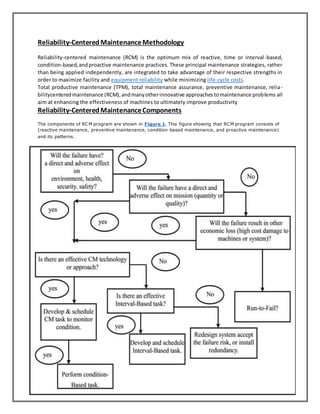

This document discusses reliability-centered maintenance (RCM). It defines RCM as a corporate maintenance strategy that aims to optimize maintenance programs by preserving system functions through identifying failure modes and selecting effective tasks to control failures. The document outlines the history and principles of RCM, describing the classical and streamlined approaches. It provides an overview of the basic RCM process, which involves preparation, analysis, task selection, comparison, and record keeping. The advantages of RCM include lowering costs and minimizing failures, while disadvantages include startup costs and challenges dealing with hidden failures.