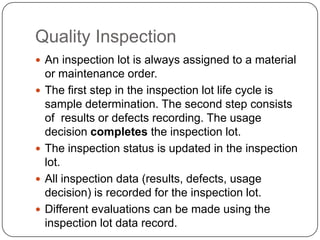

1. The quality inspection process involves generating an inspection lot number, recording inspection results, and making a usage decision to complete the inspection lot.

2. Key steps include sample determination, results recording, and updating the inspection lot status with all inspection data.

3. The quality management module provides continuous improvement tools like notification processing to implement tasks, find problems and solutions, and analyze defects and causes.