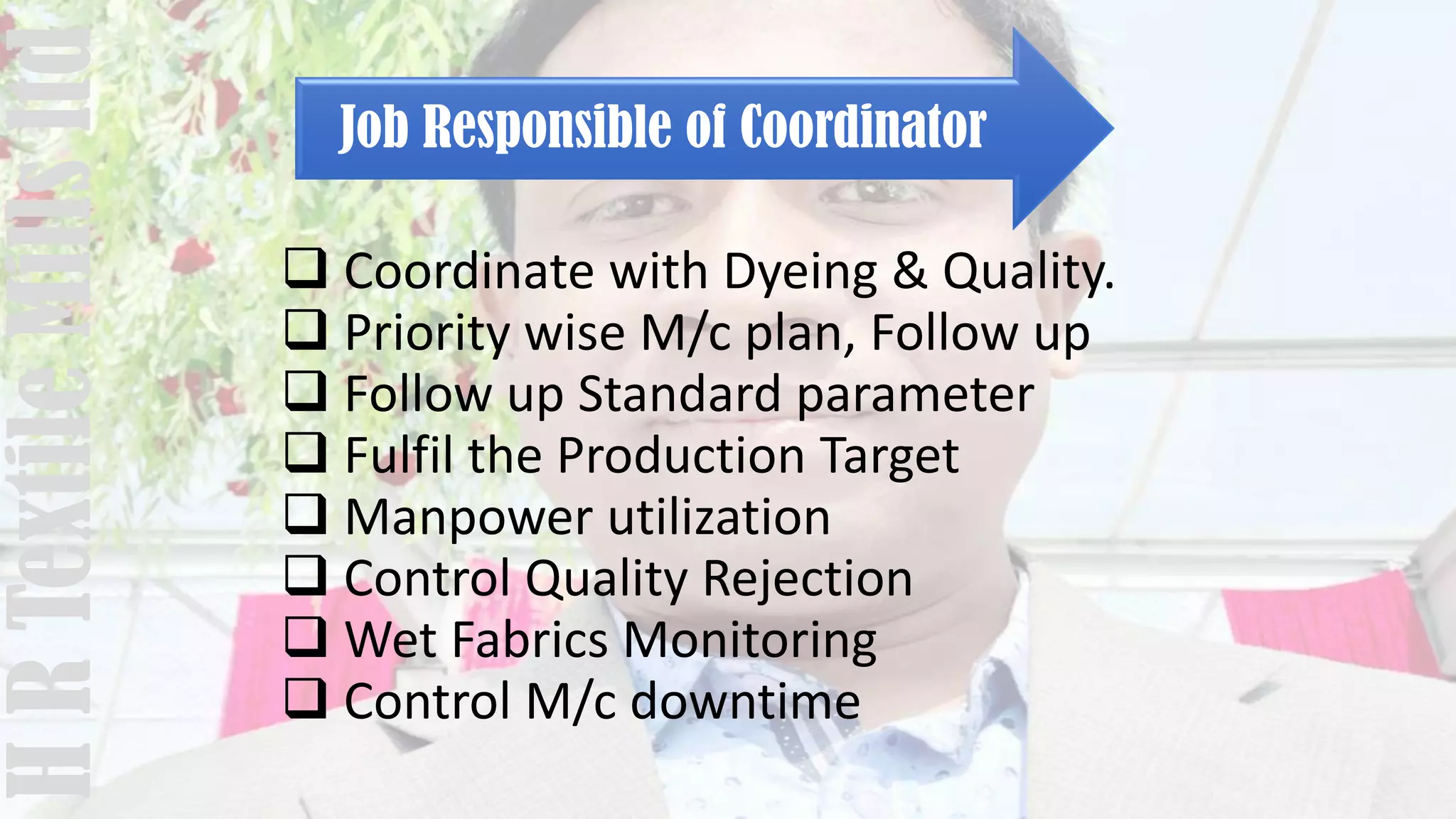

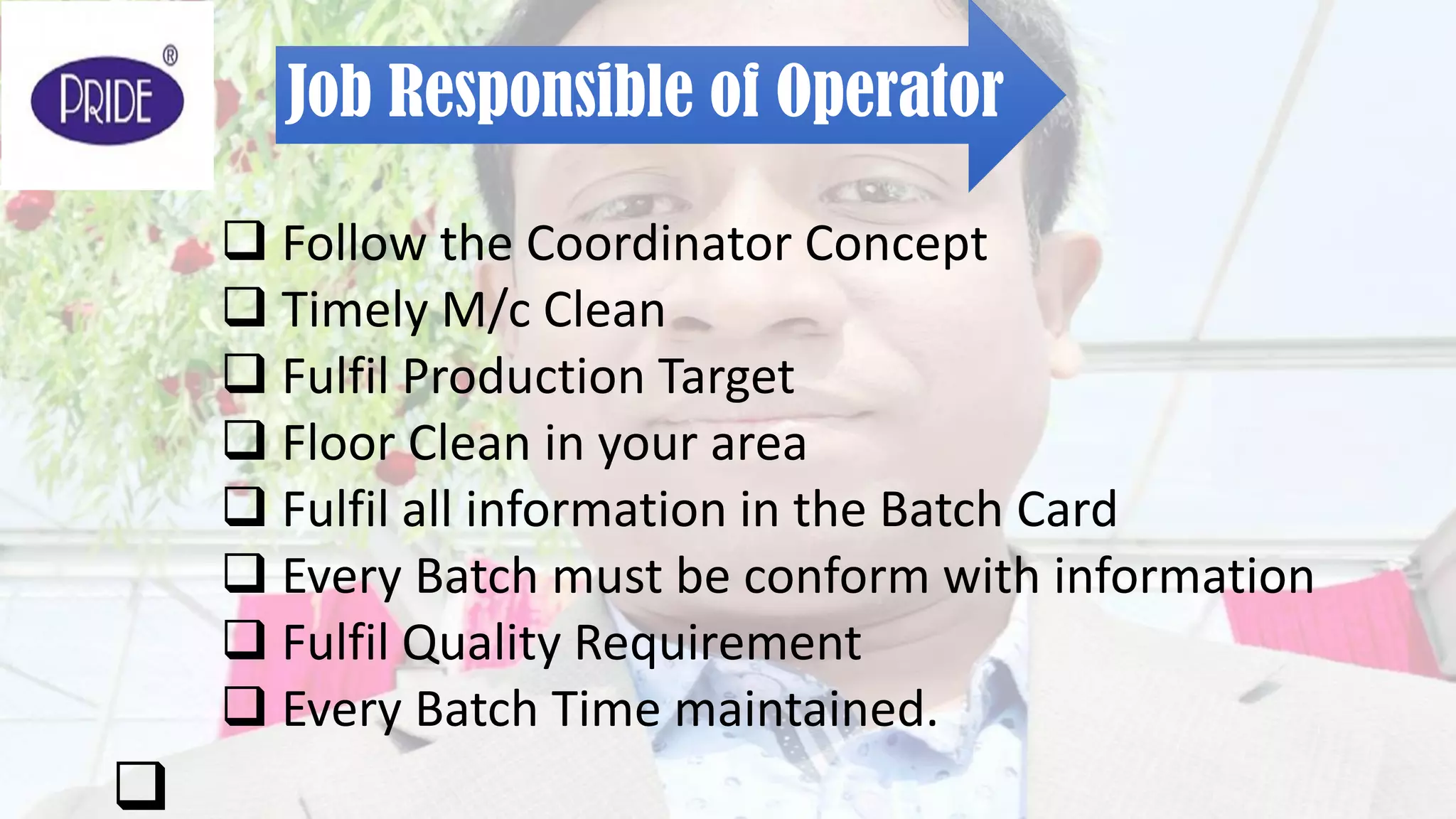

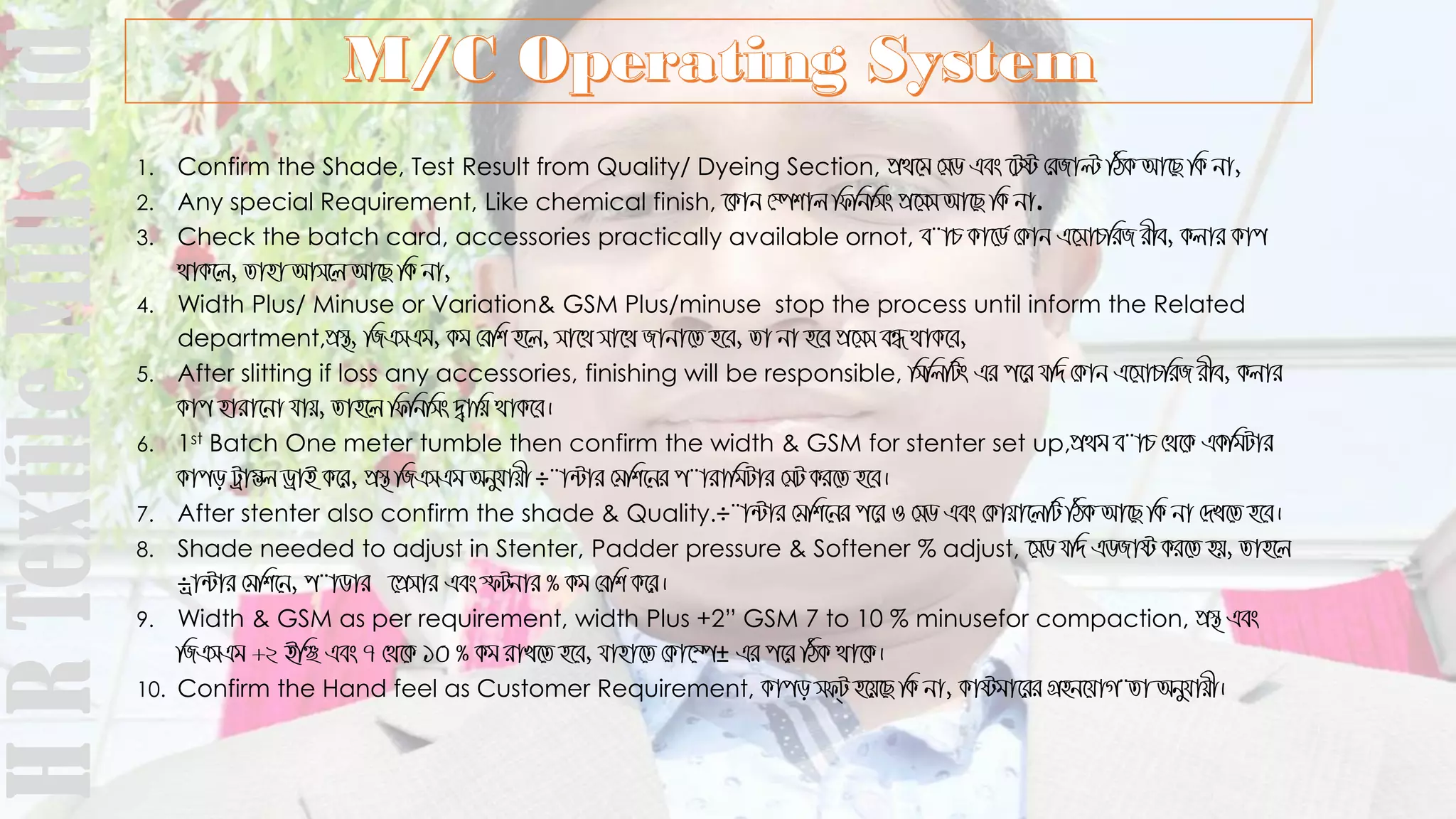

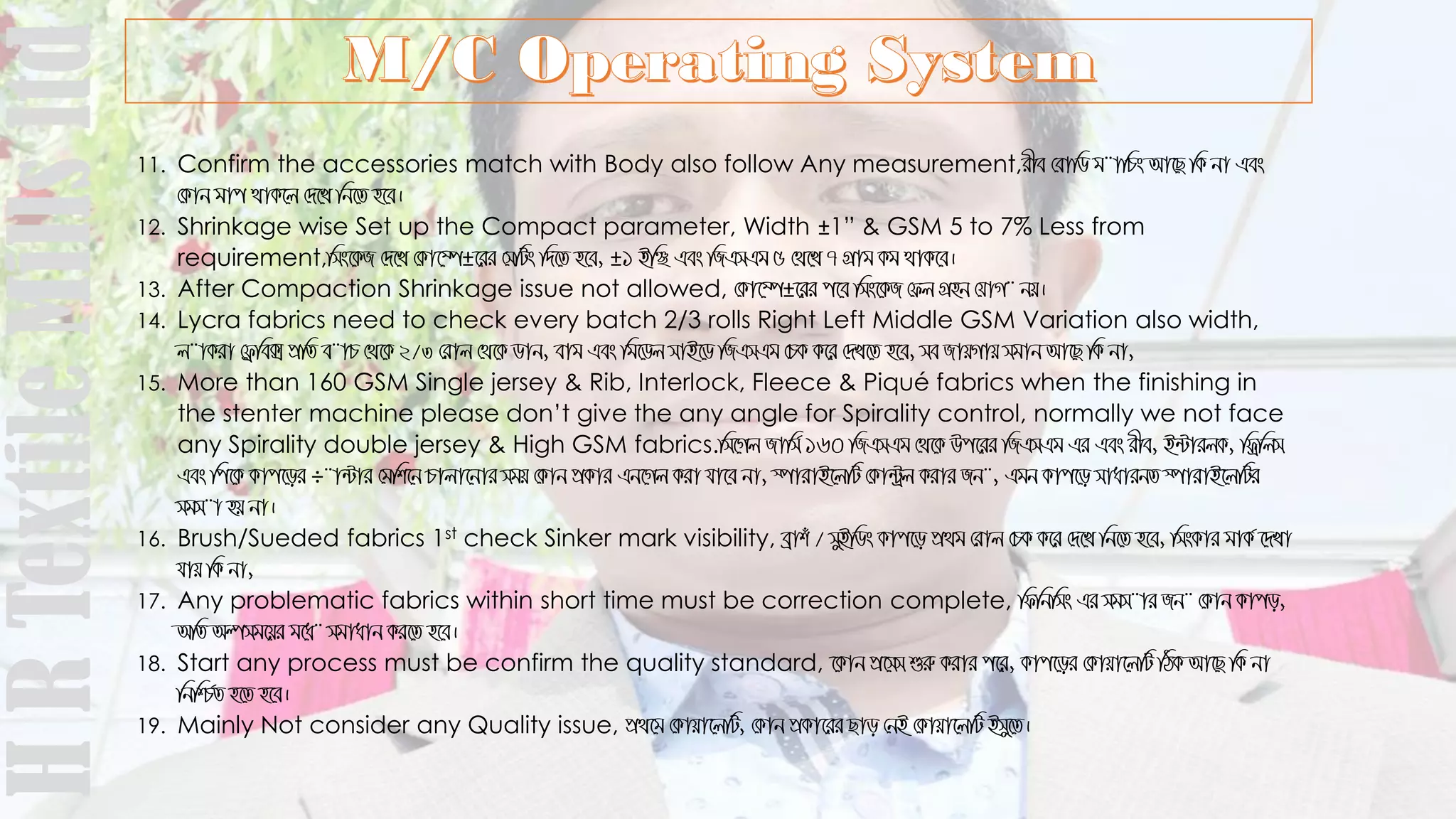

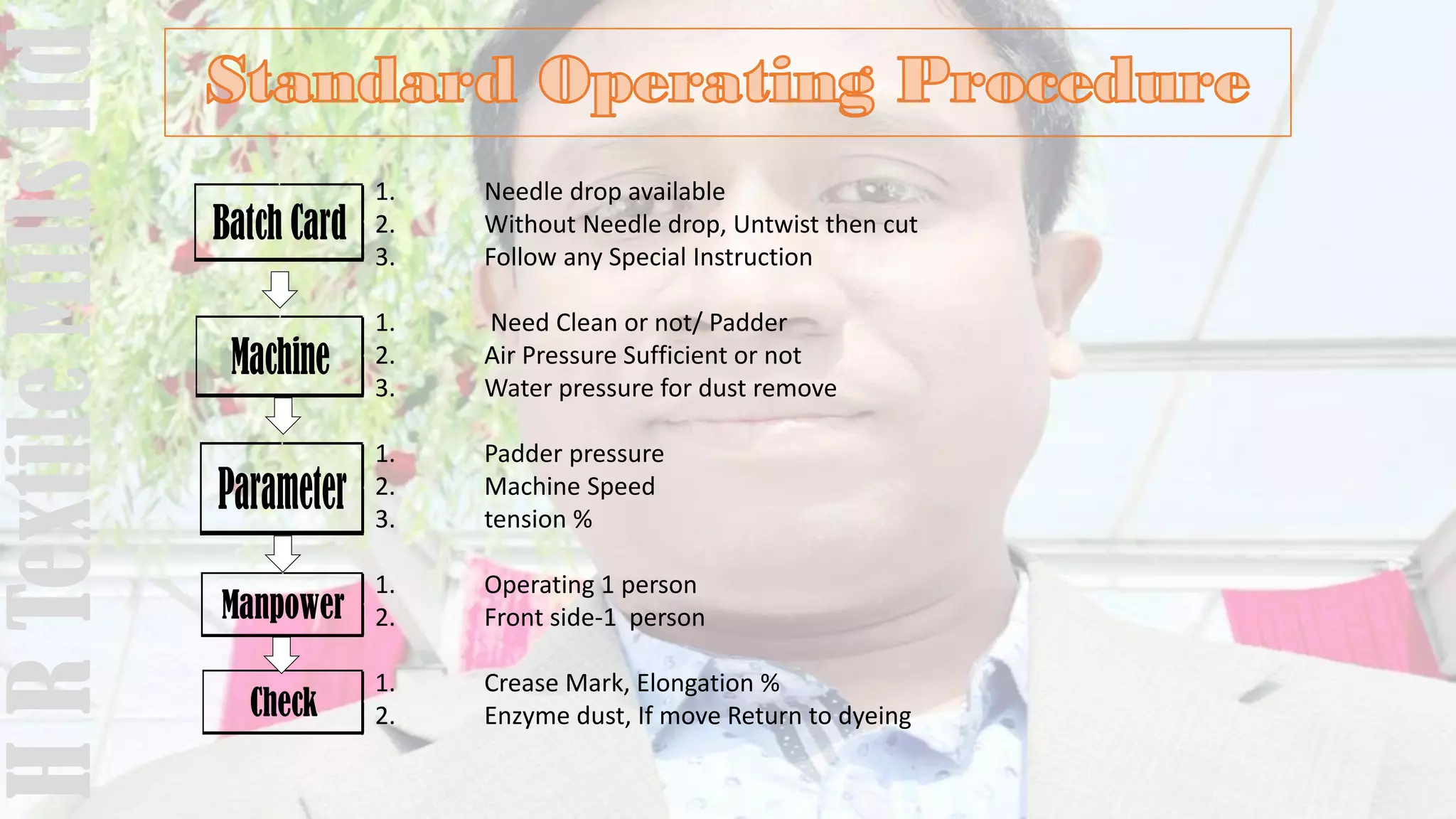

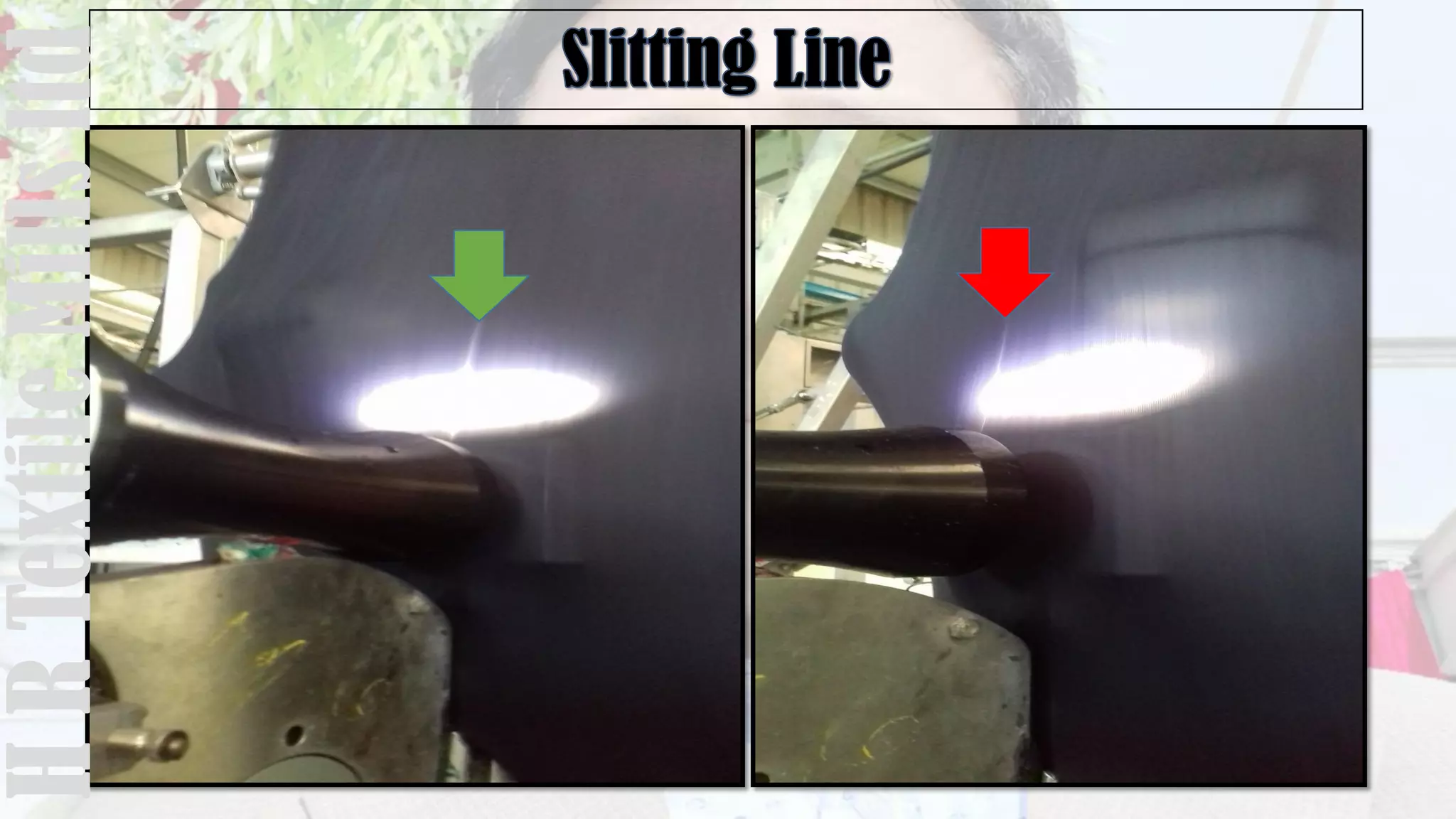

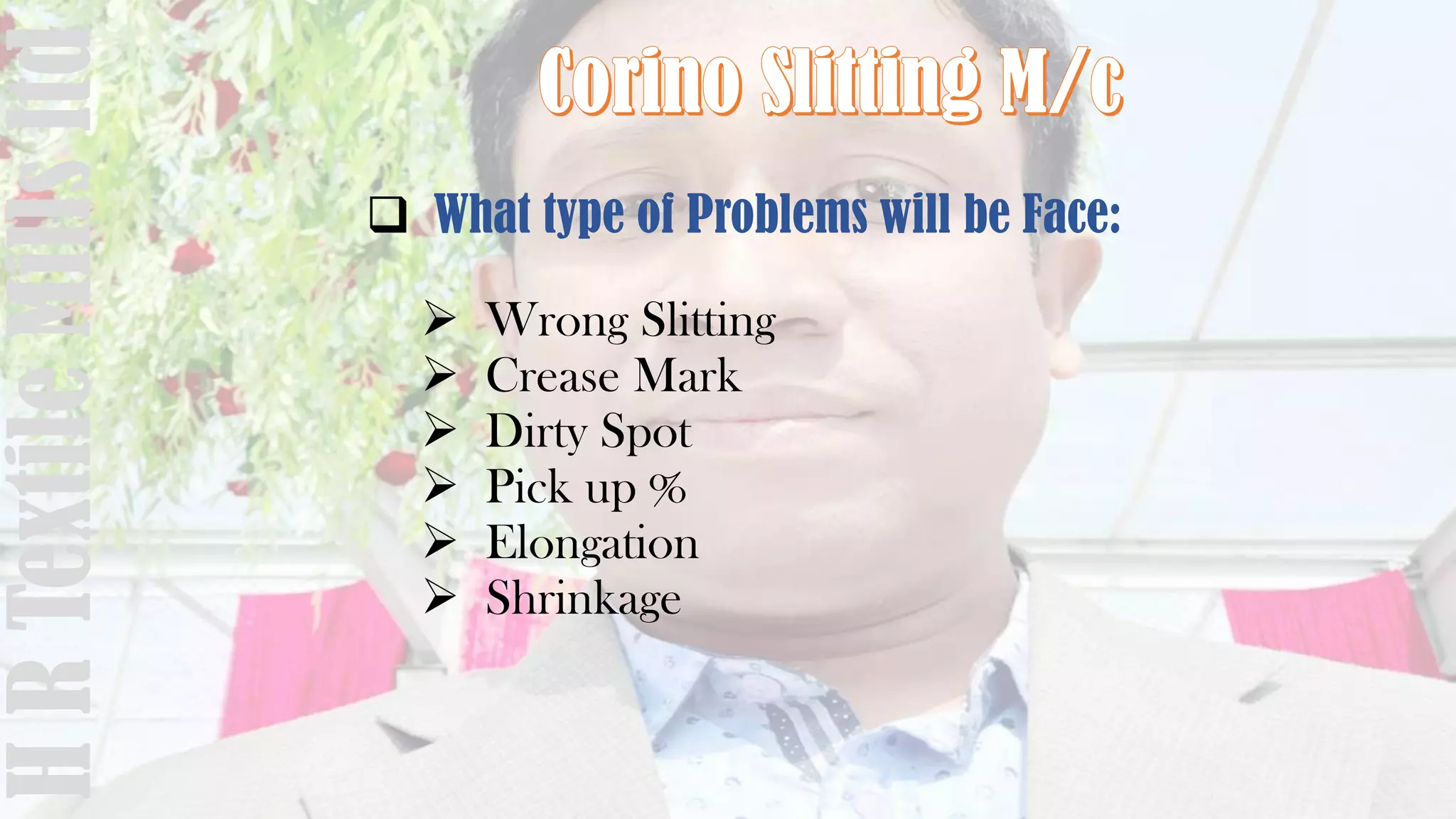

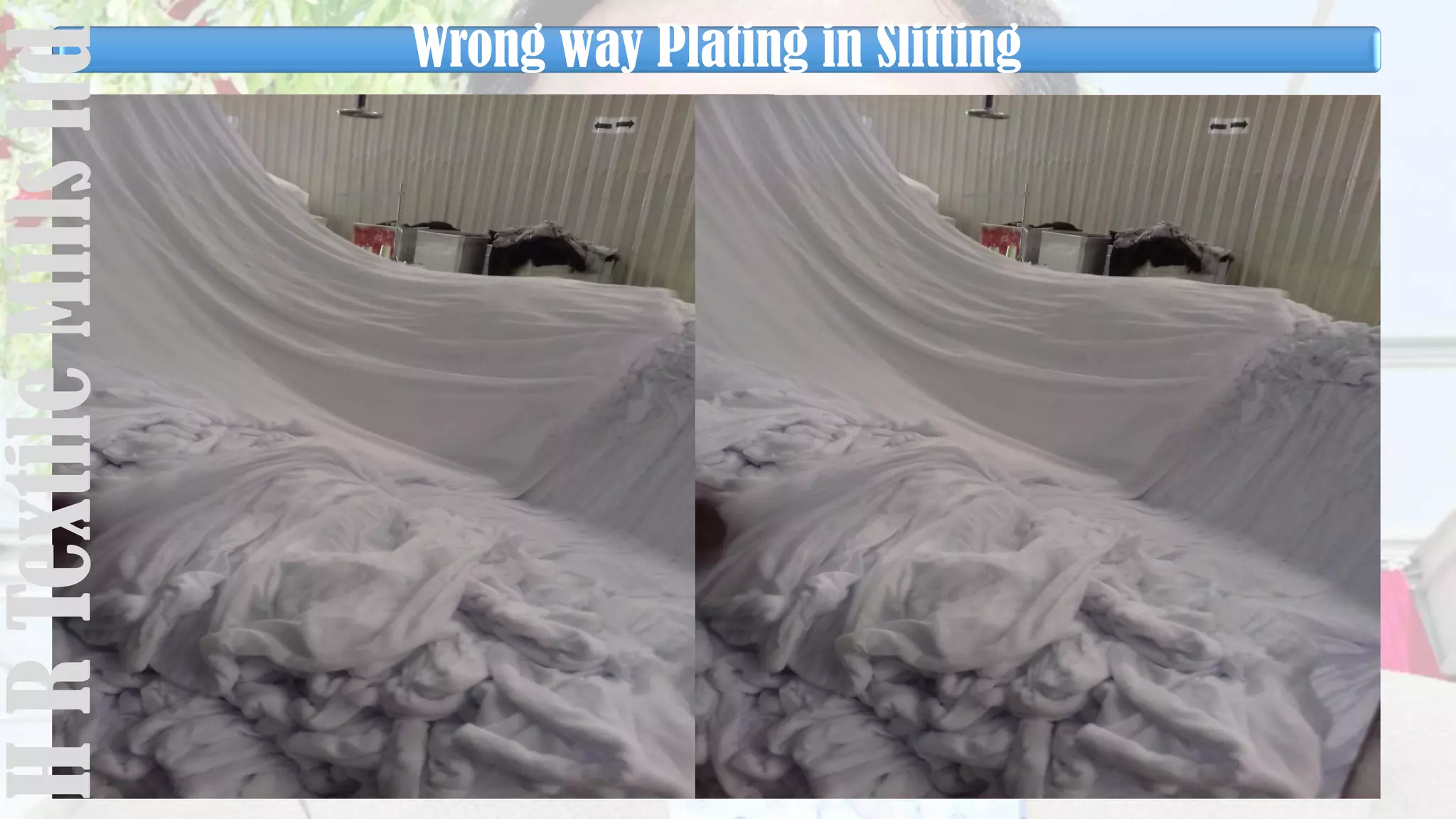

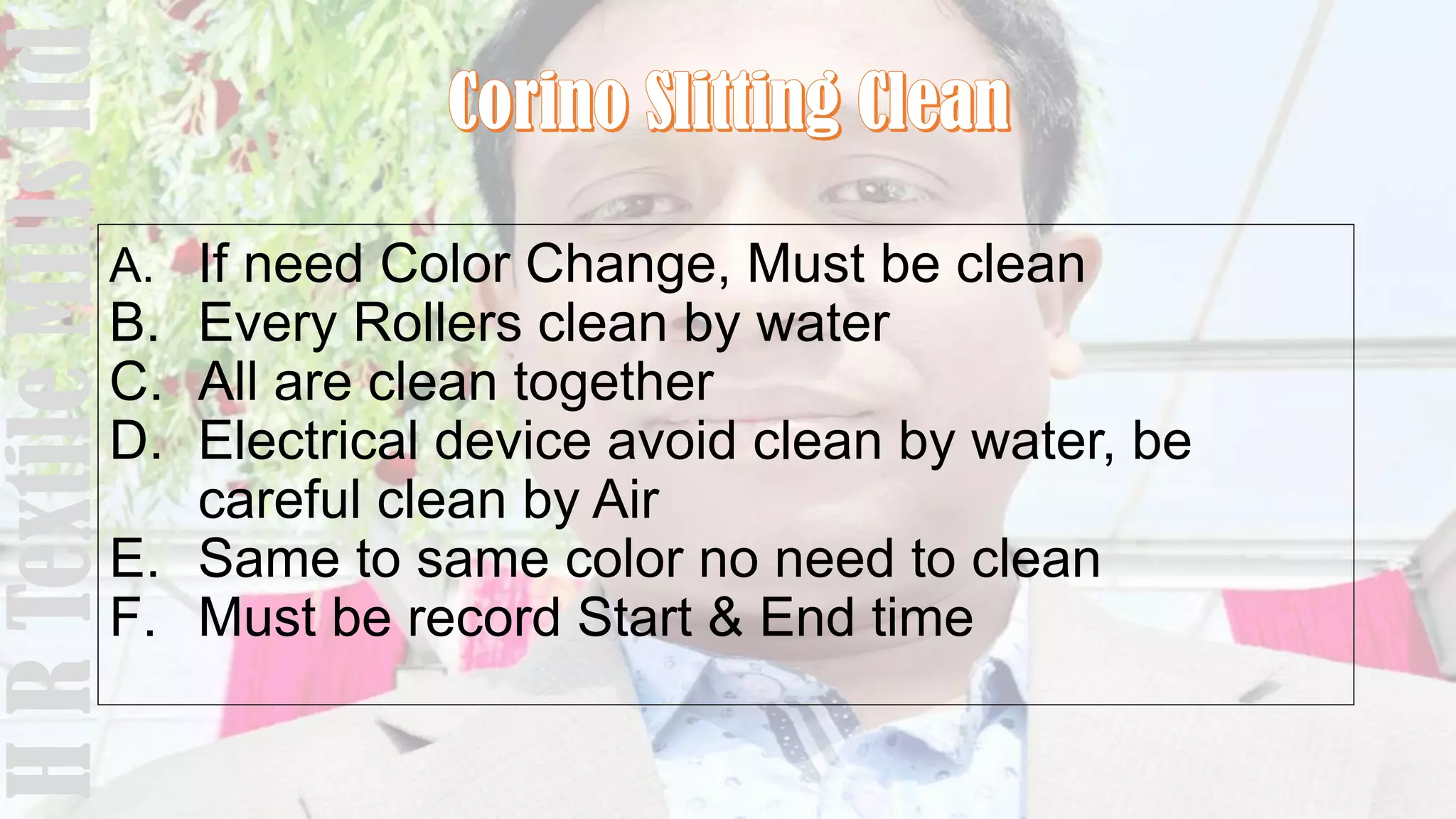

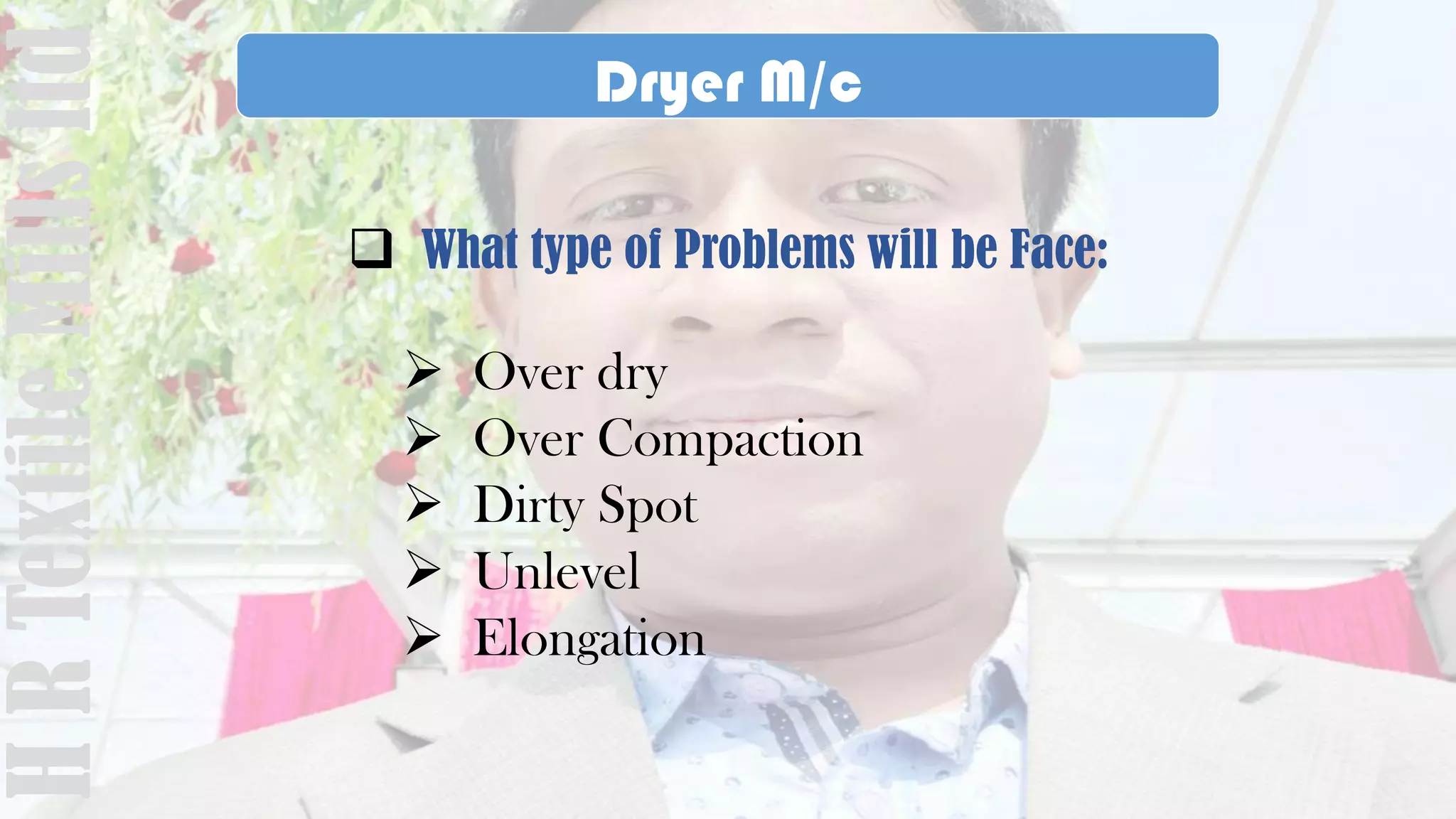

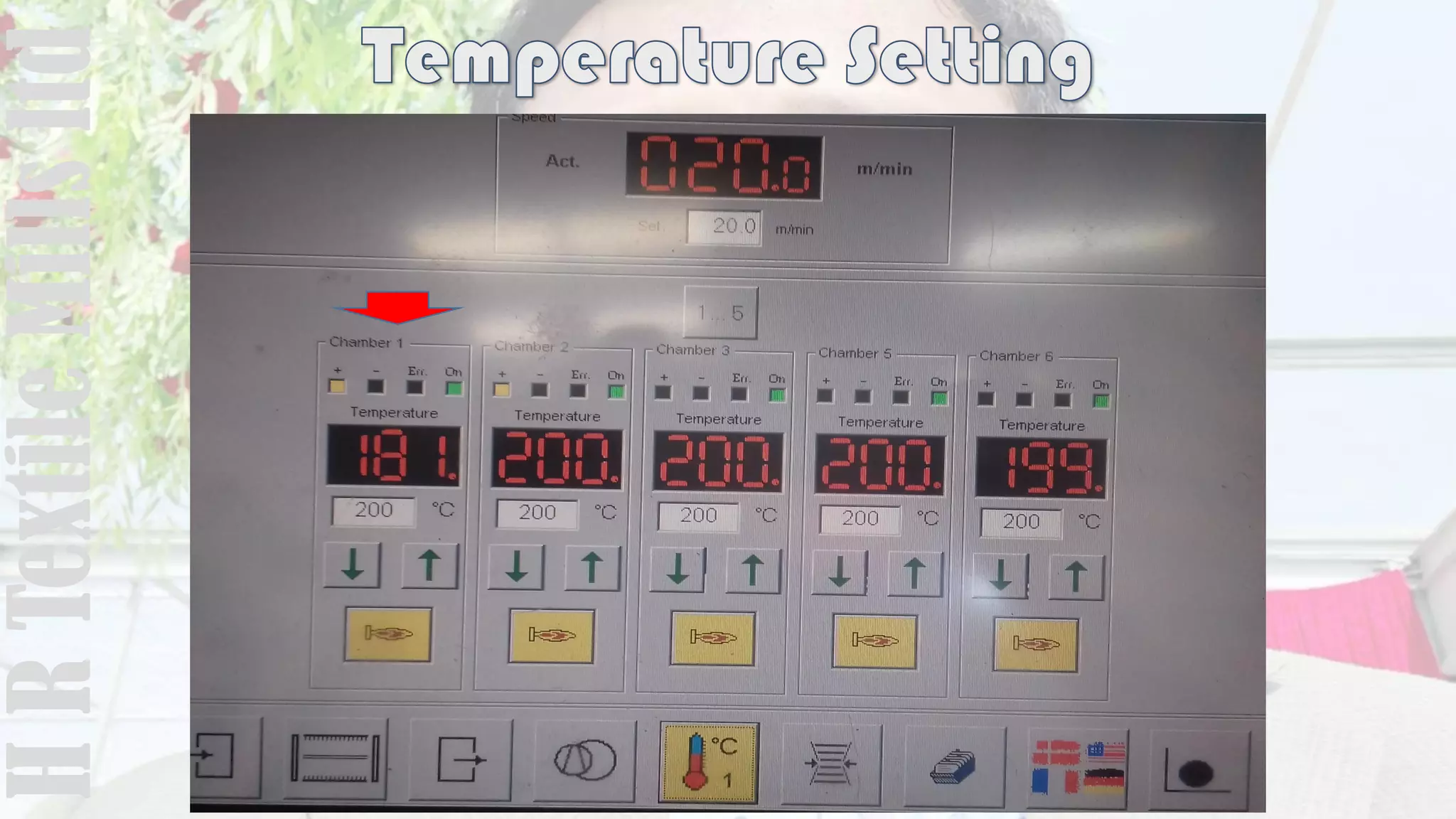

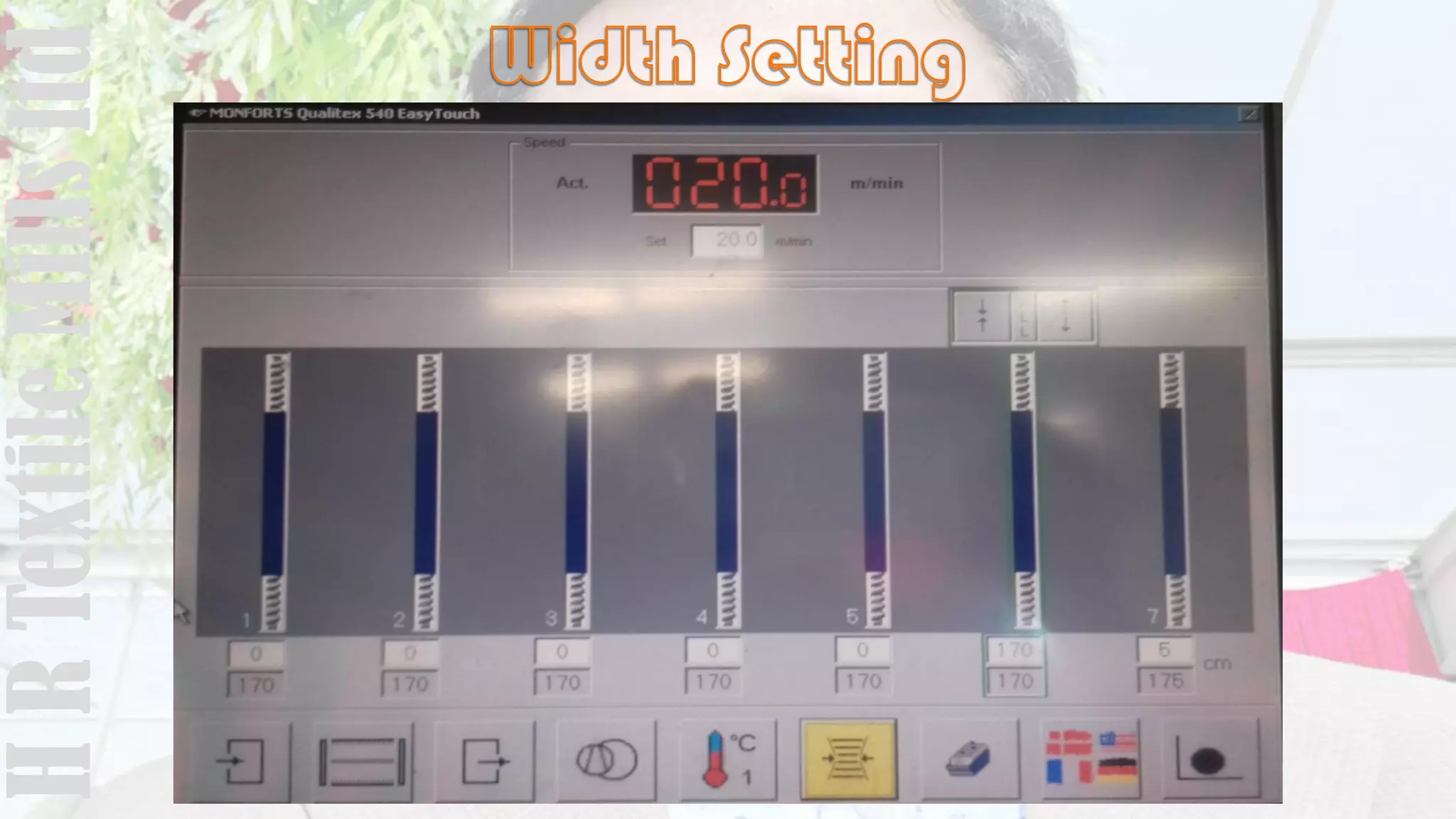

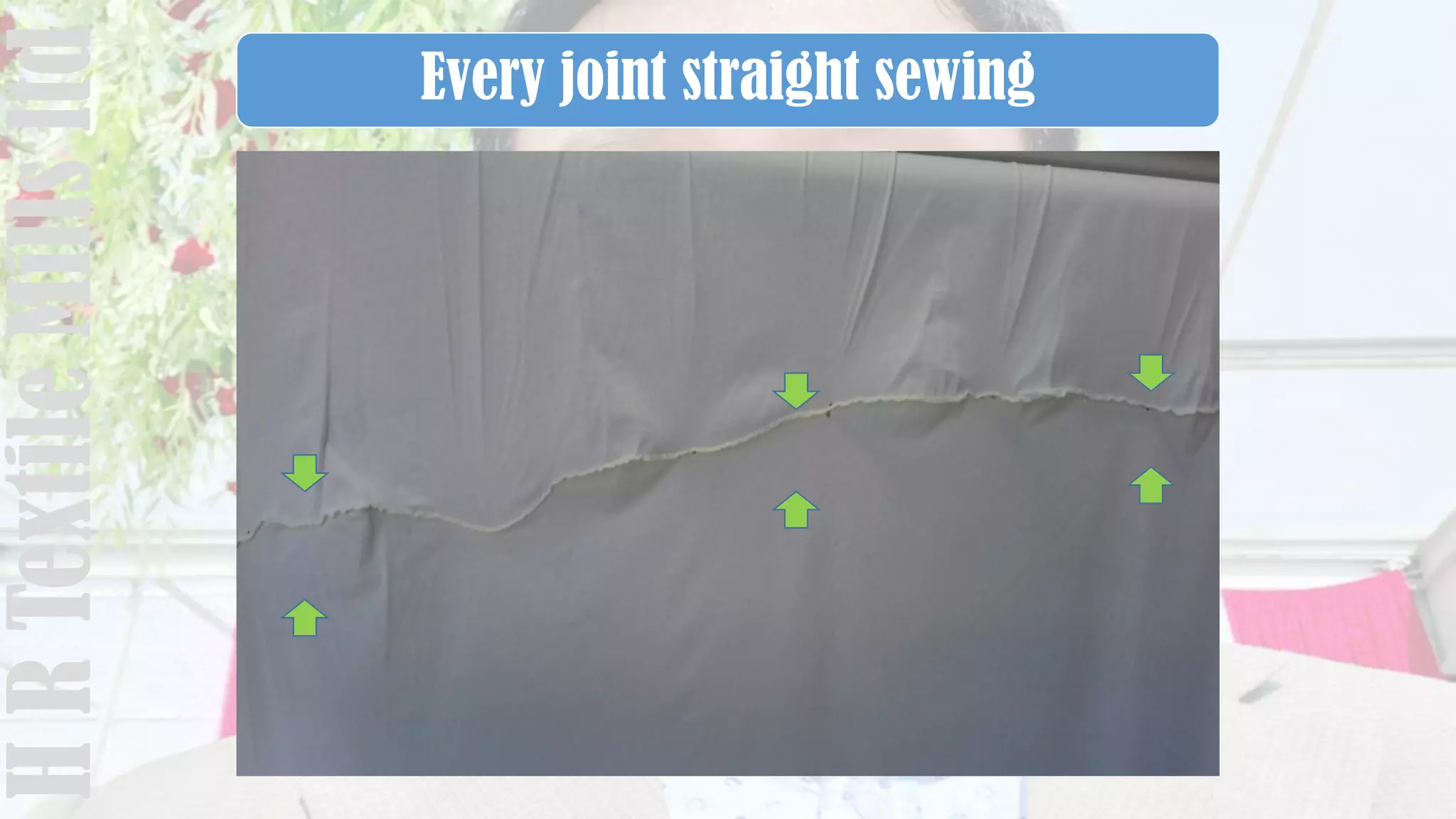

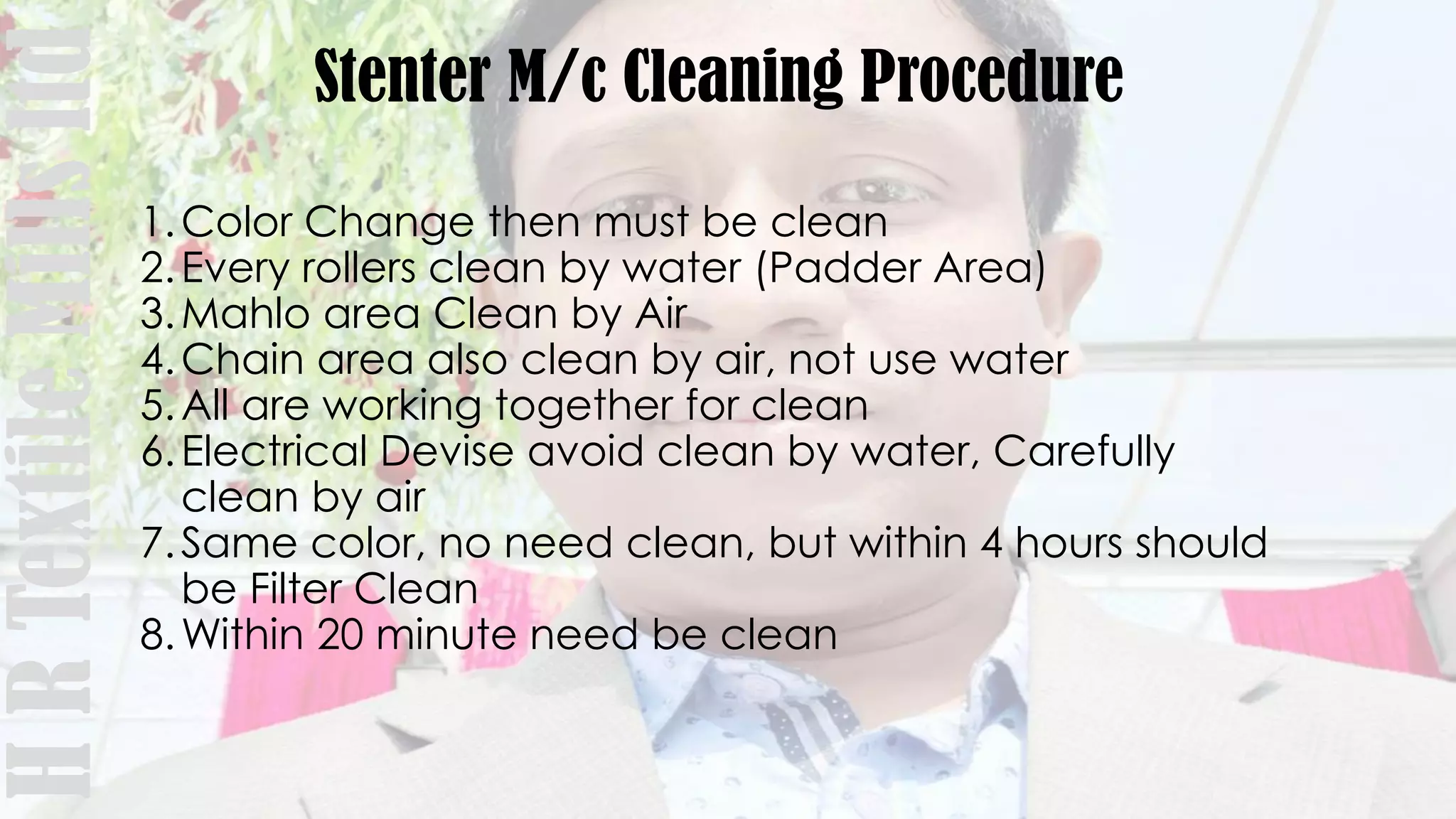

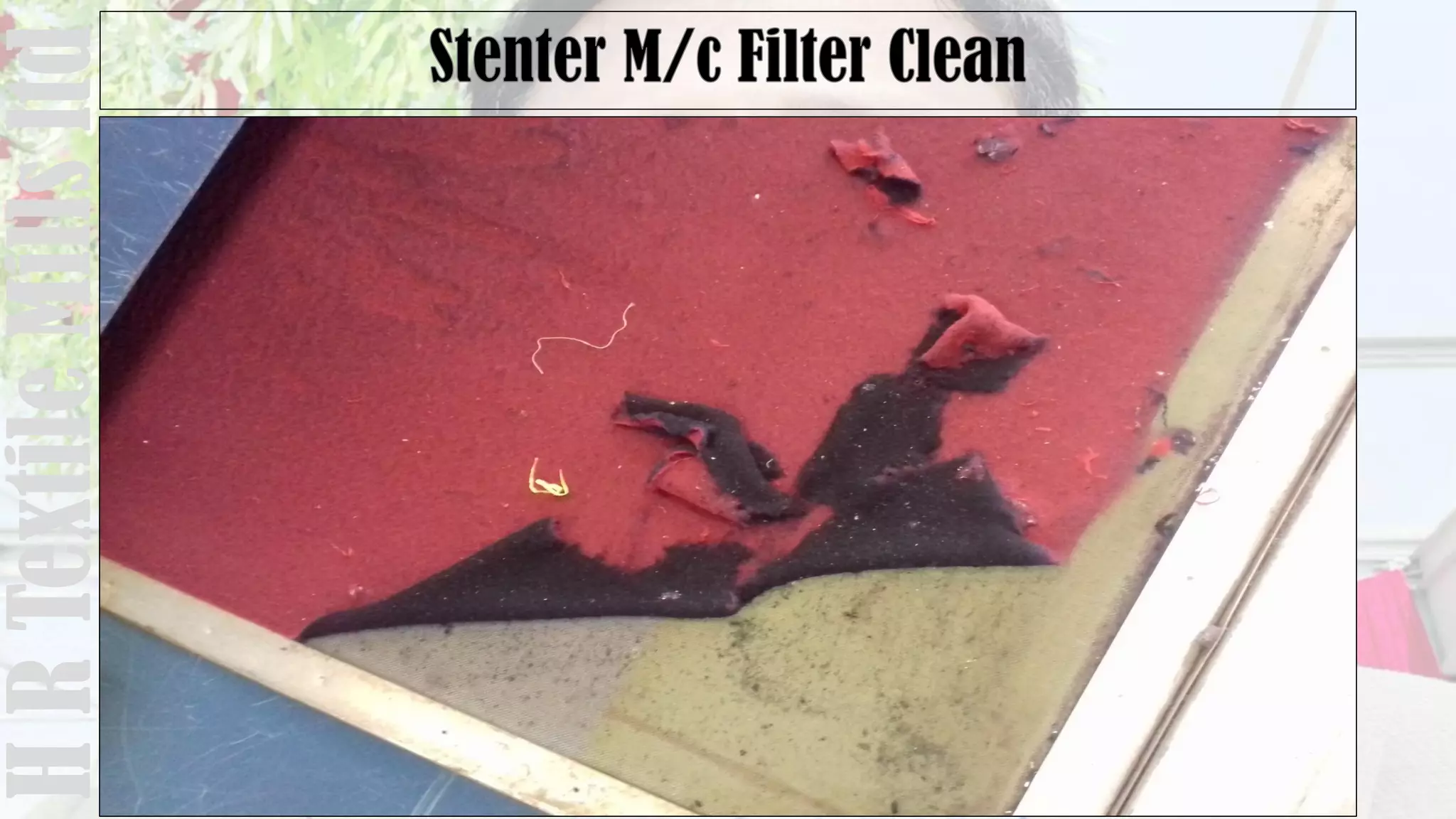

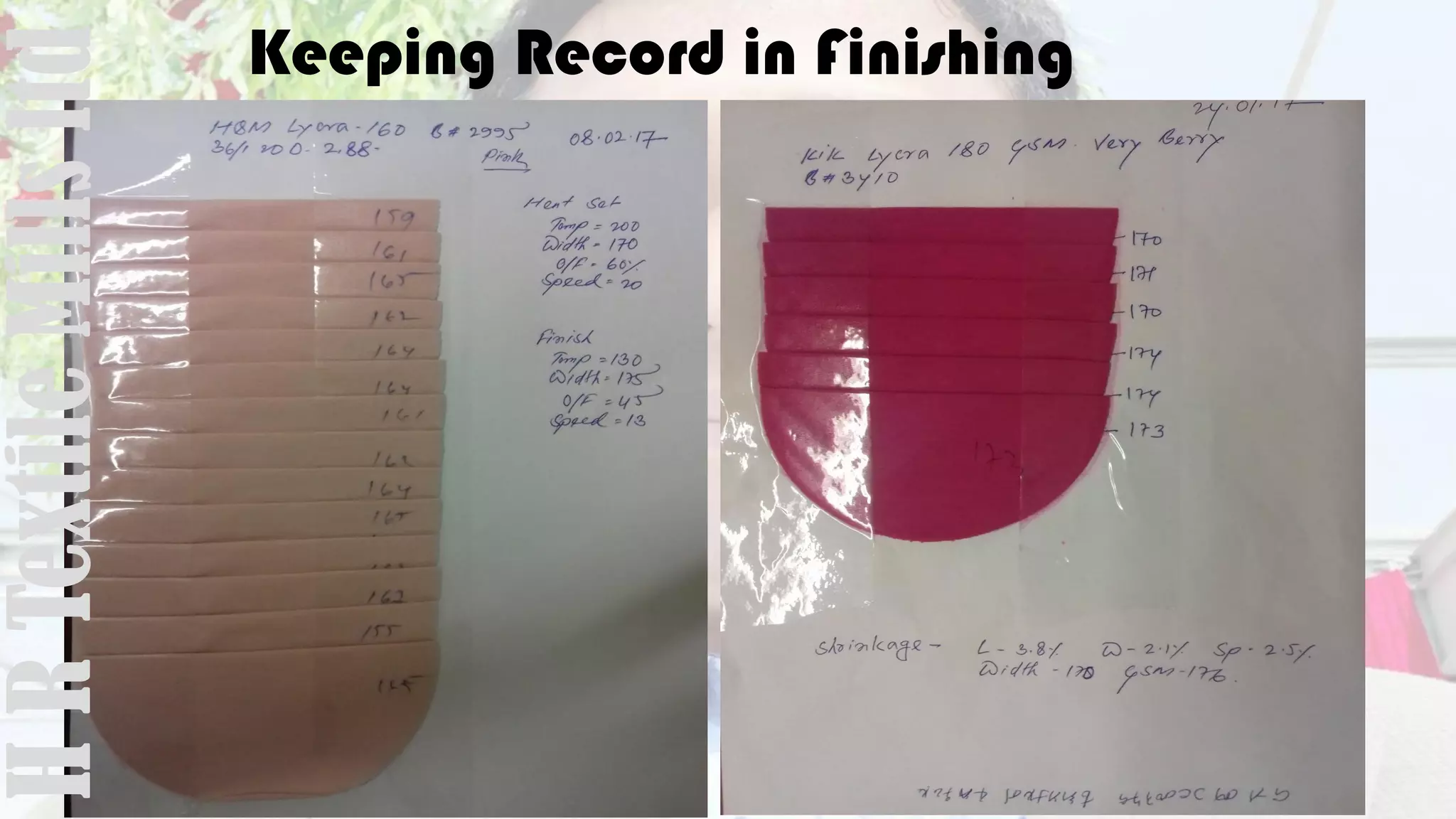

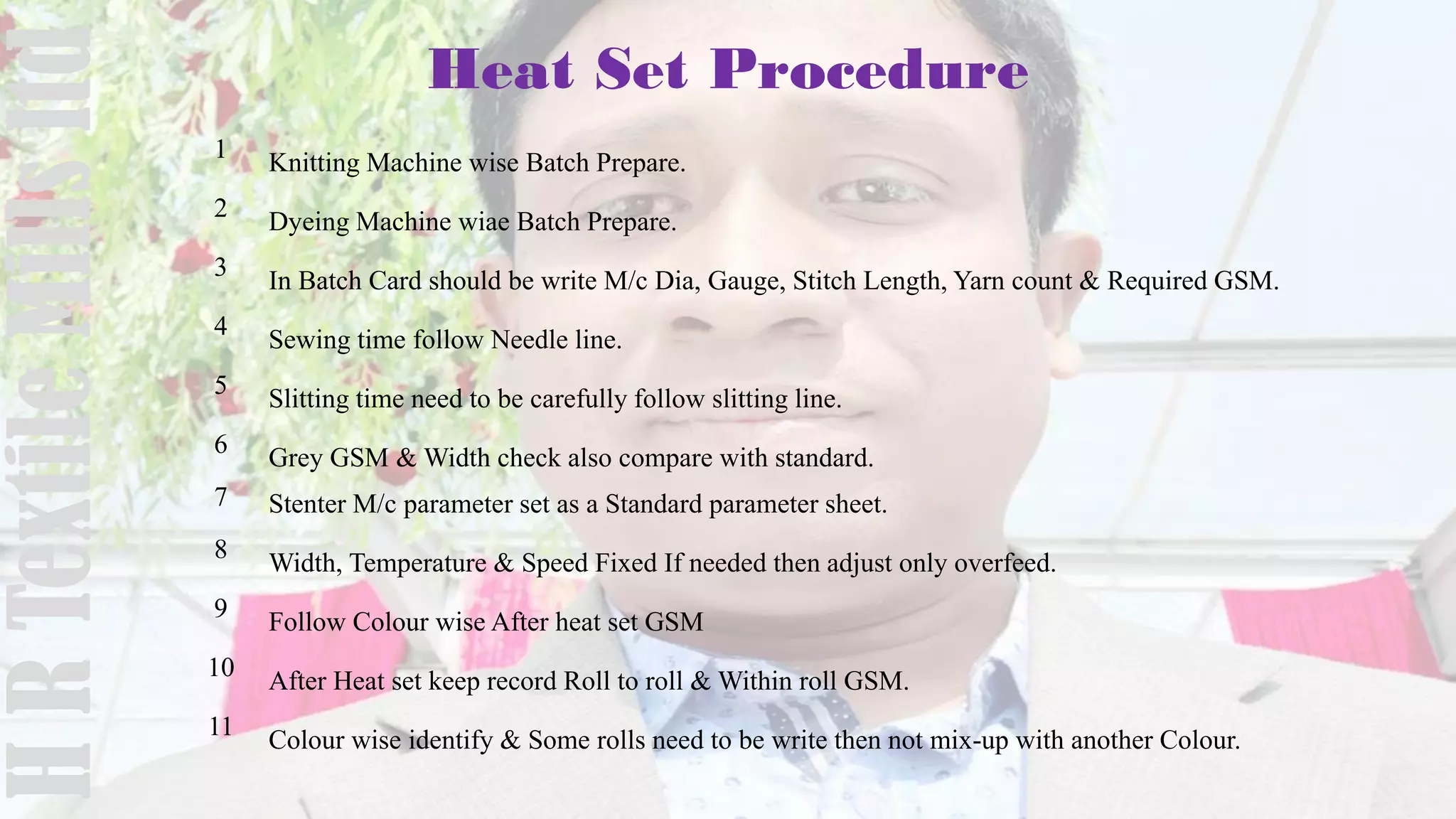

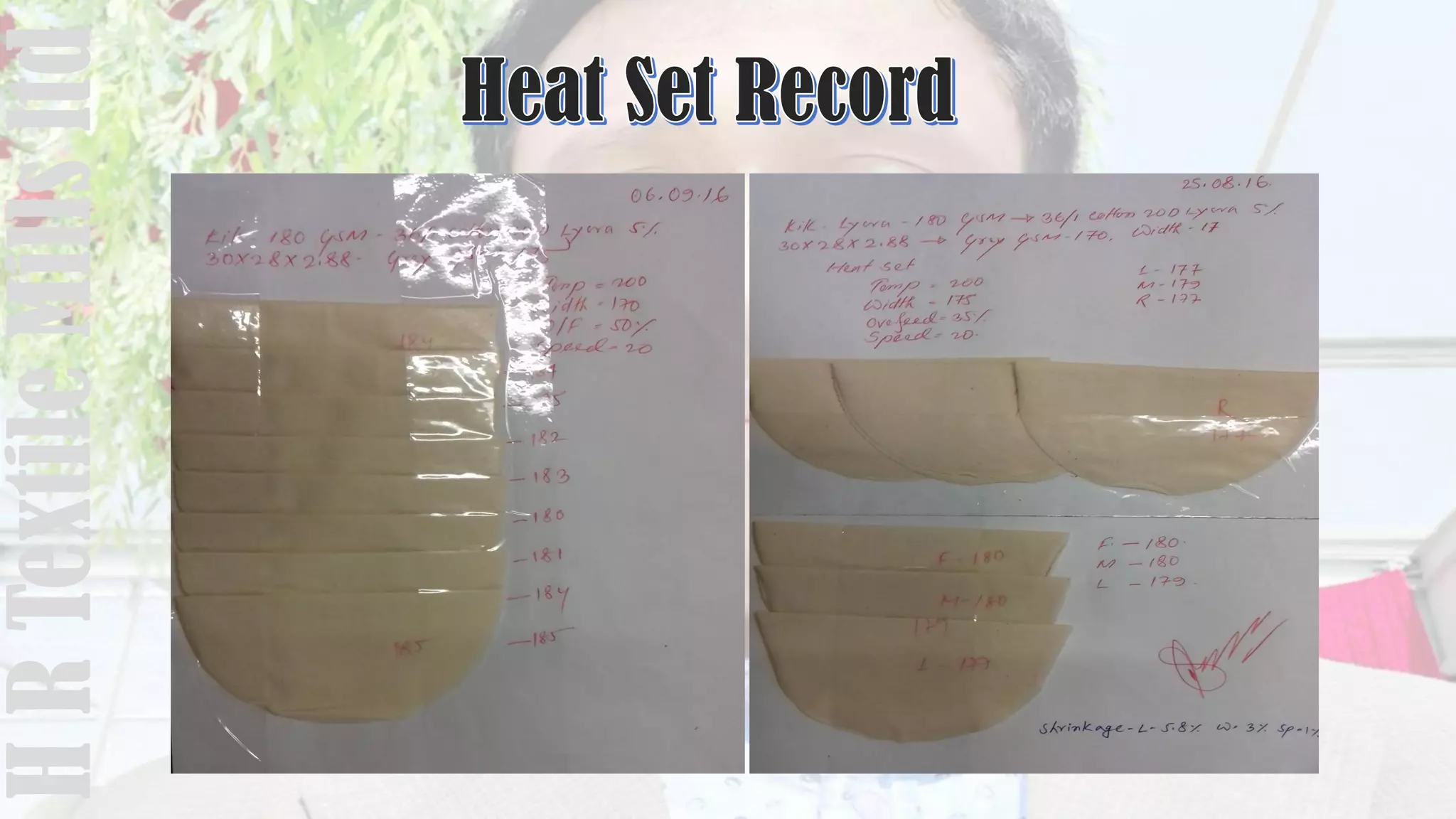

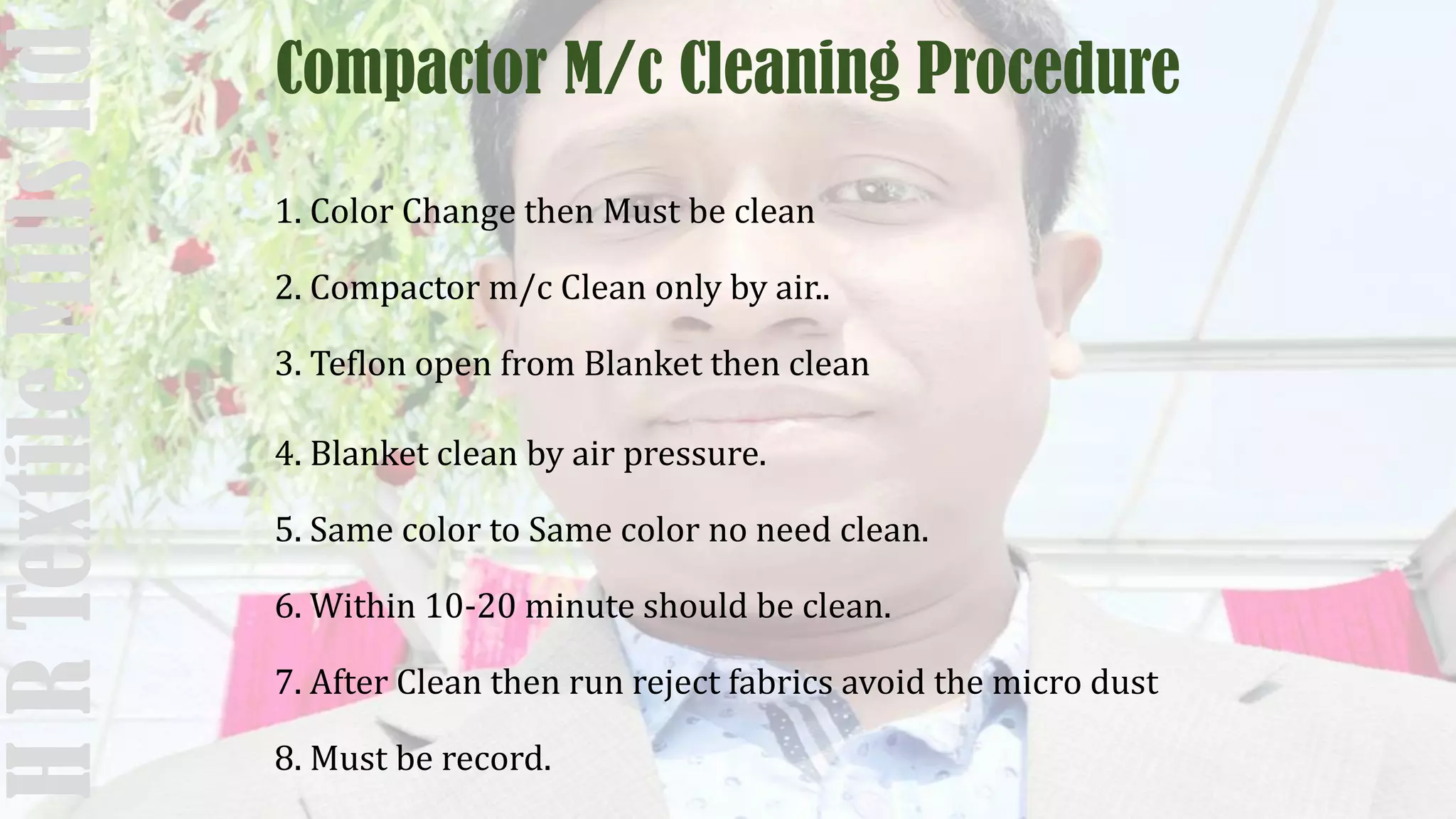

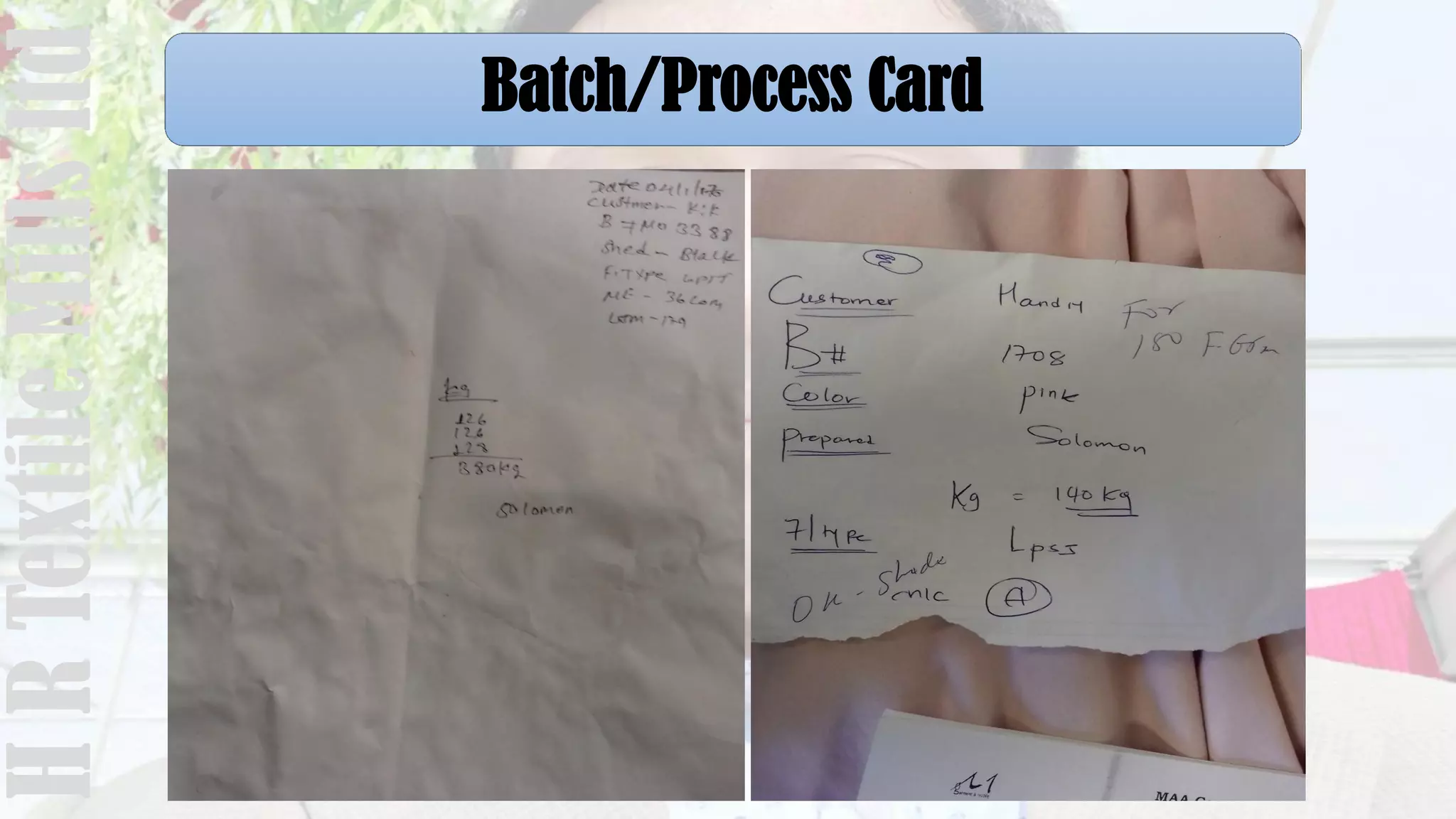

This document outlines the job responsibilities and standard operating procedures for coordinators and operators in the fabrics finishing department of HR Textile Mills Ltd. It details the responsibilities of coordinators such as prioritizing machine plans and quality control, and of operators such as following coordinator instructions and meeting production targets. It then lists 18 specific steps for quality control and production requirements that must be followed in various stages of the finishing process such as slitting, dyeing, stenting, compacting and brushing.