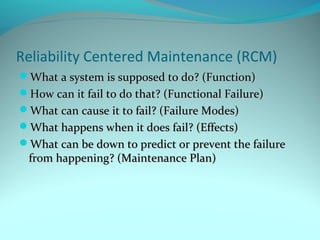

Reliability Centered Maintenance (RCM) is a logical approach developed in the 1960s that helps companies improve equipment reliability by determining potential failure modes and maintenance plans. RCM analyzes a system's functions, potential failures, and failure effects to develop a maintenance plan. Implementing RCM increases maintenance effectiveness by ensuring the right type and frequency of maintenance, and increases efficiency by comparing maintenance costs to equipment downtime costs. RCM also provides benefits like upskilling maintenance technicians and operators through cross-training on equipment operation and failure analysis.