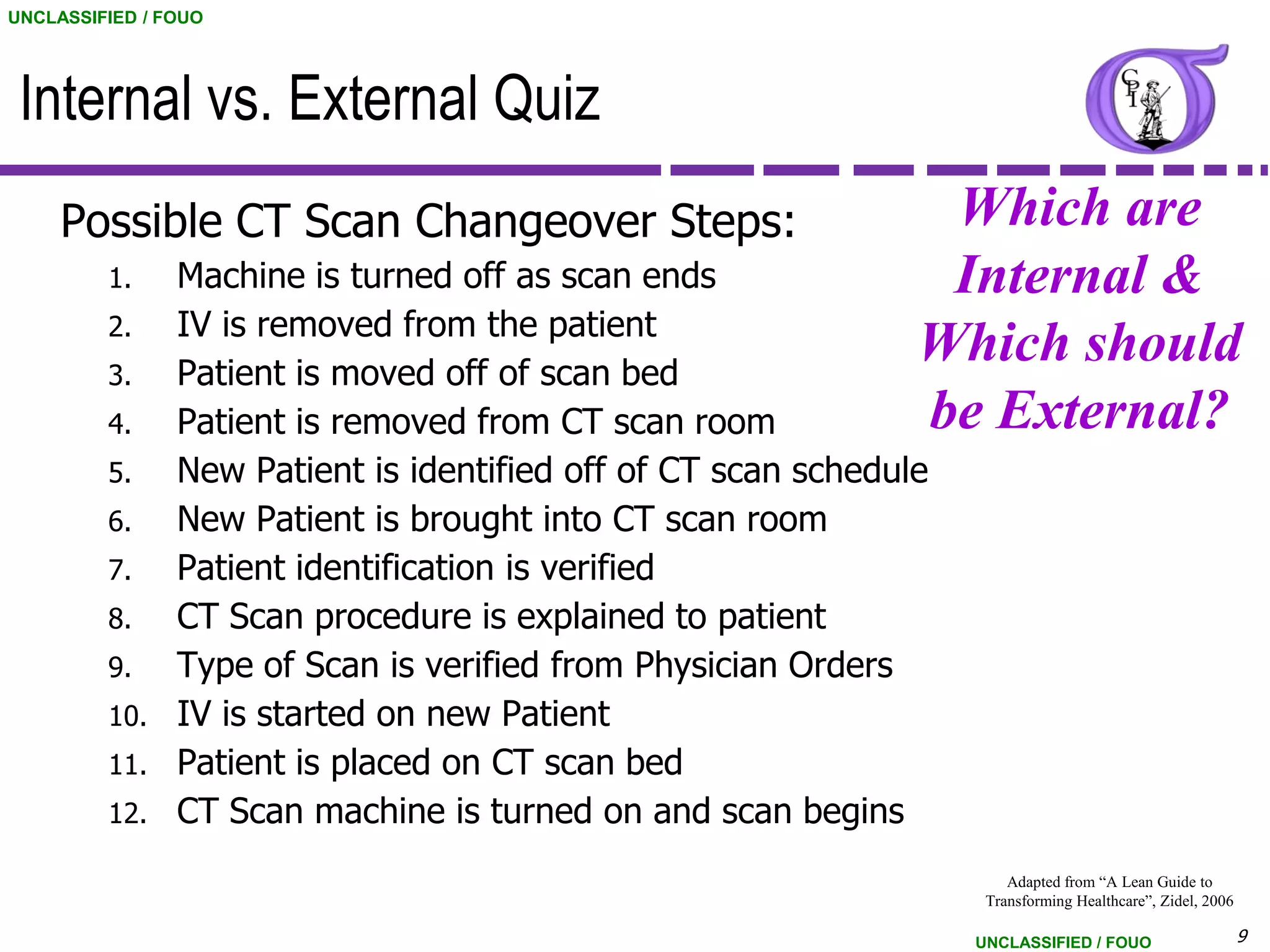

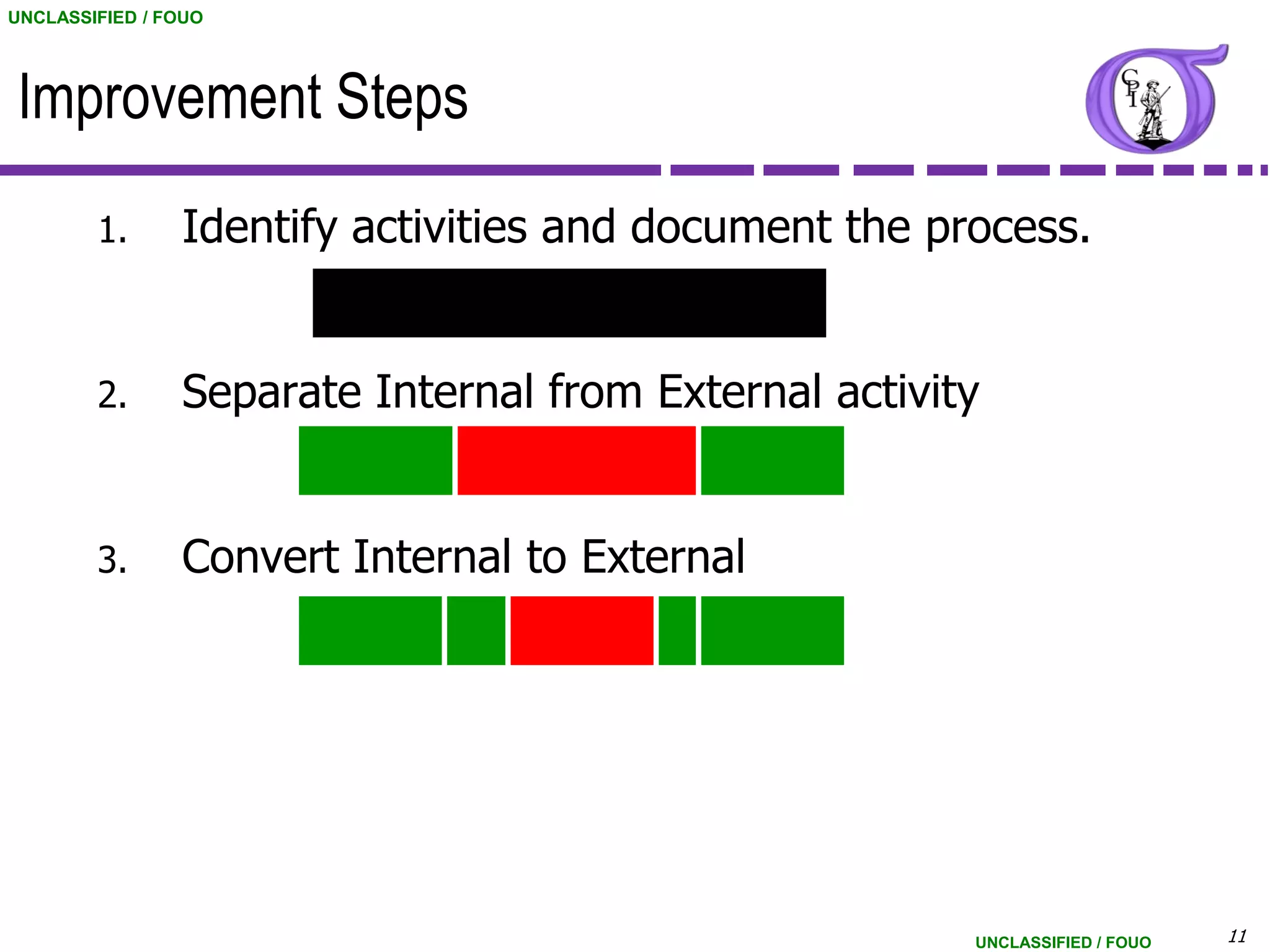

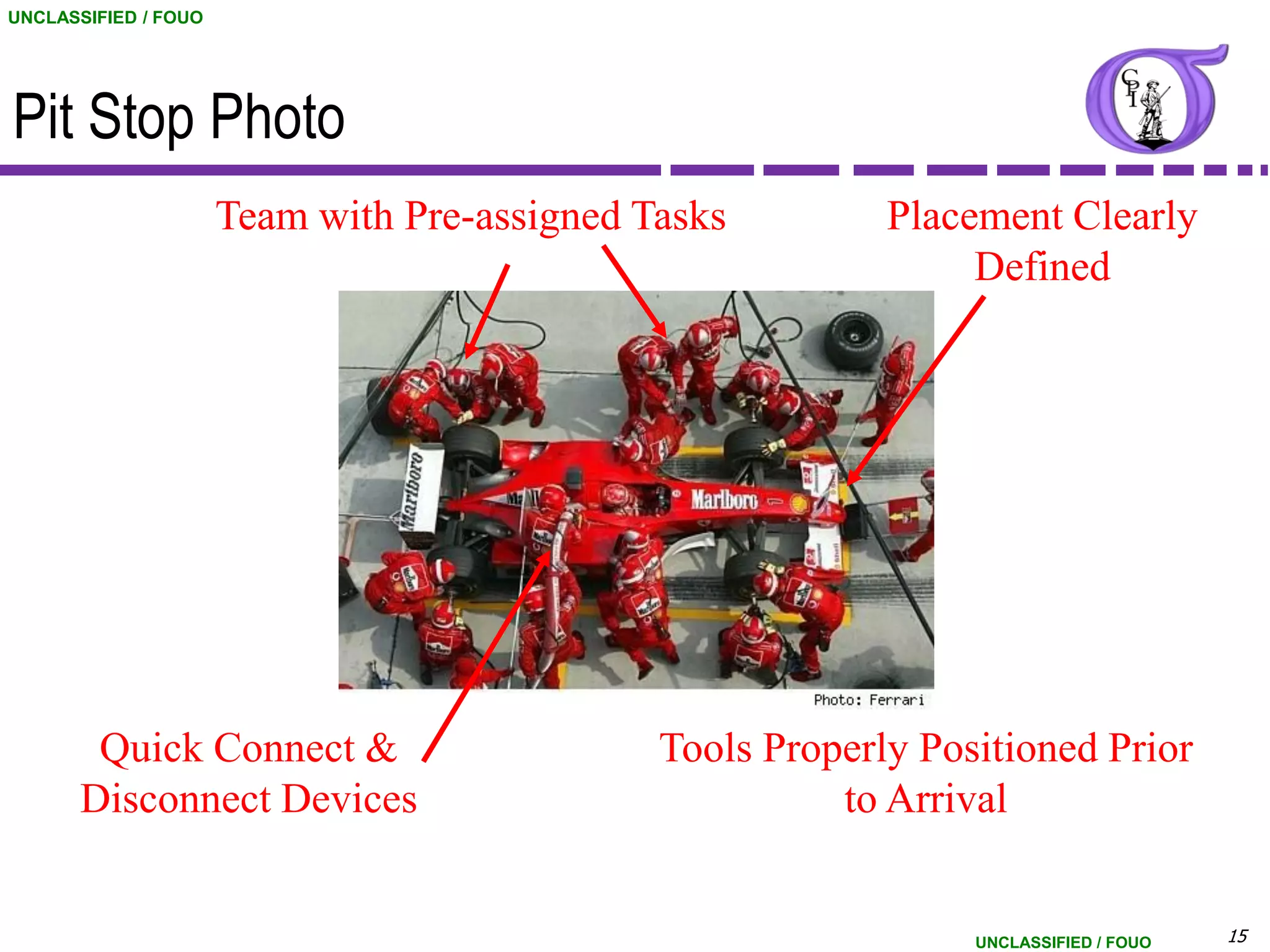

This document discusses quick changeover techniques to improve process efficiency. It begins by outlining an 8-step process improvement methodology. It then defines changeover times and differentiates between traditional and continuous process improvement thinking regarding changeovers. The document explains that quick changeovers can decrease downtime and waste, allowing for increased flexibility through smaller batch sizes. It provides steps to identify internal and external changeover activities, convert internal activities to external to reduce downtime, and further reduce all remaining activities through techniques like parallel operations and automation.