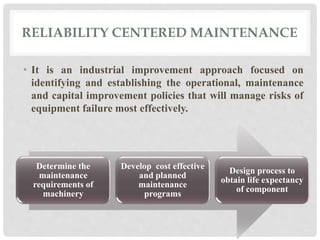

This document discusses reliability centered maintenance (RCM) and its implementation at Boeing. It provides background on Boeing and describes RCM's focus on identifying maintenance policies to manage equipment failure risks. The document outlines how Boeing initially used RCM in 1969 but then discusses reasons for failures in Boeing's 787 fleet, such as over-reliance on outsourcing. It concludes by suggesting improvements like monitored outsourcing, focusing on condition monitoring and predictive maintenance using RCM.