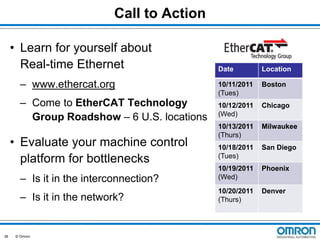

The webcast discusses real-time Ethernet for machine control, highlighting its benefits such as increased speed, precision, and integration with industrial automation systems. Key topics include the architecture trends, application examples, and the importance of real-time networks in optimizing machine performance and maintenance. The presentation emphasizes the need for machine builders to adopt real-time networking solutions to enhance efficiency and reduce complexities in manufacturing environments.