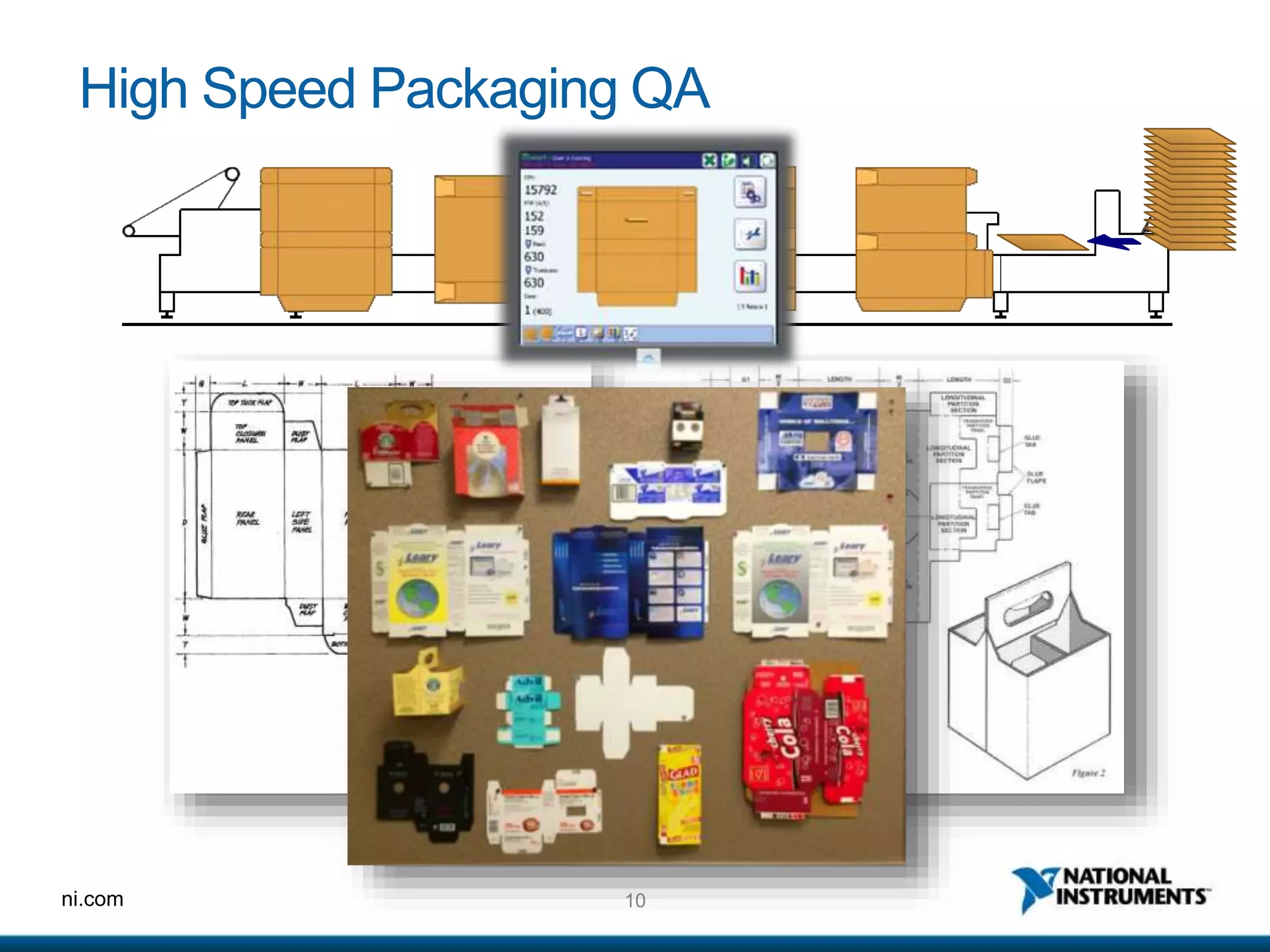

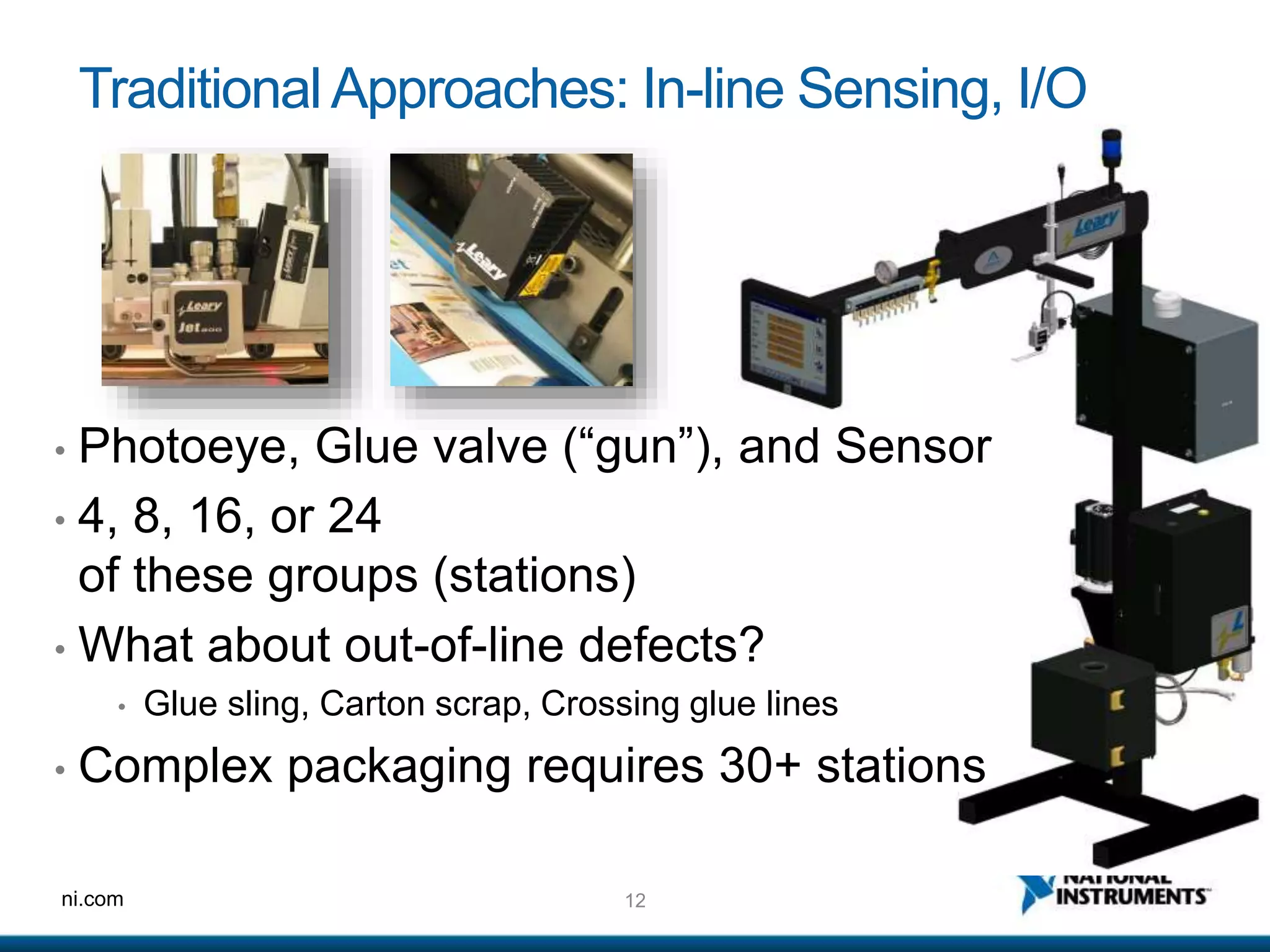

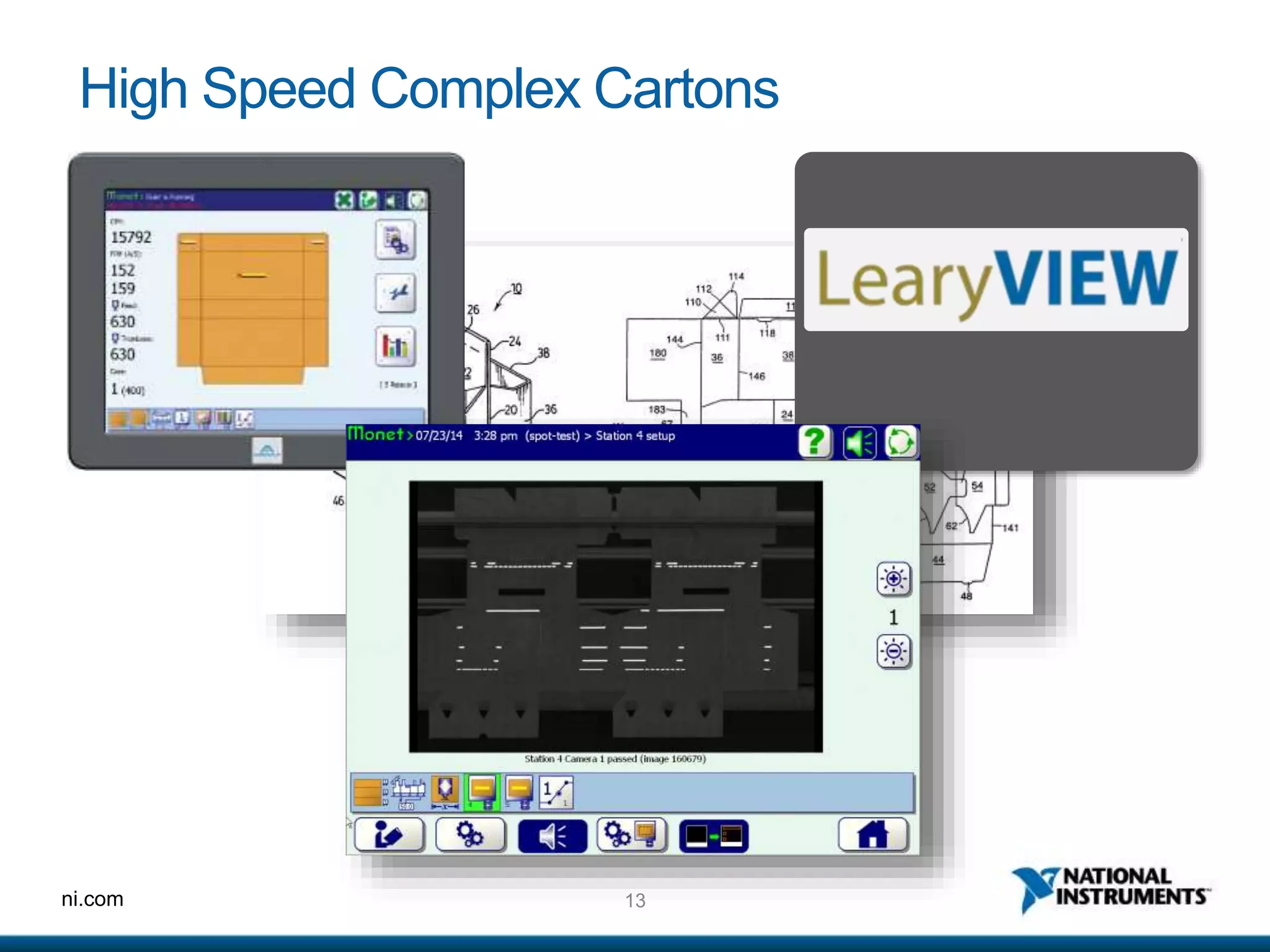

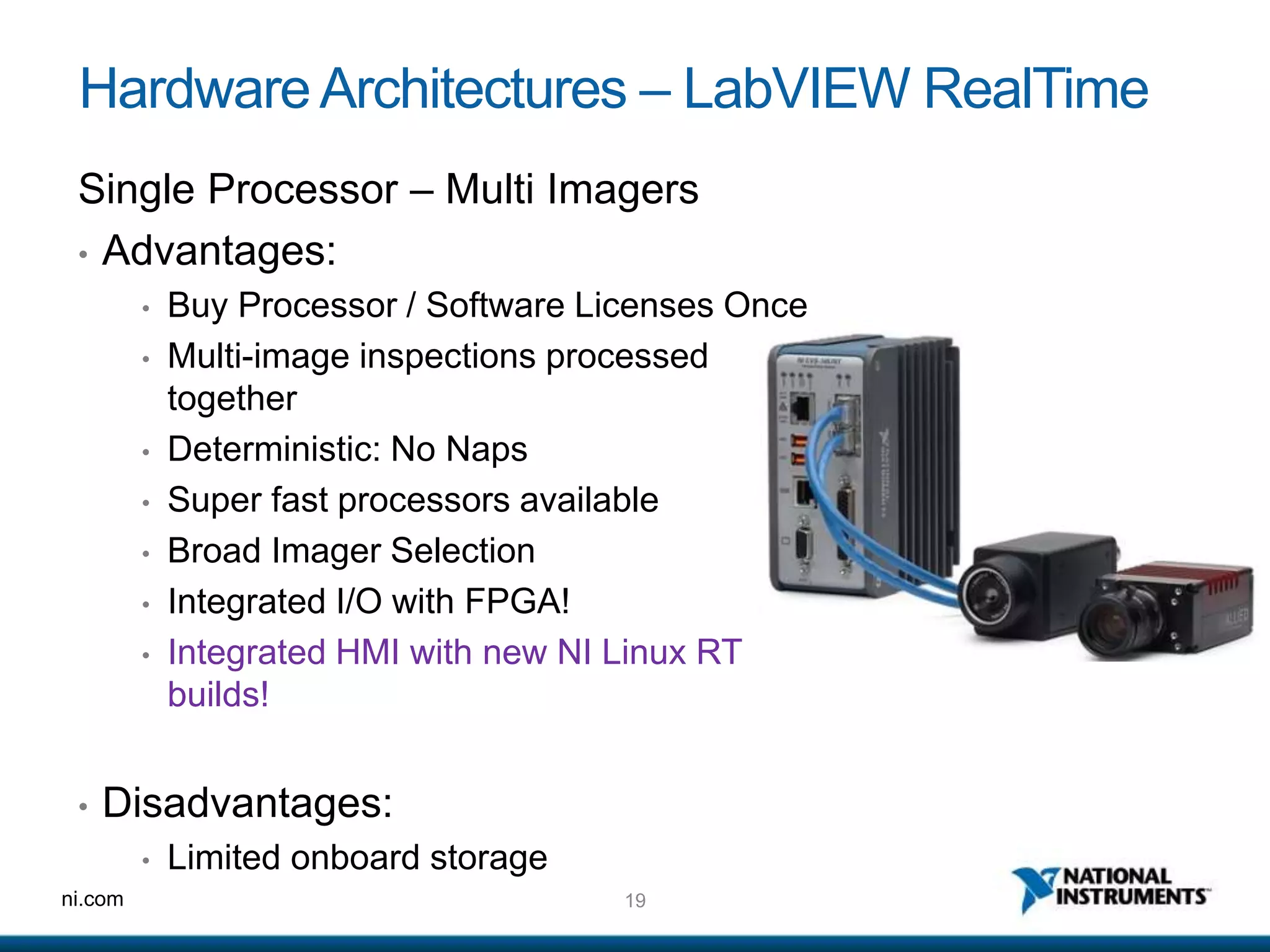

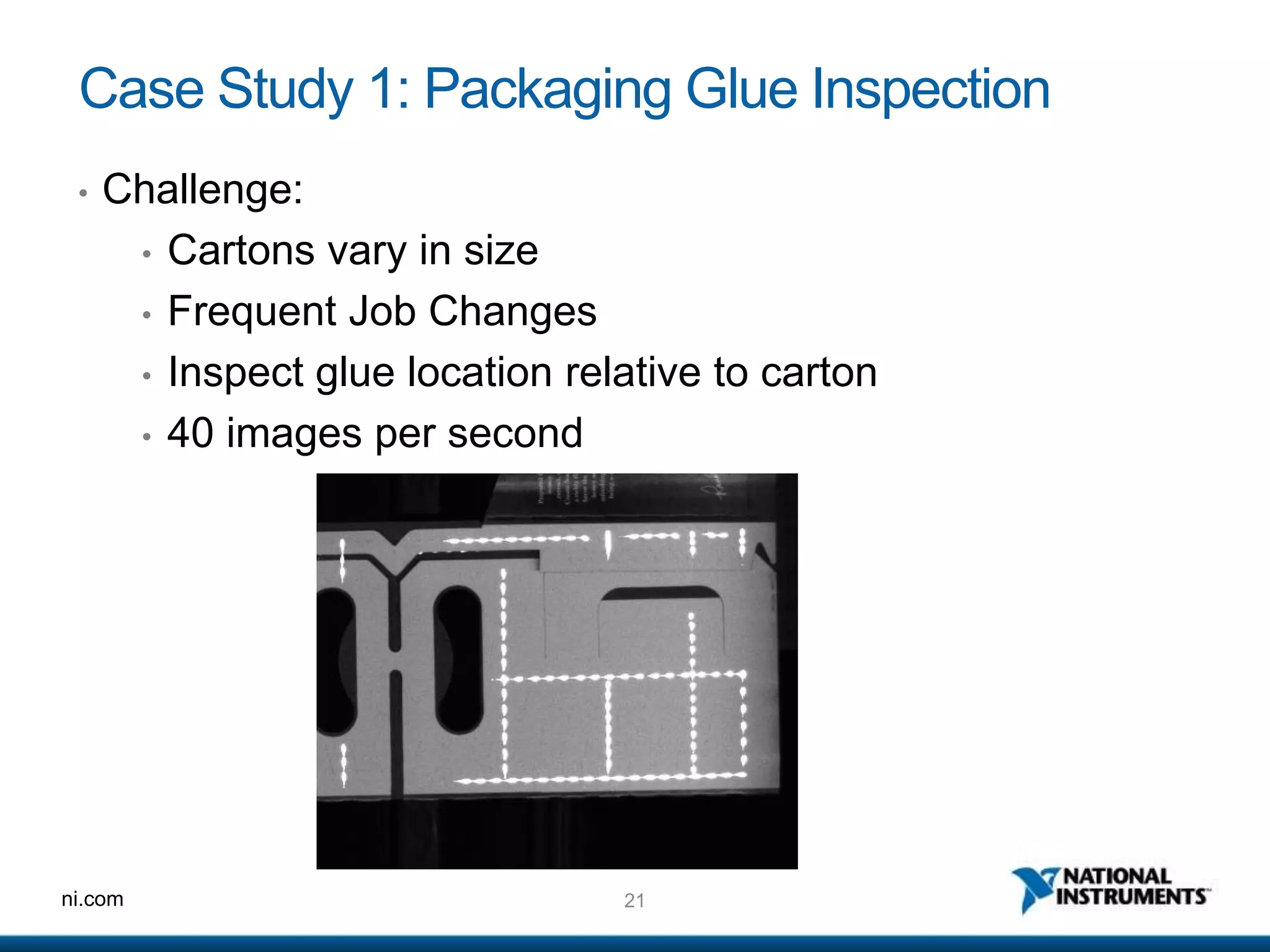

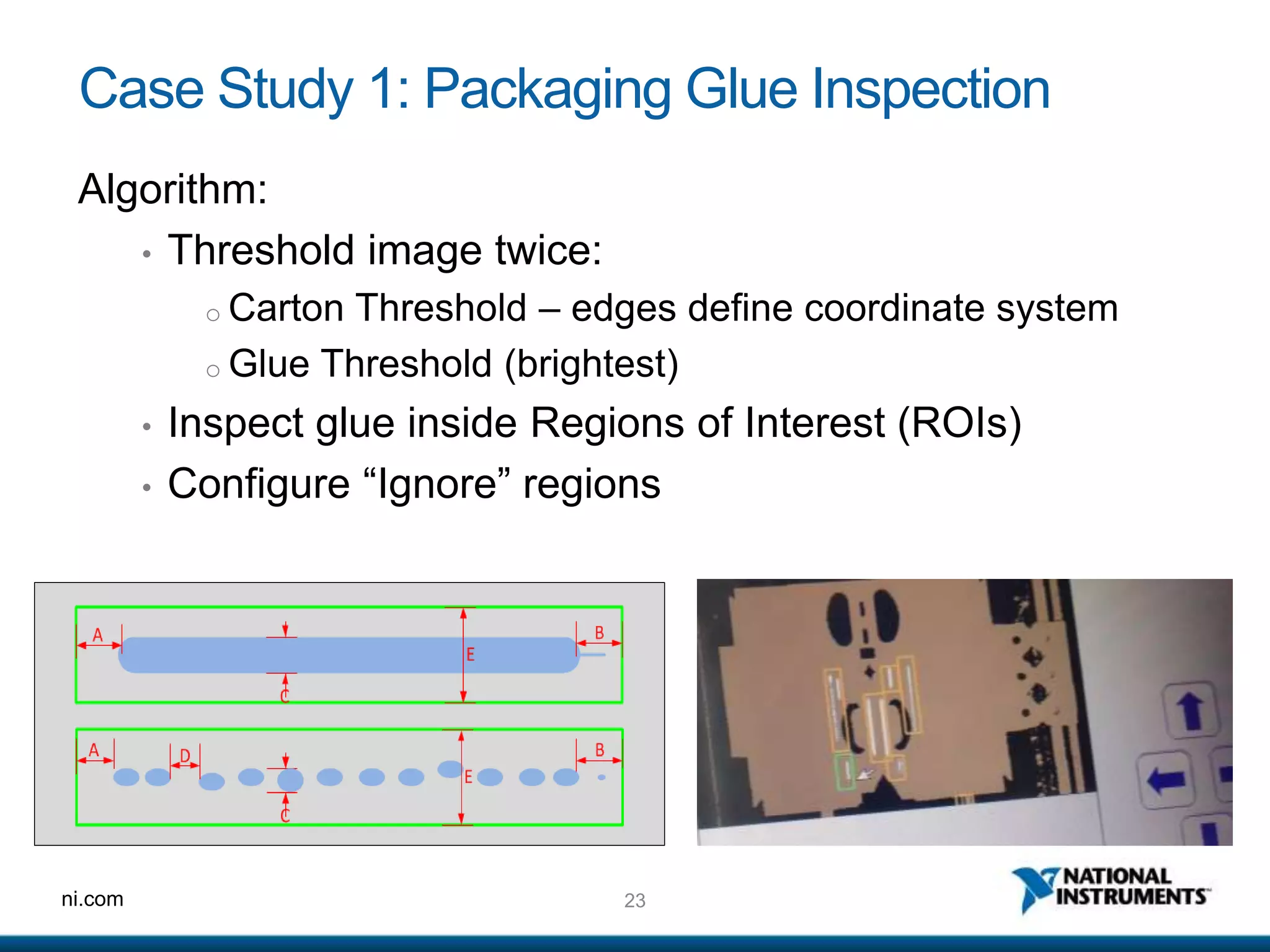

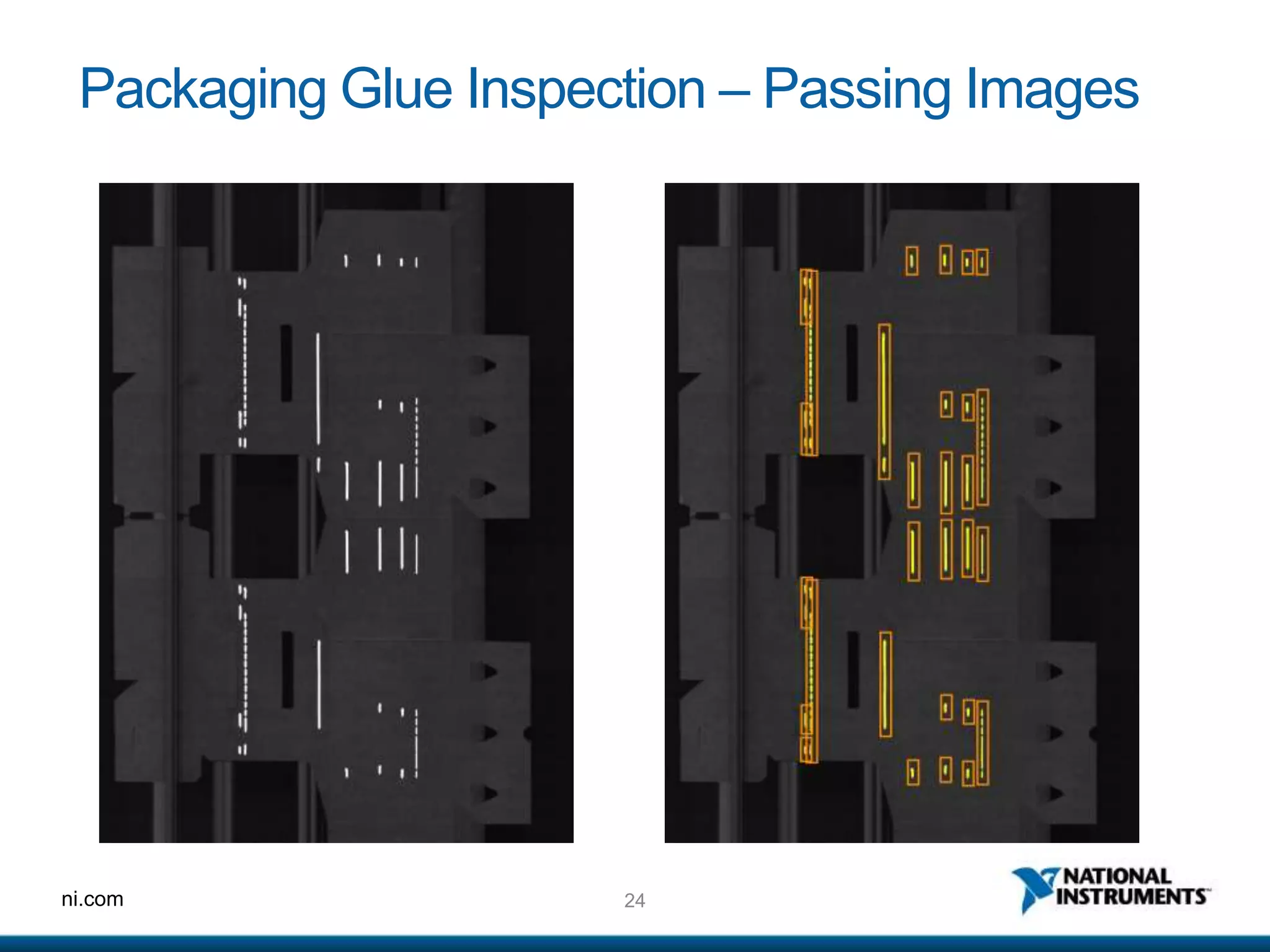

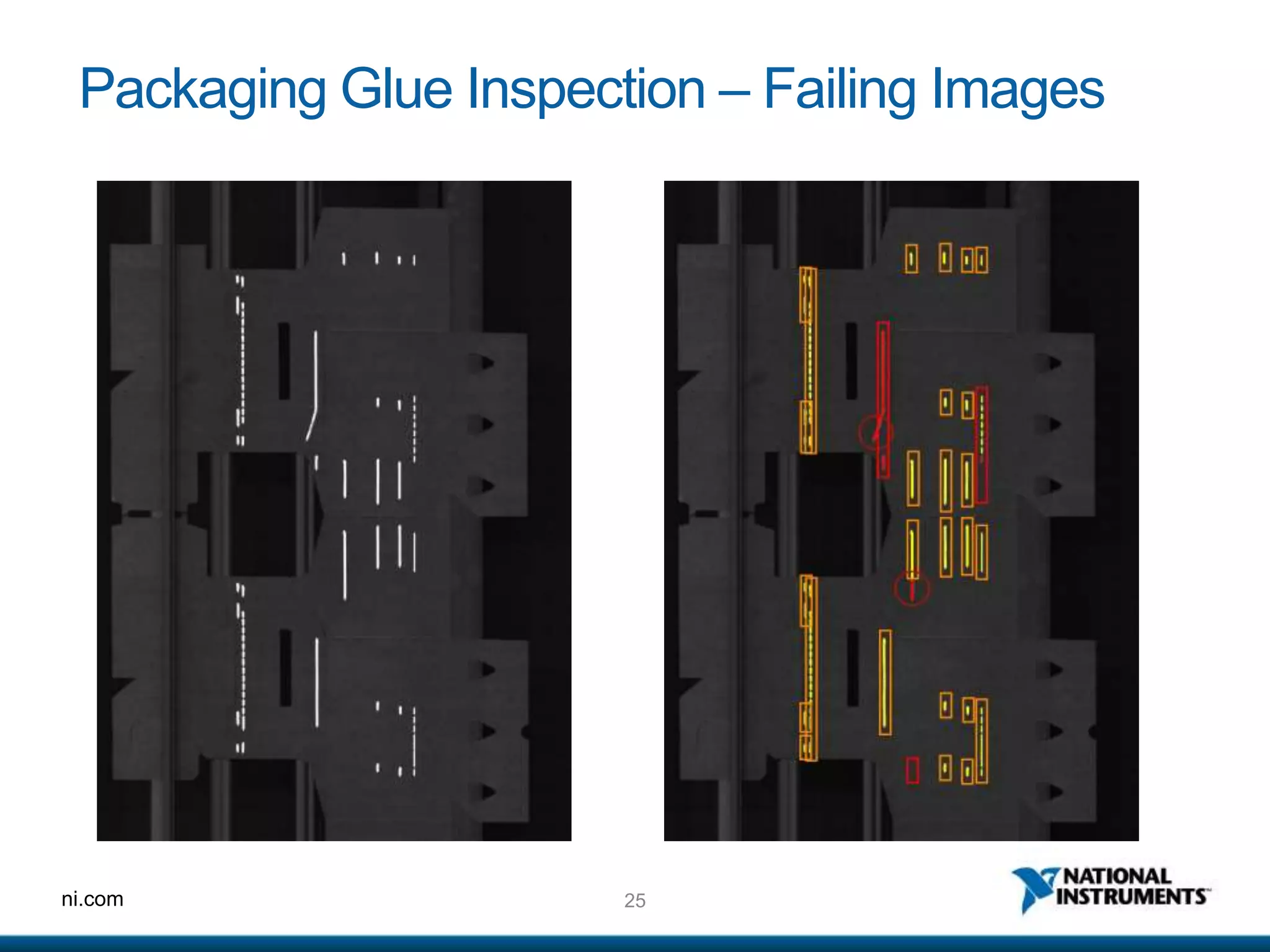

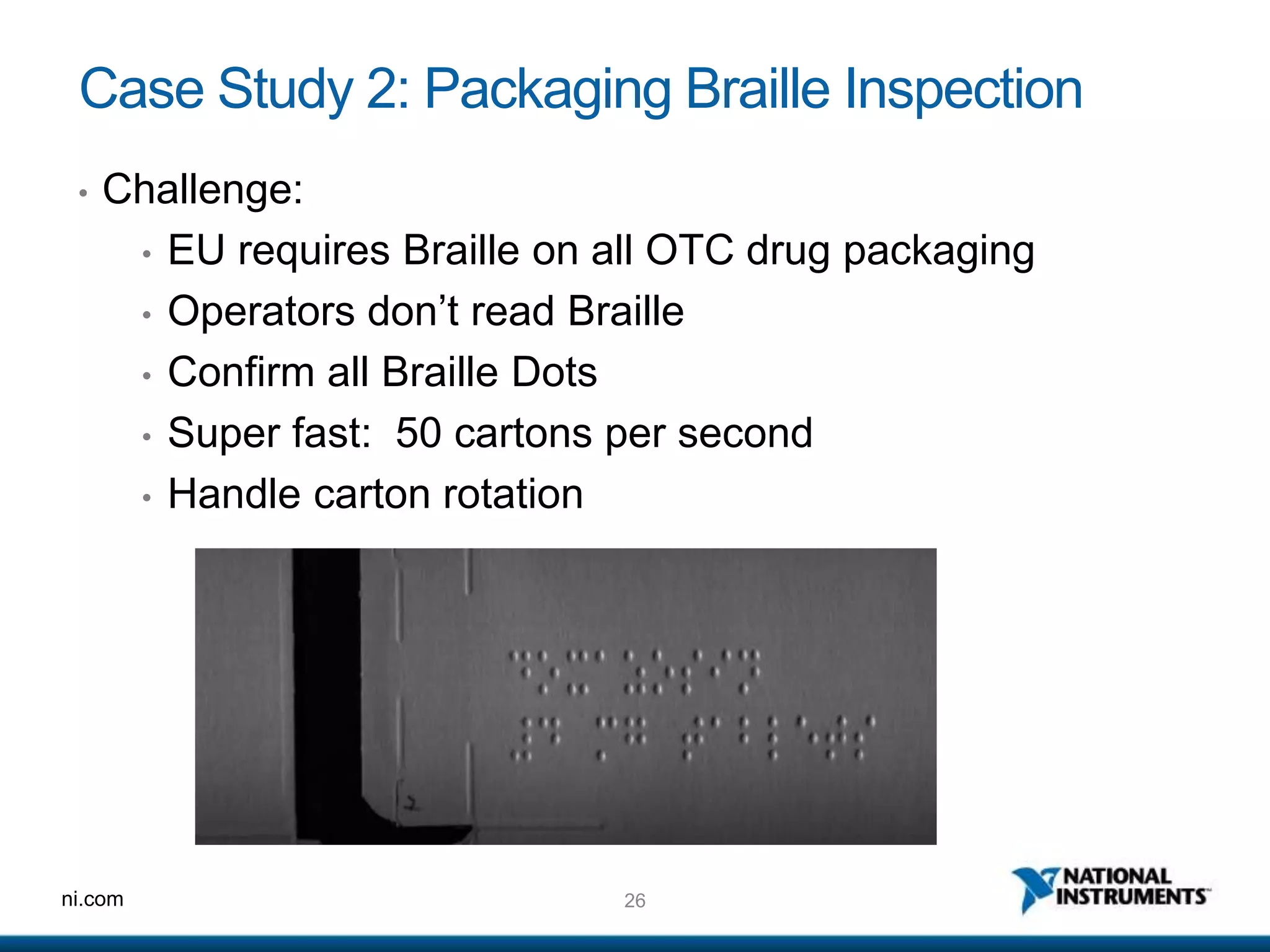

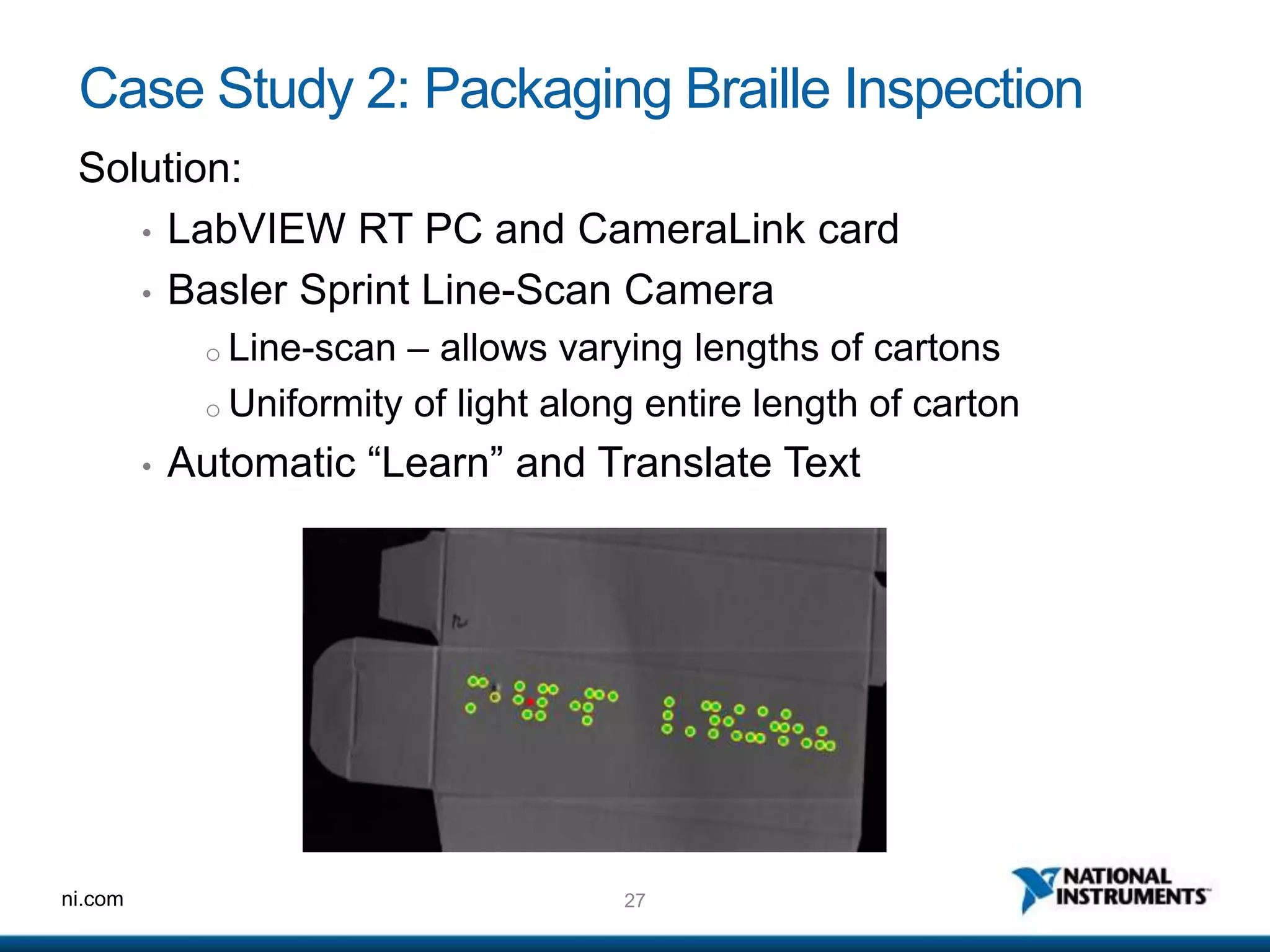

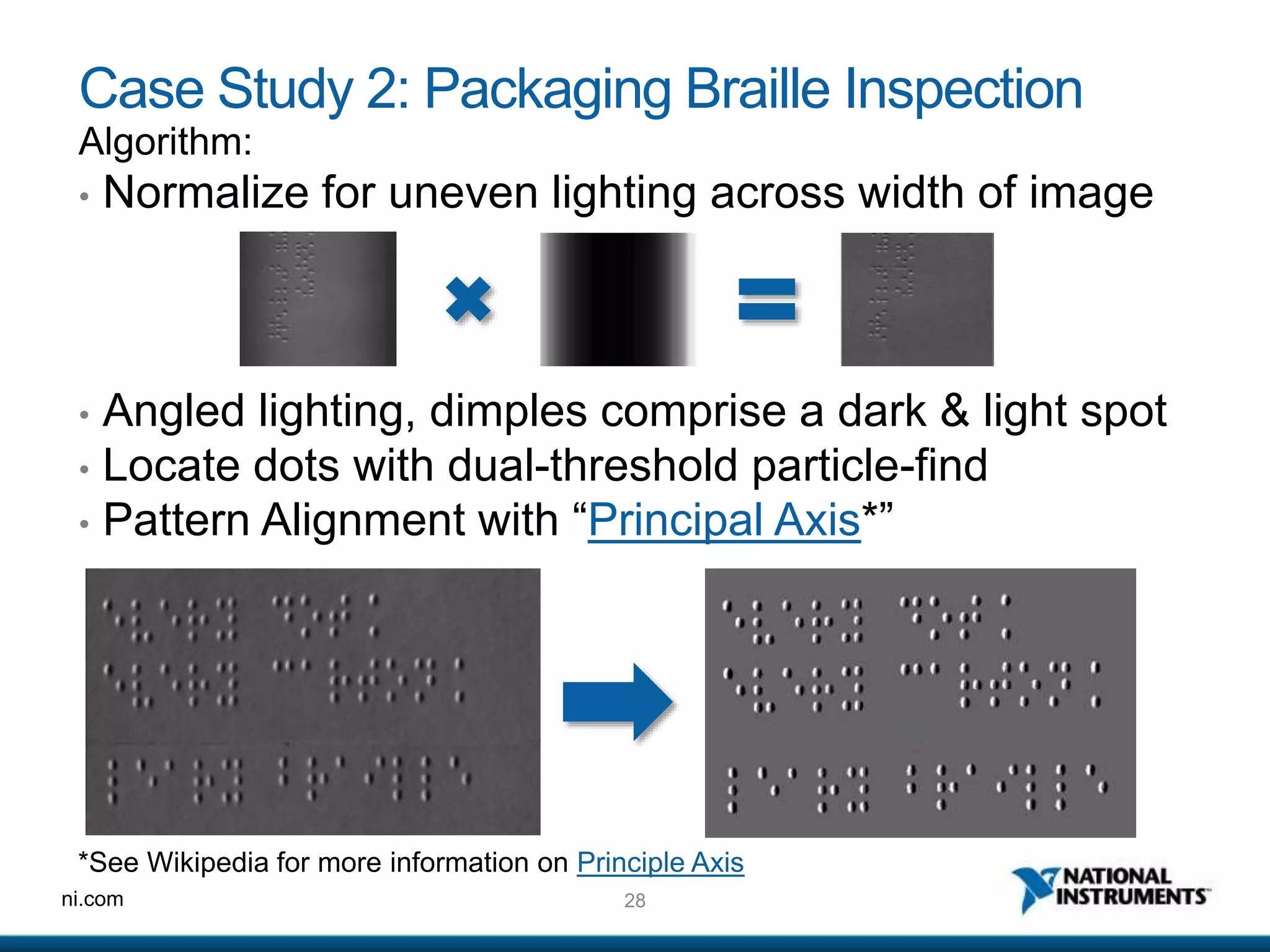

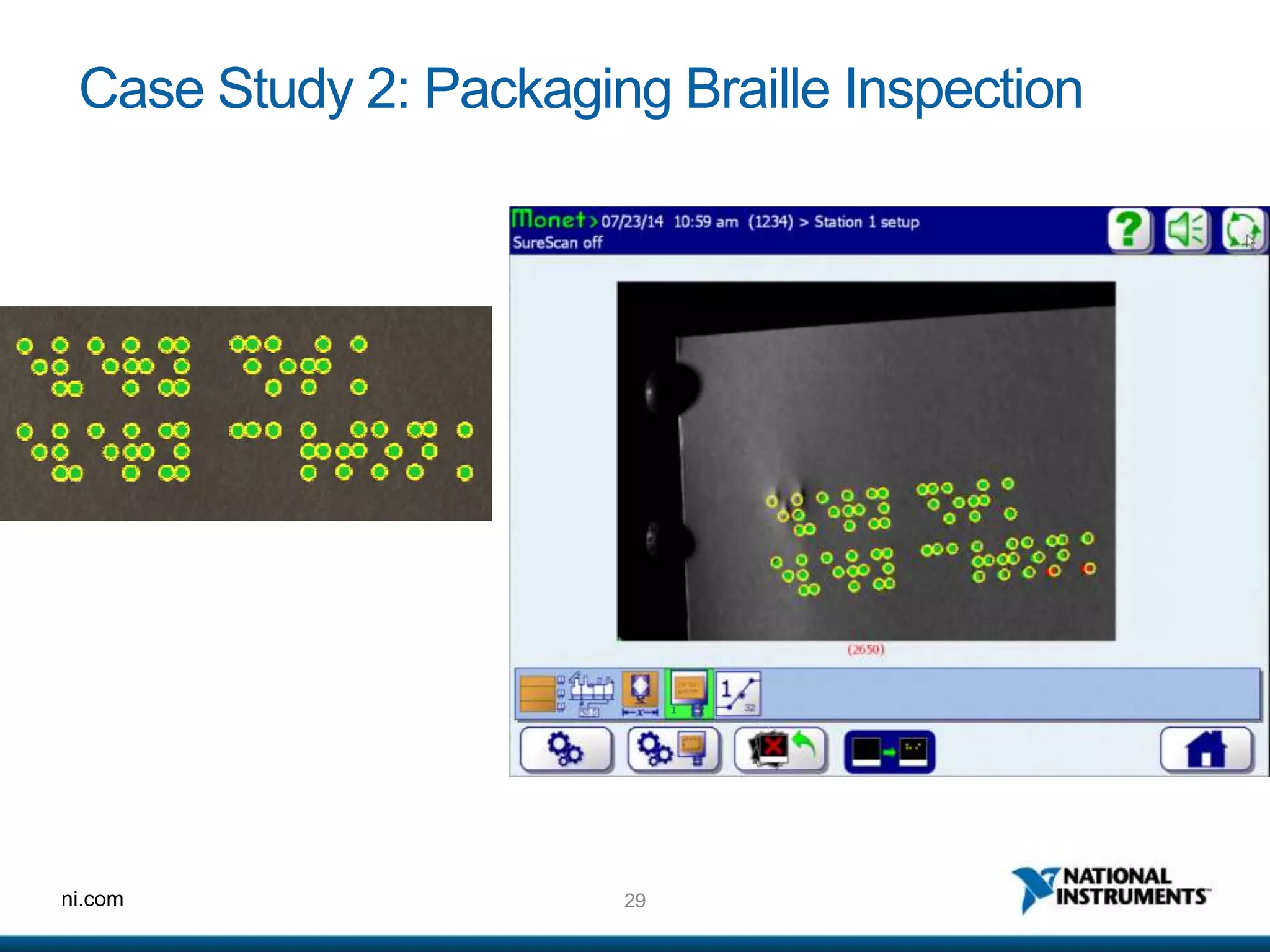

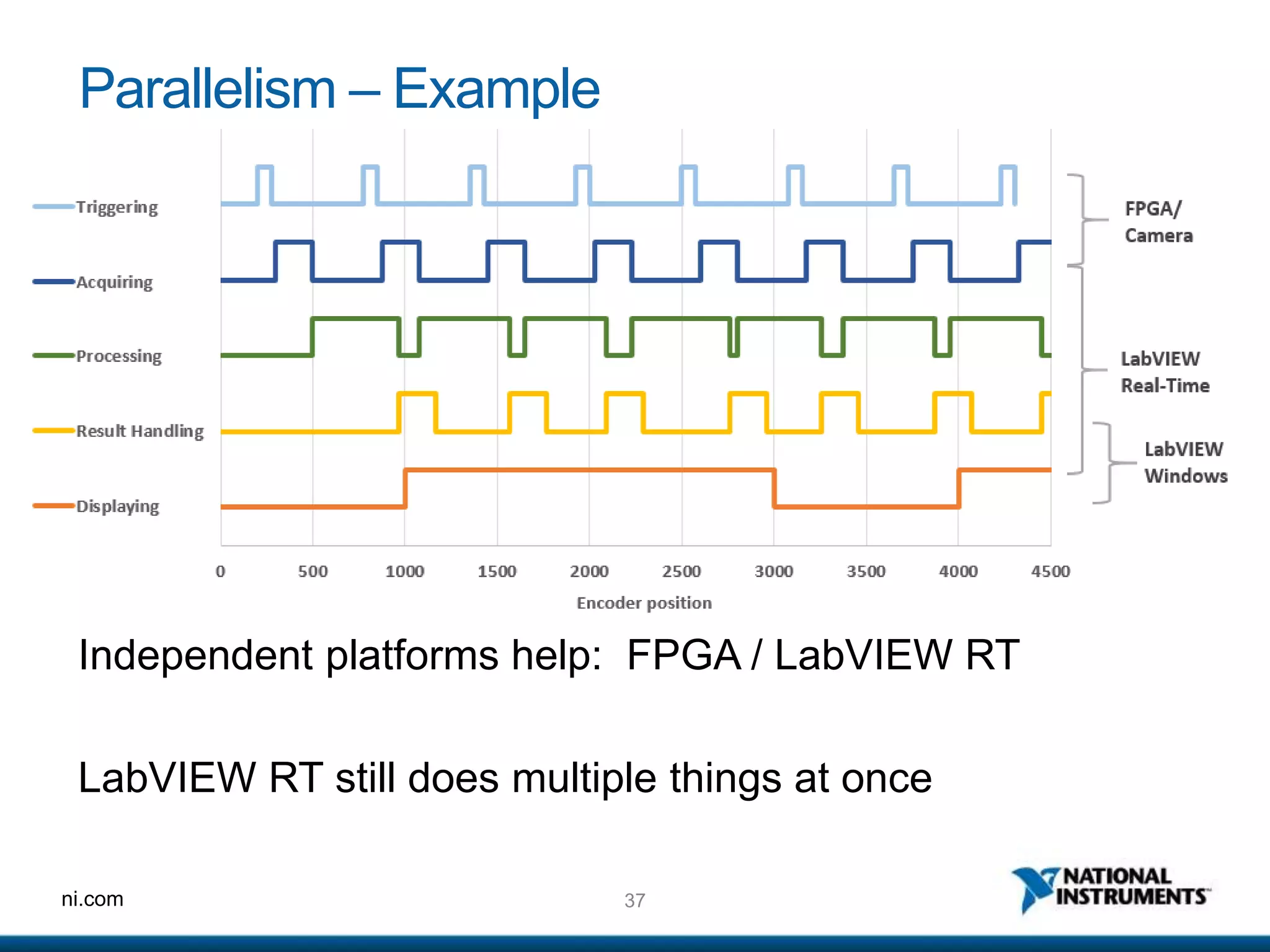

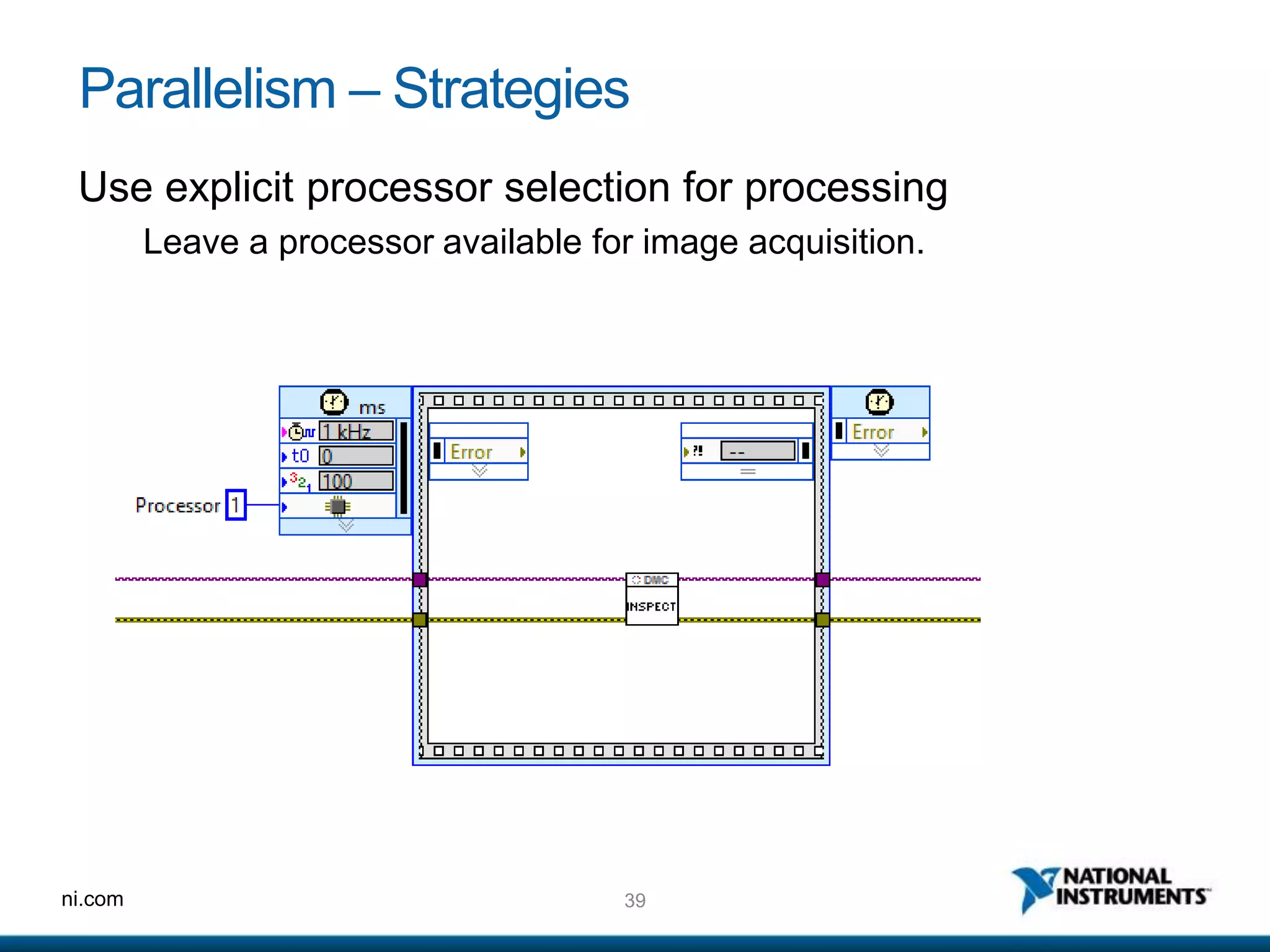

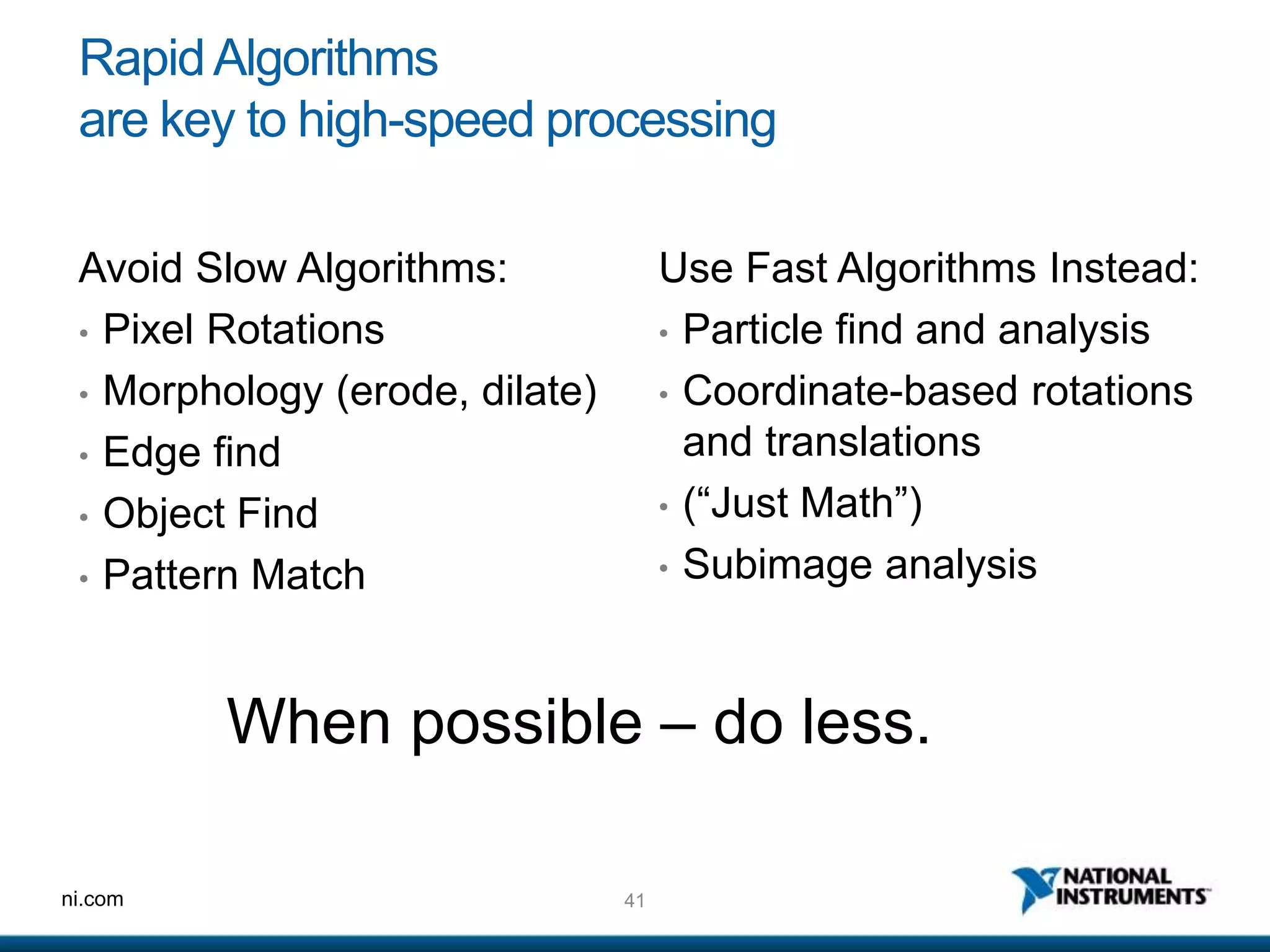

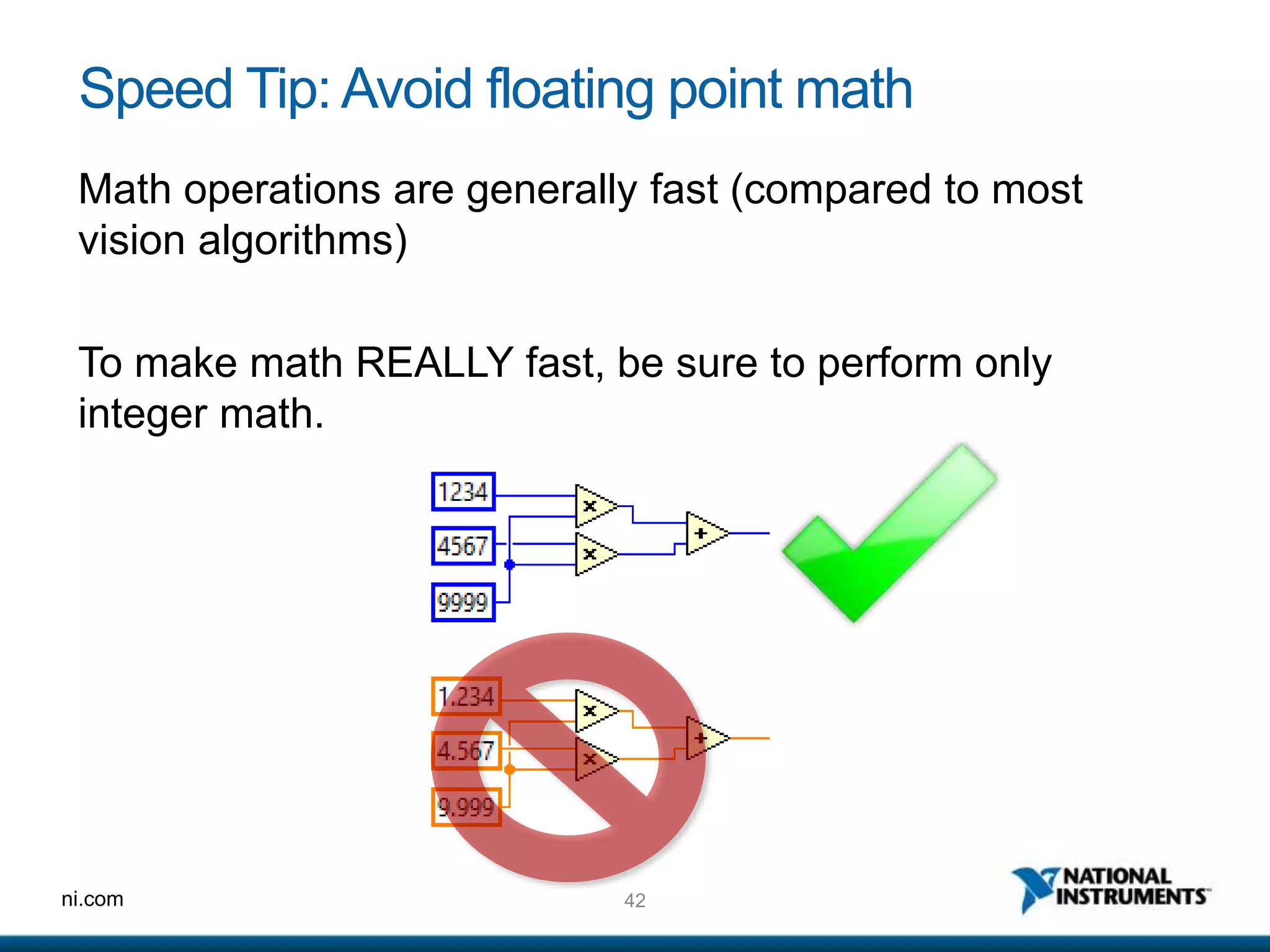

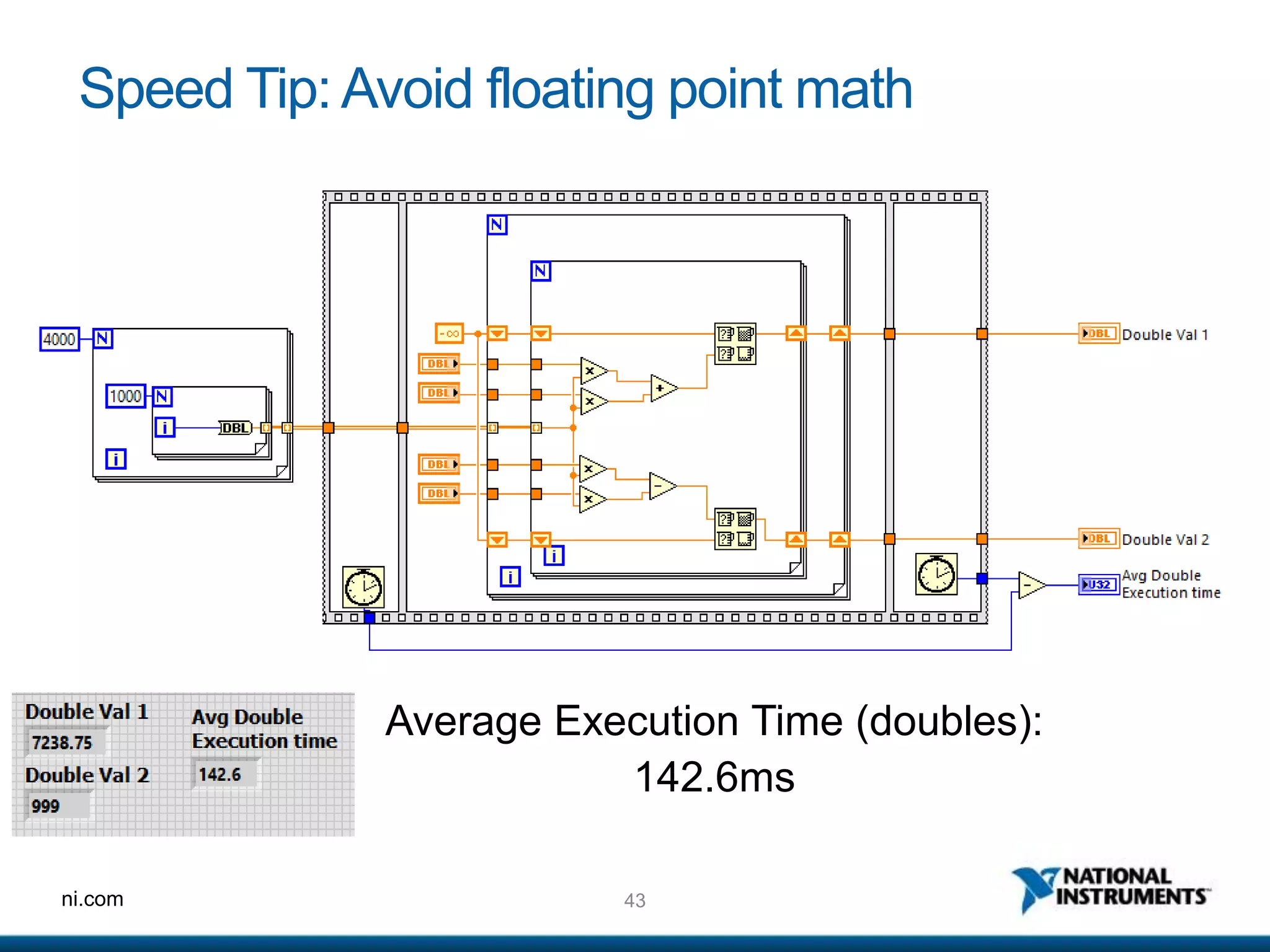

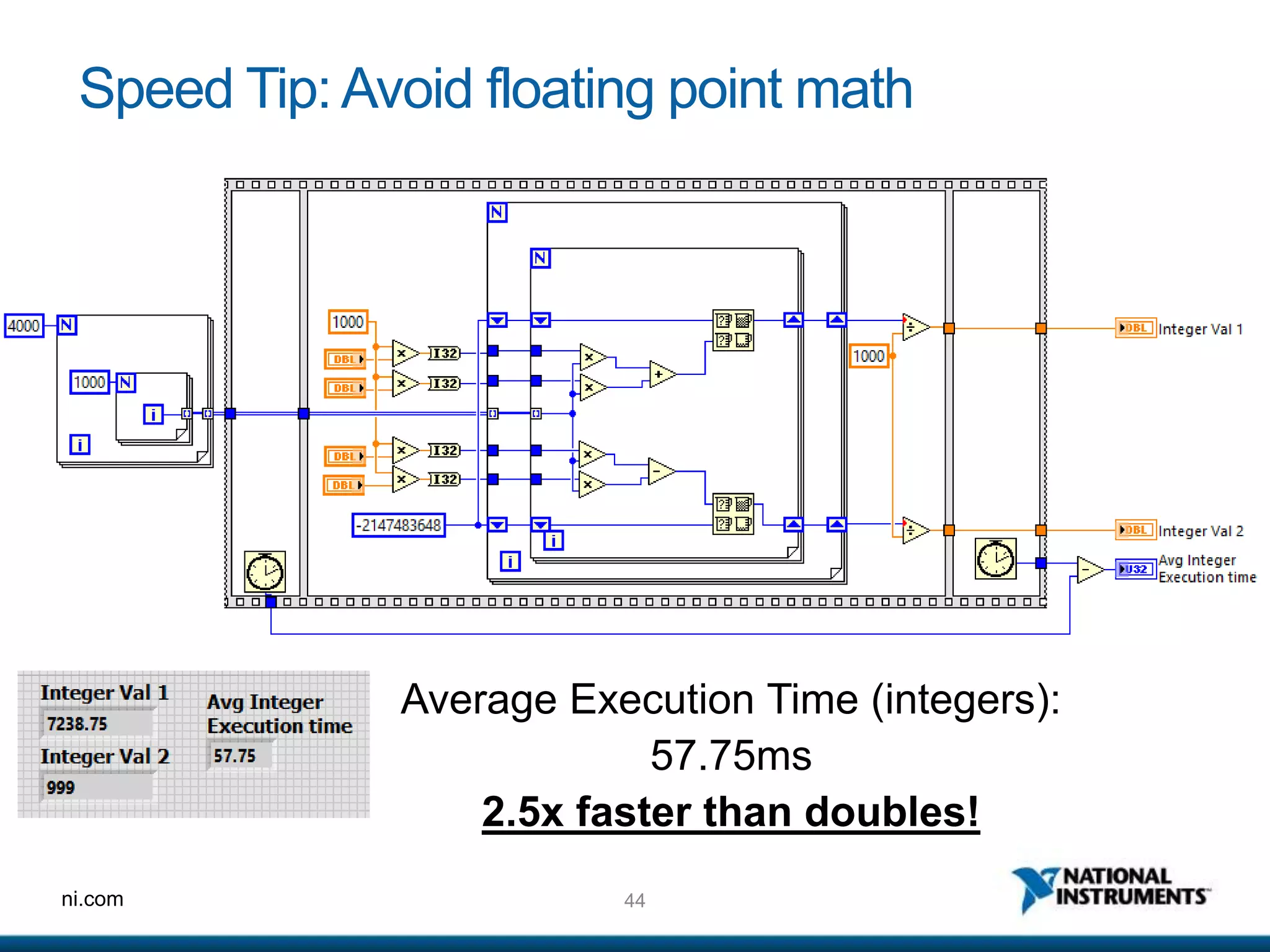

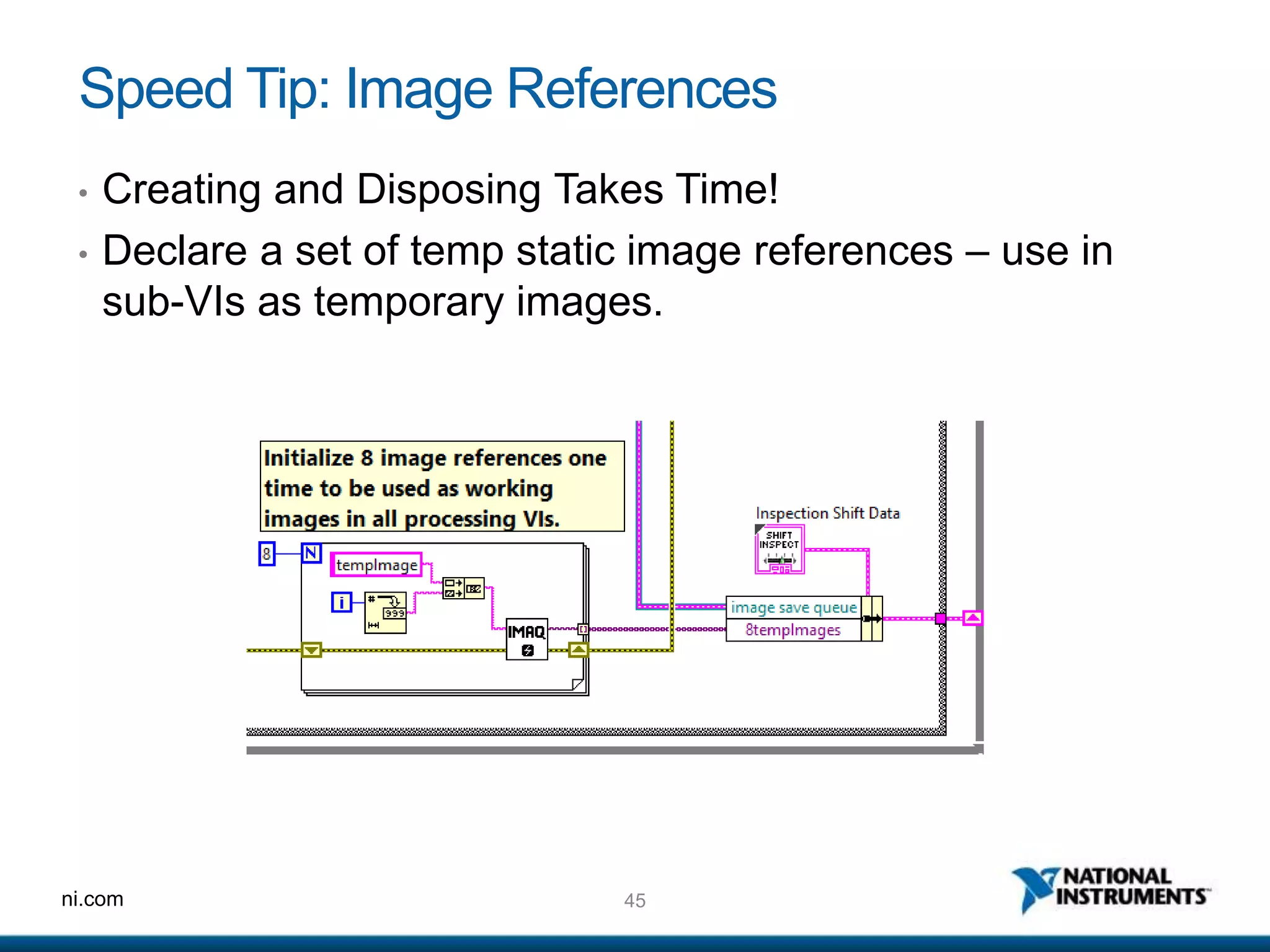

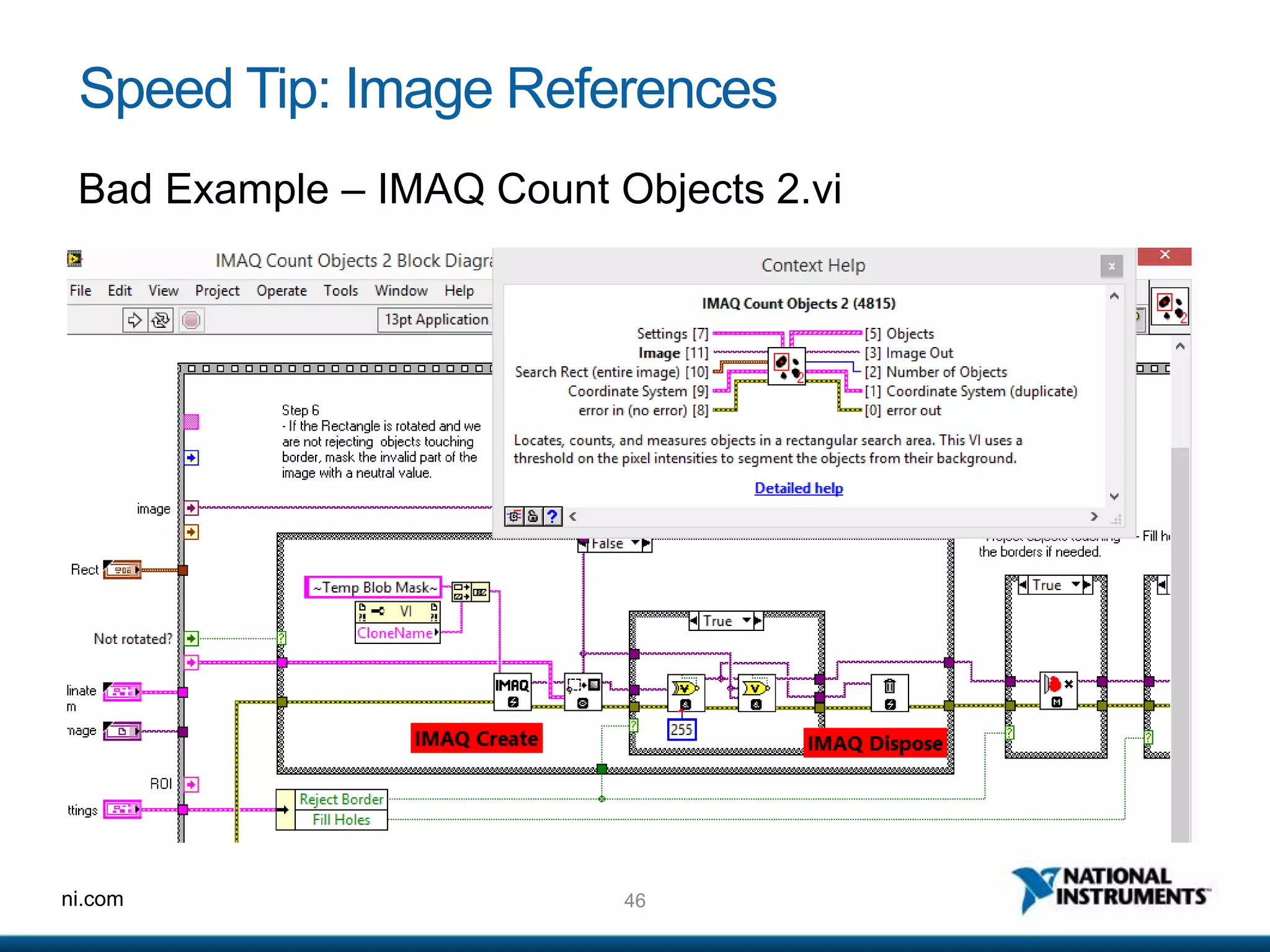

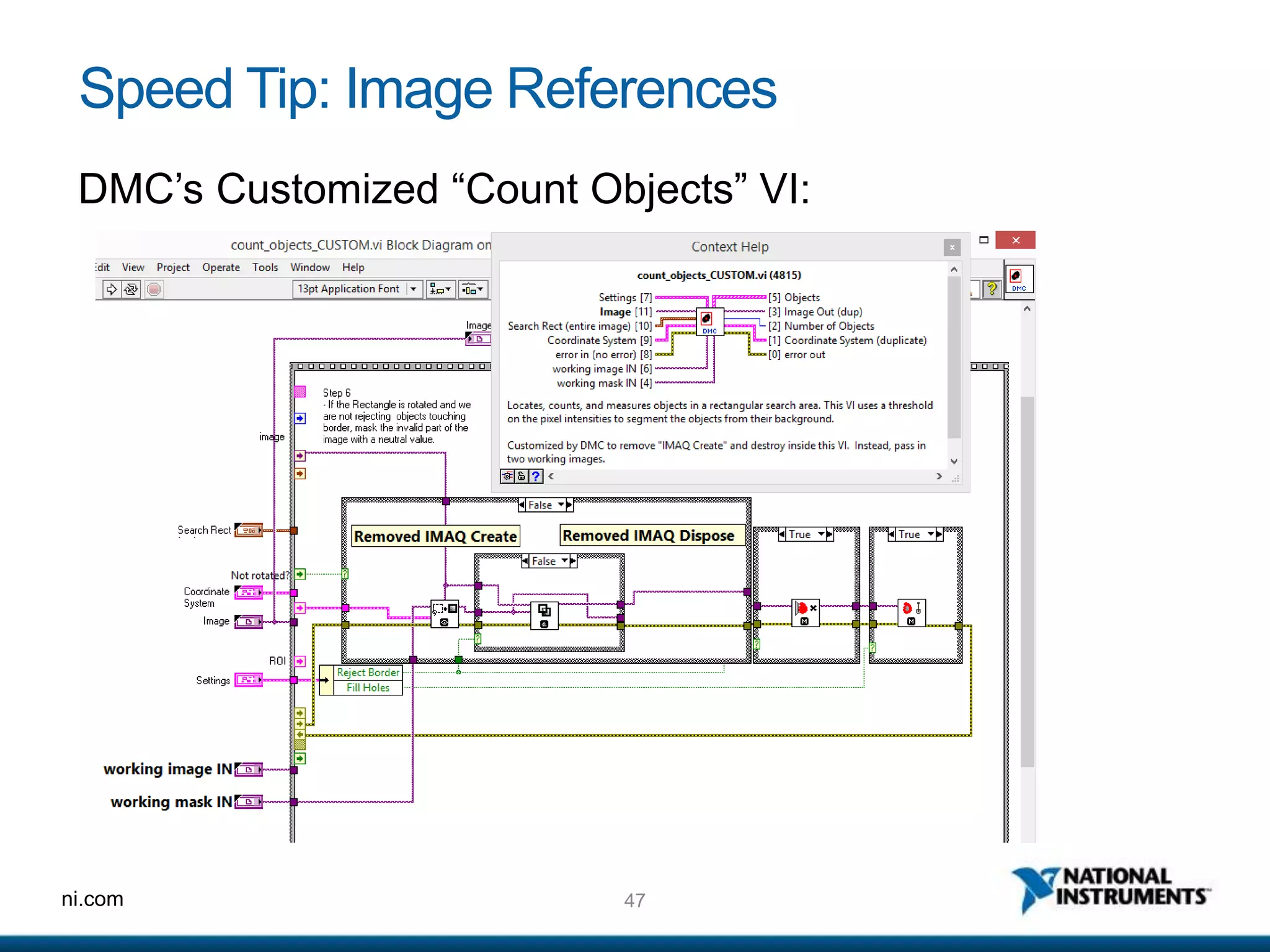

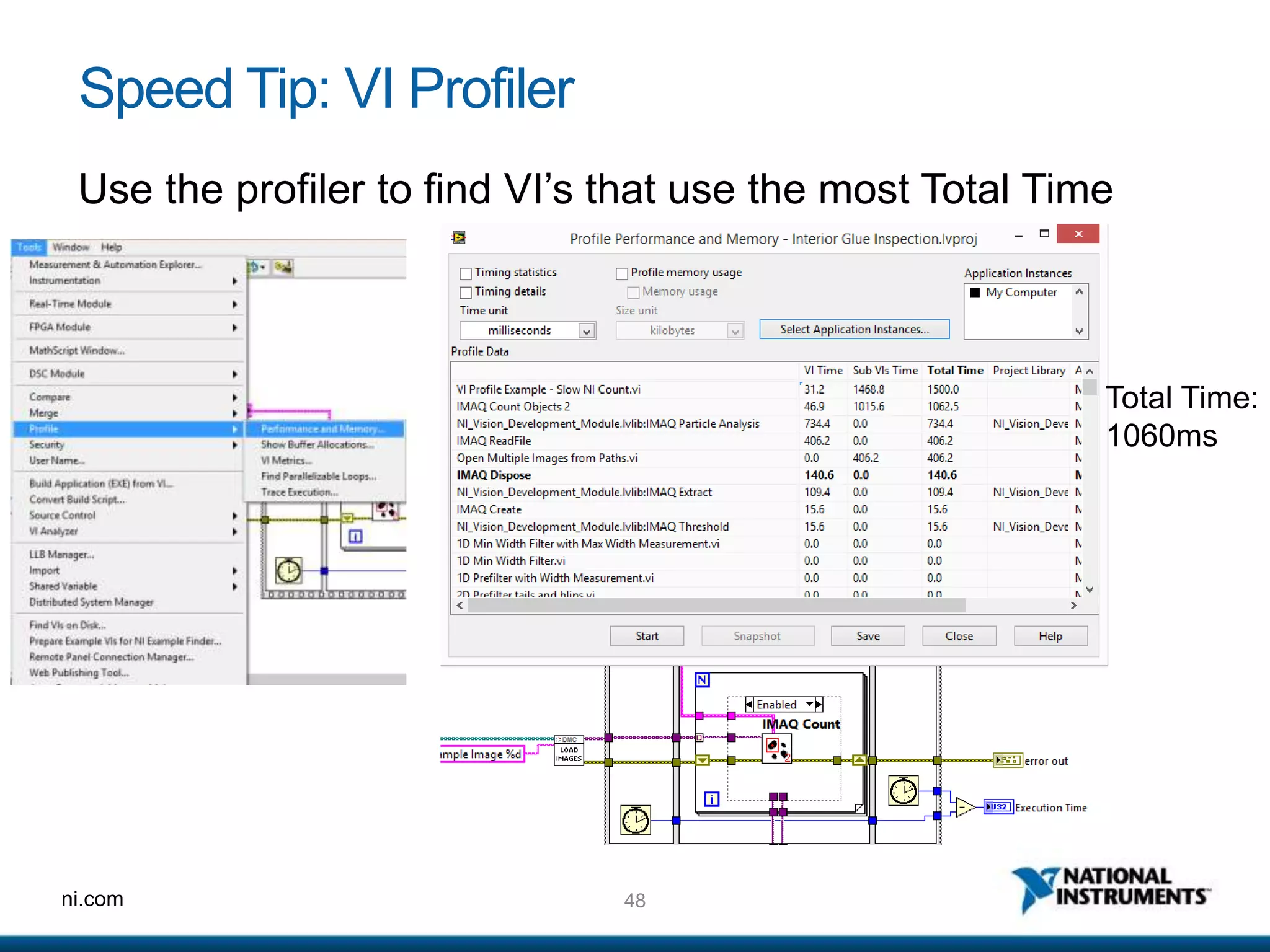

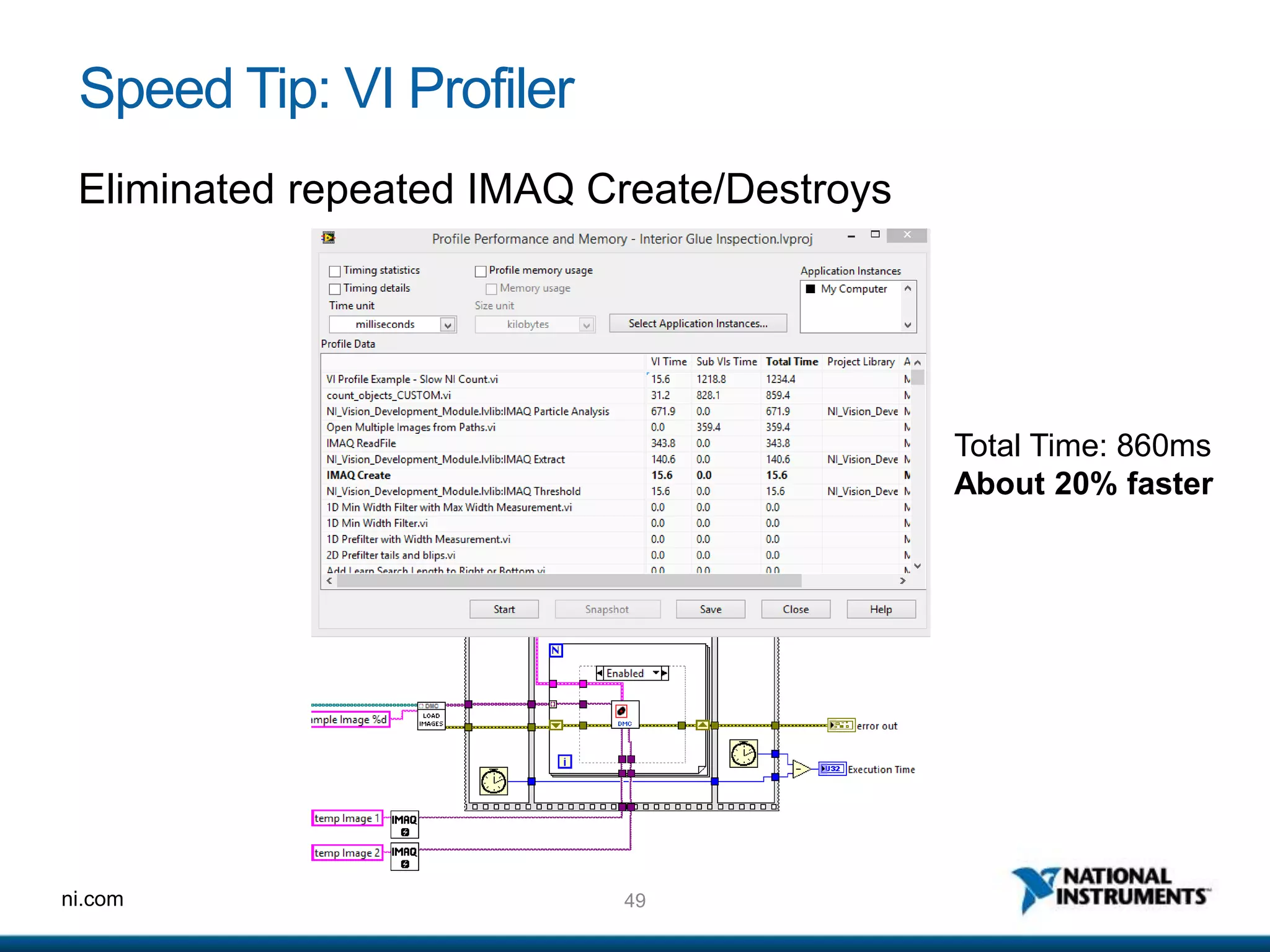

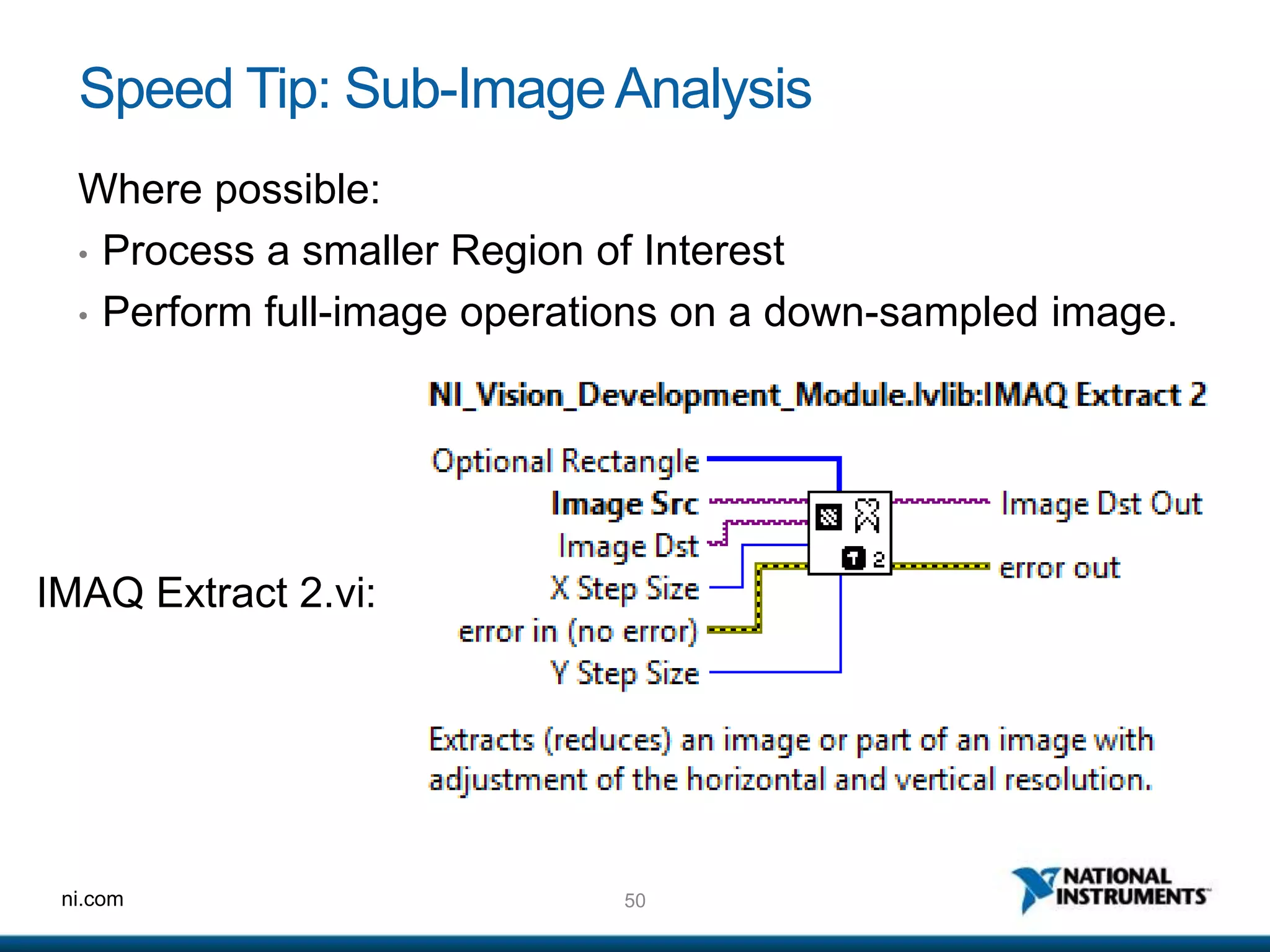

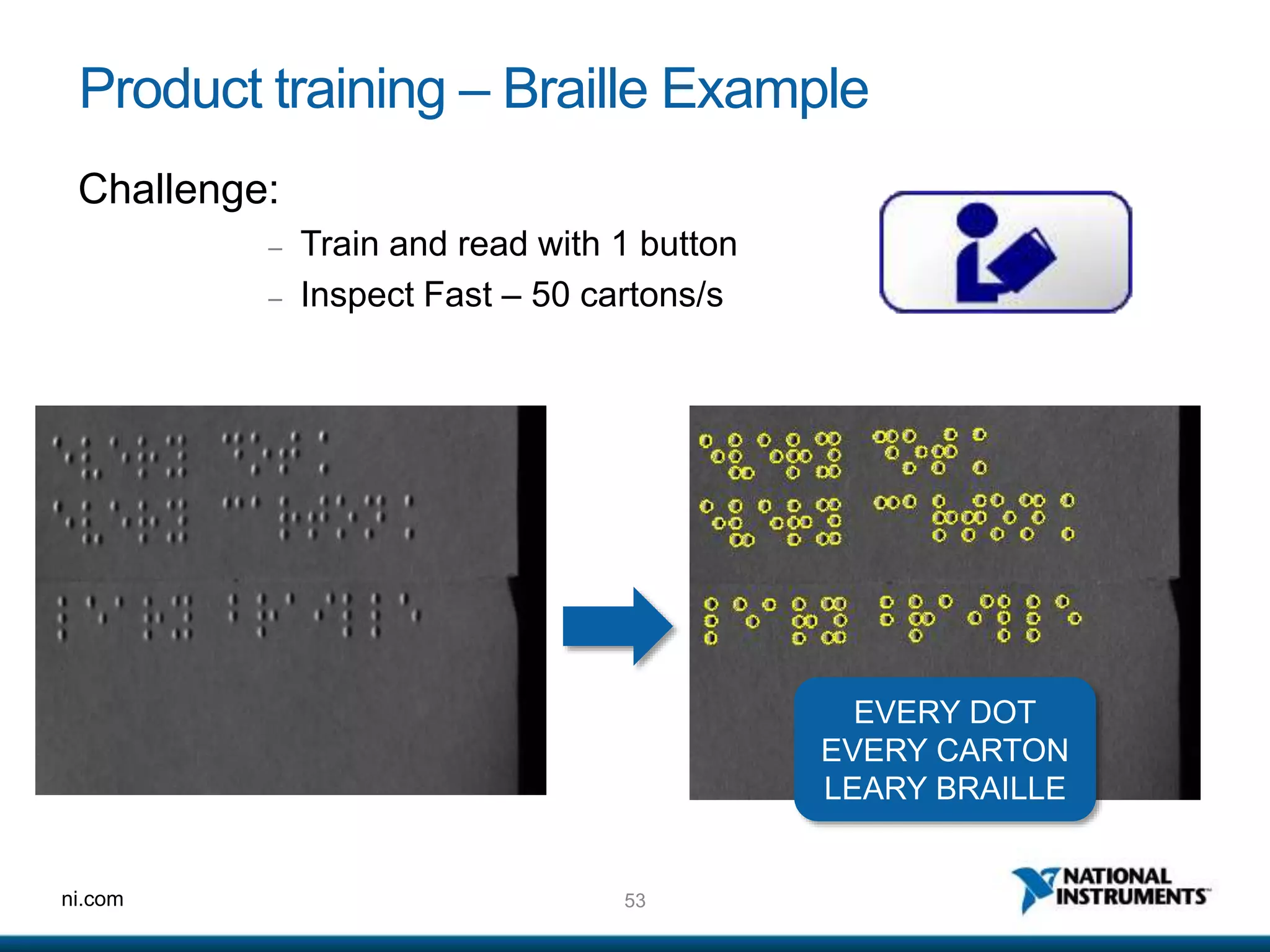

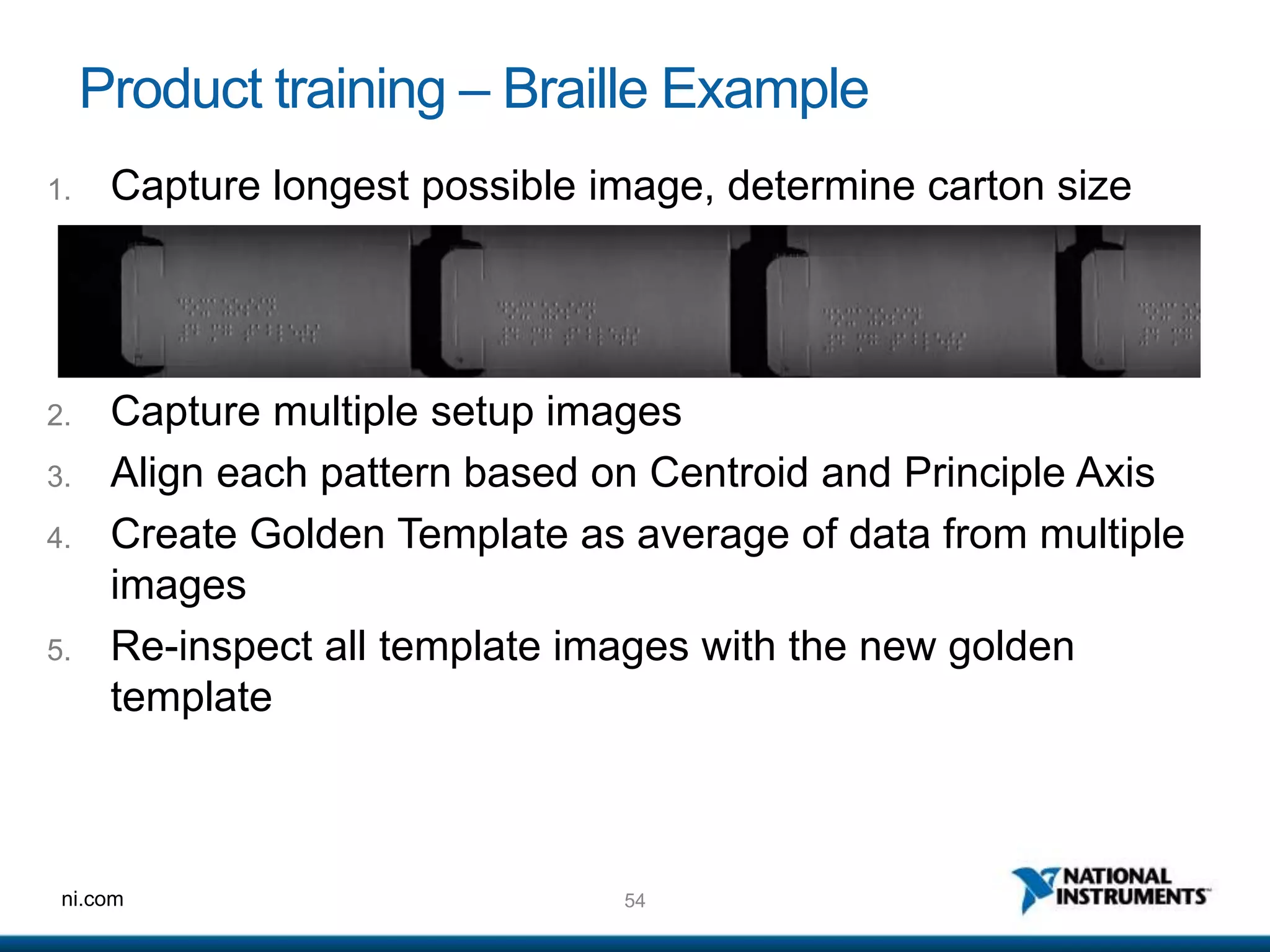

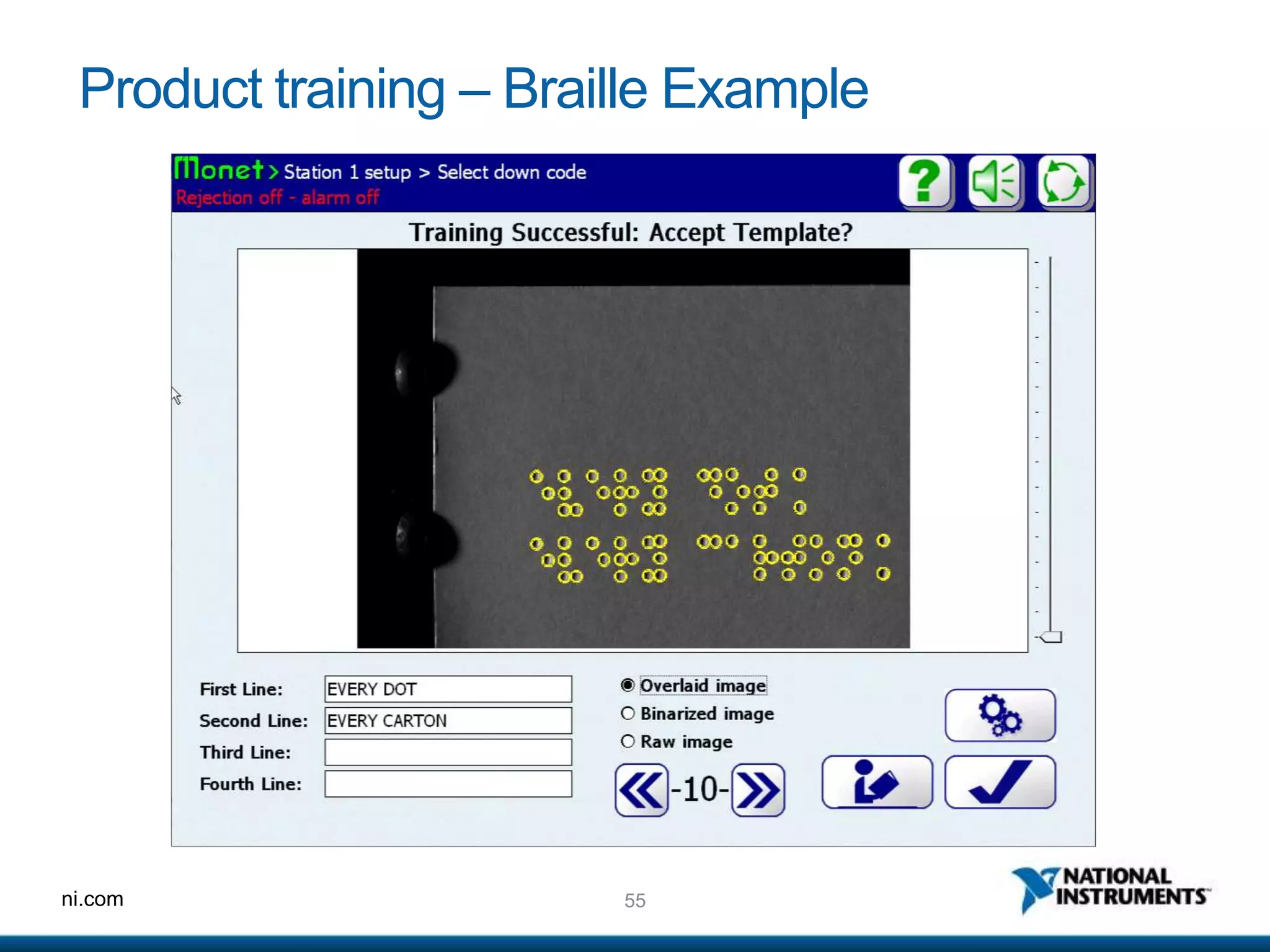

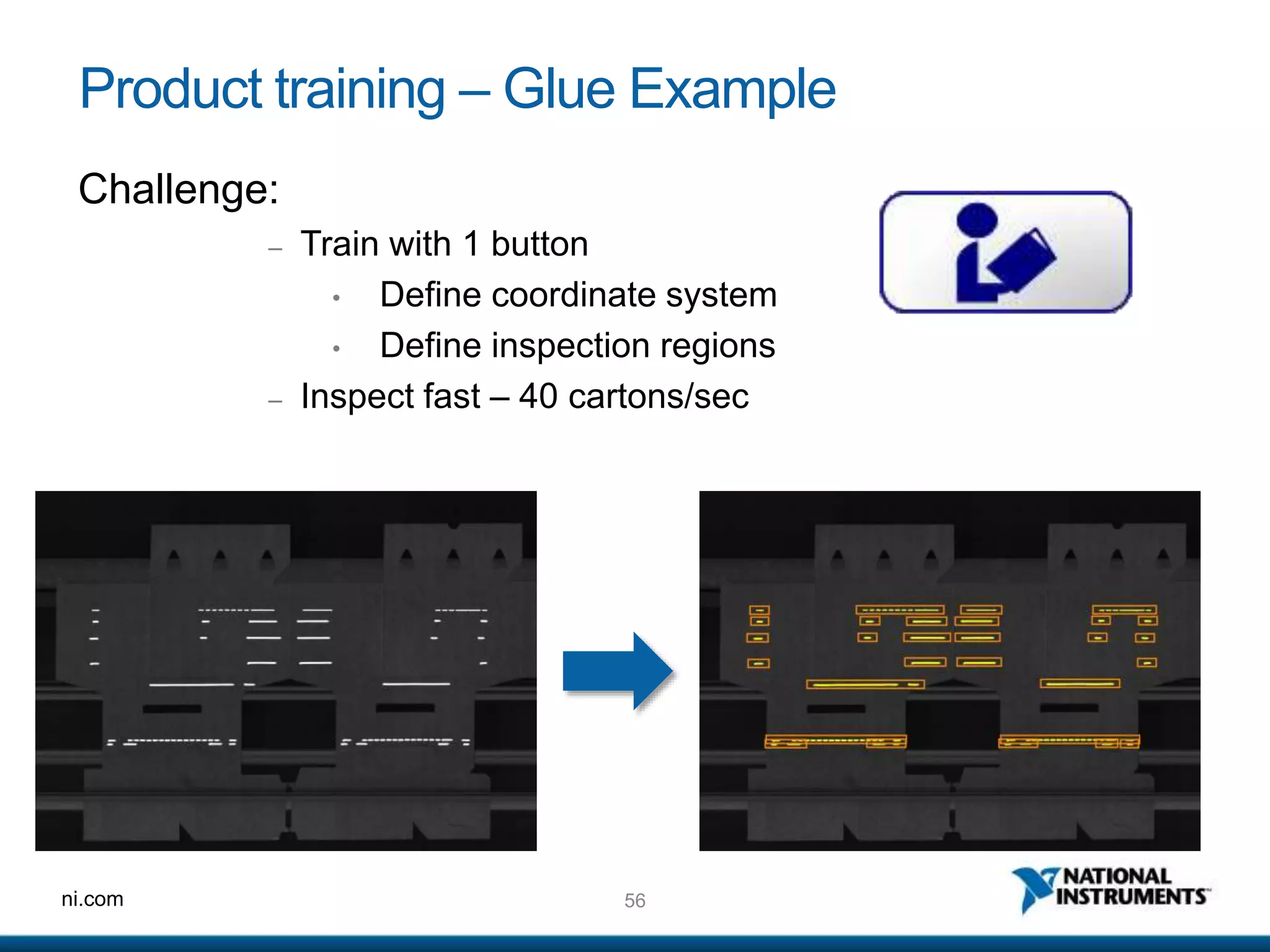

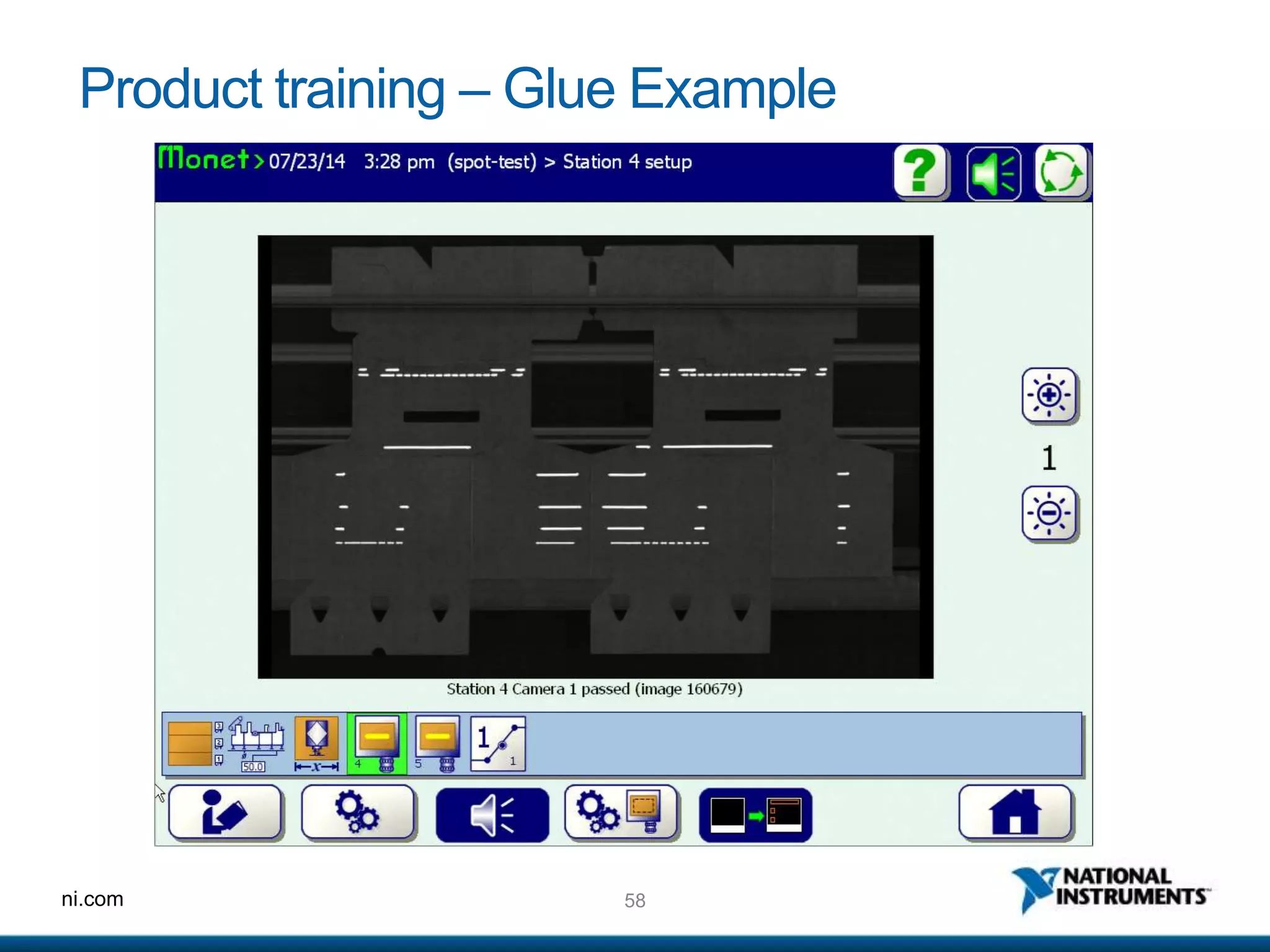

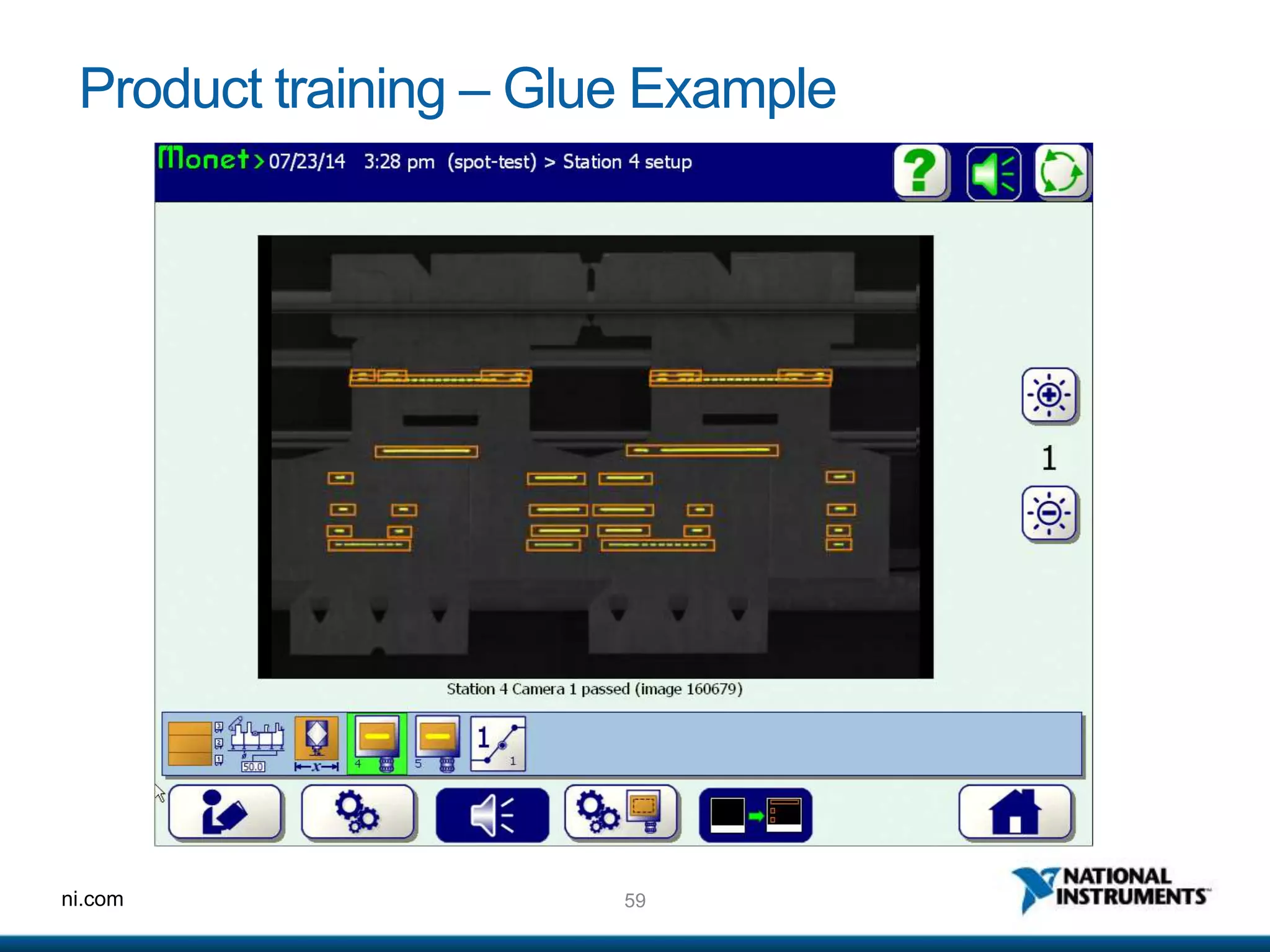

The document outlines a presentation on high-speed vision inspection techniques, led by DMC Inc. presenters Kenneth Brey and Eric West, discussing various hardware architectures, customer-focused case studies, and algorithmic strategies for real-time image processing. Key topics include definitions of high-speed vision, hardware options like windows PC-based solutions and smart cameras, and rapid algorithm tips that enhance processing efficiency. The emphasis is on delivering high-speed inspection solutions across multiple industries, ensuring zero defects, and meeting customer demands for complexity and speed.