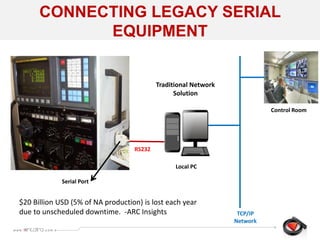

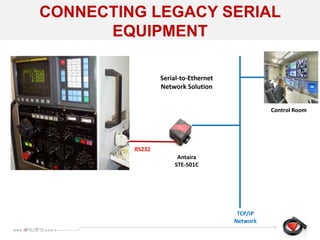

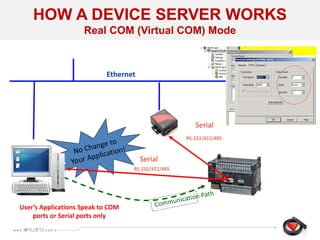

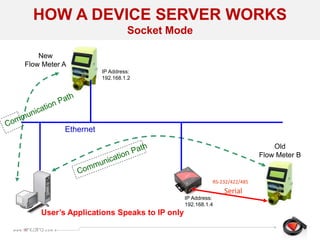

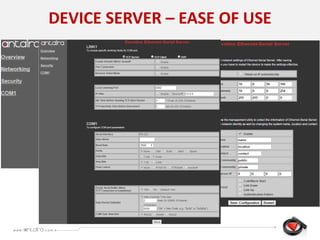

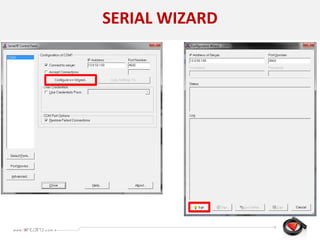

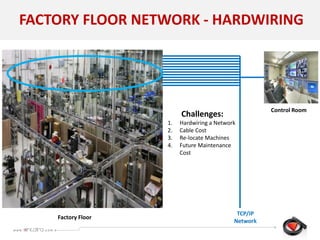

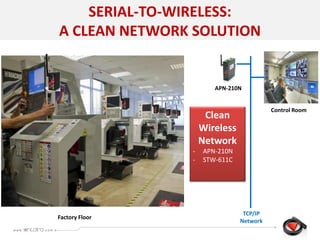

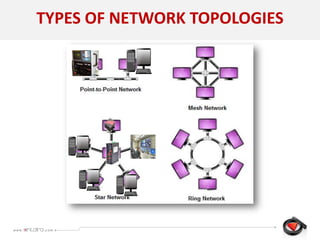

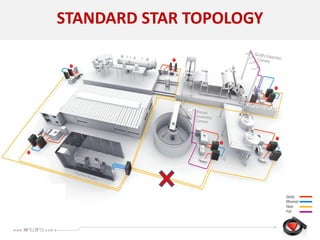

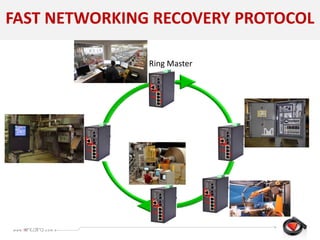

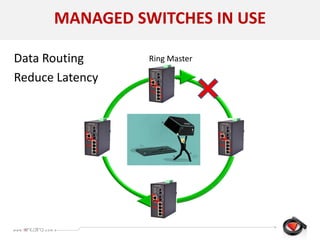

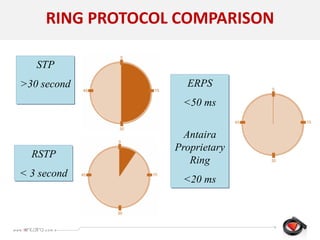

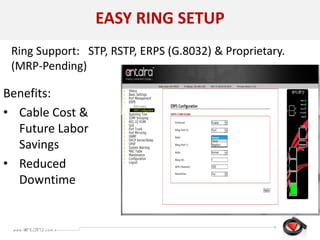

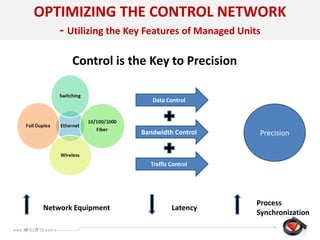

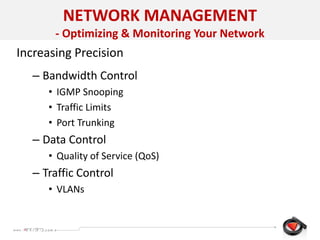

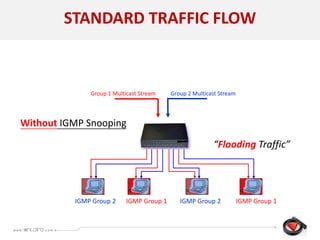

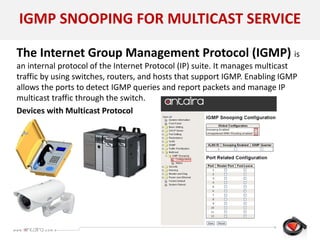

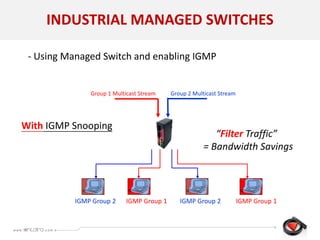

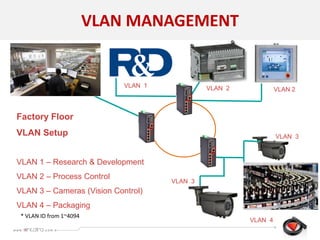

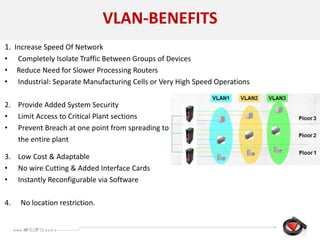

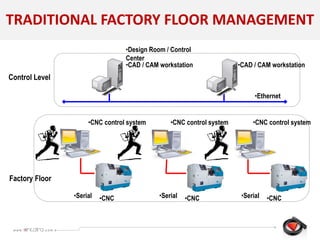

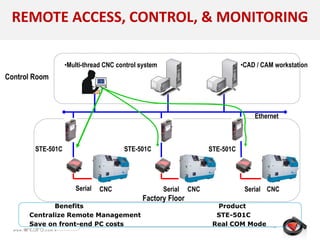

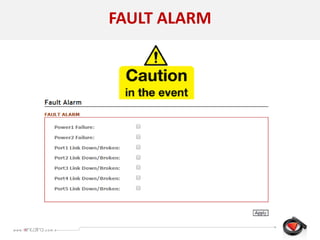

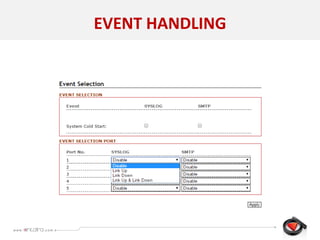

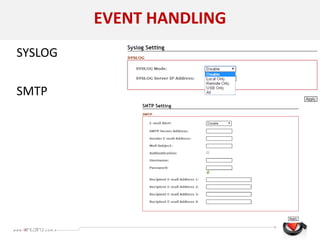

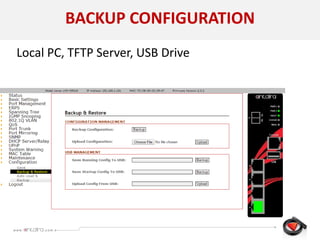

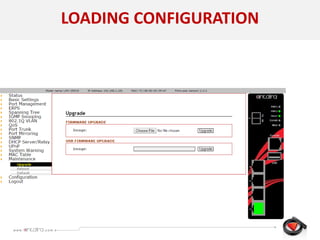

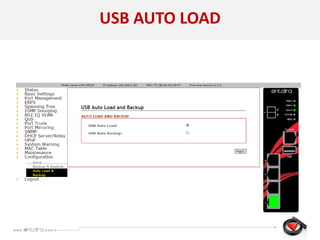

The document discusses how managed switches can enhance industrial networking and automation. It covers connecting legacy serial devices to an Ethernet network using device servers, upgrading to an industrial Ethernet or wireless infrastructure using ruggedized switches, and how self-healing redundant networks can reduce downtime. It also discusses how managed switches can improve process control precision with features like QoS, VLANs, and IGMP snooping. Finally, it covers additional features of managed switches like remote access, event handling, configuration backup and restore, and USB auto loading.