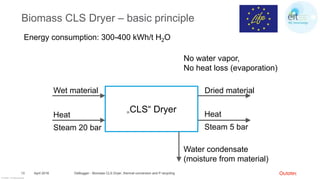

The document presents the Outotec debugger project focused on biomass drying, thermal conversion, and nutrient recycling, highlighting the technological advancements for efficient resource recovery. It outlines the need for nutrient management to address environmental issues like eutrophication and showcases the energy-efficient closed-loop steam drying process. The results of gasification tests indicate that sewage sludge and manure can be effectively processed to yield syngas comparable to wood pellets.