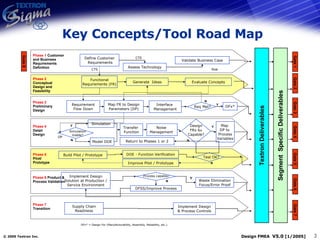

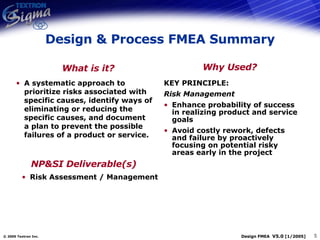

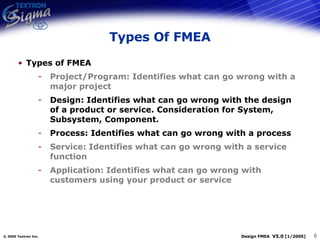

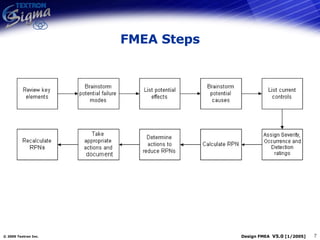

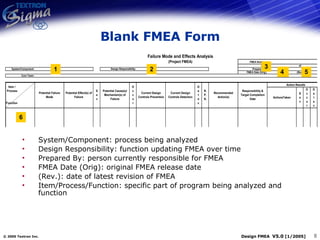

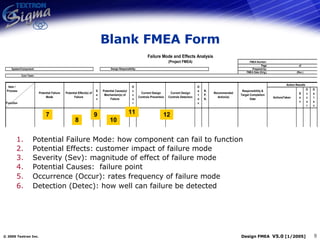

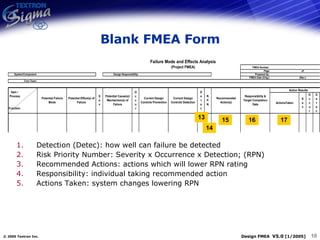

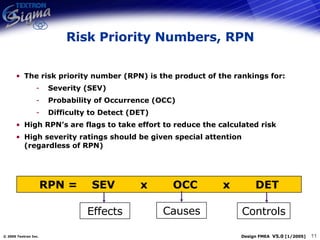

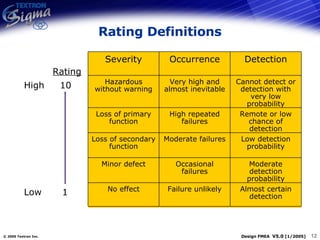

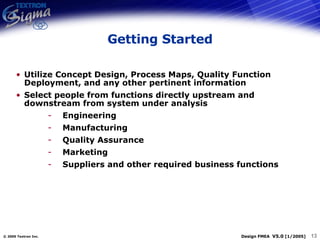

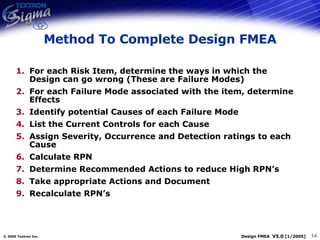

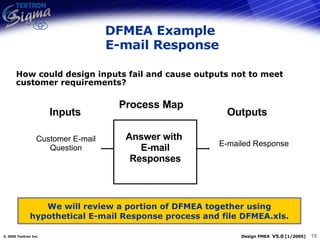

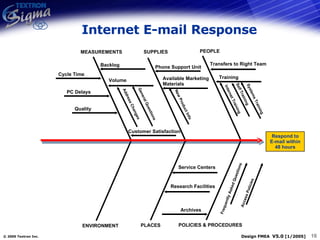

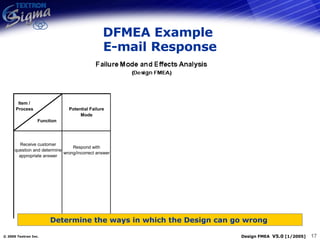

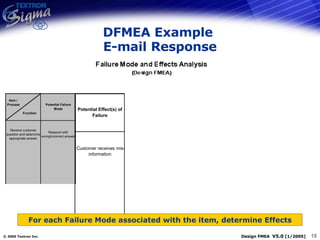

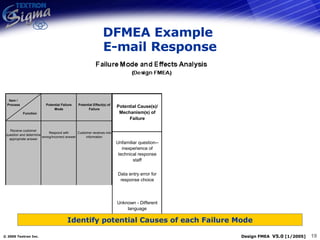

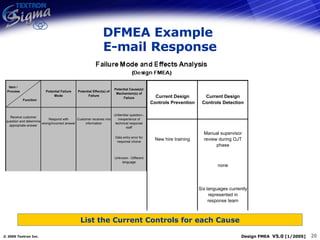

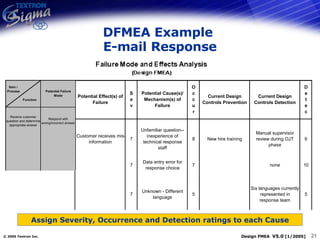

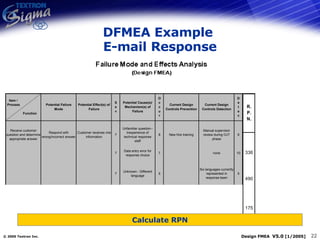

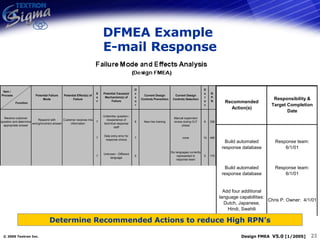

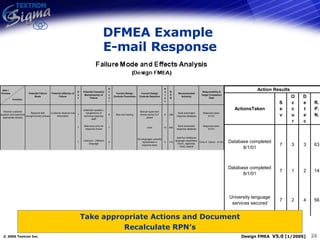

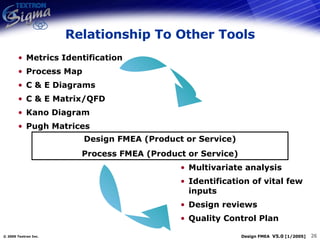

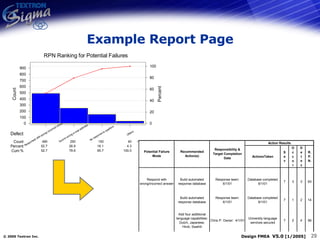

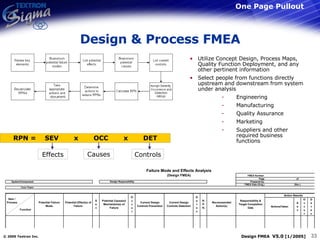

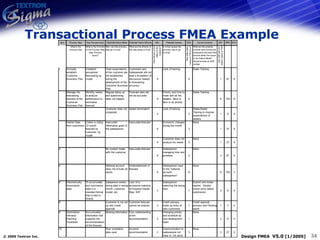

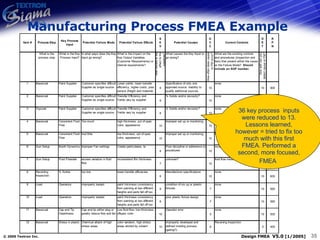

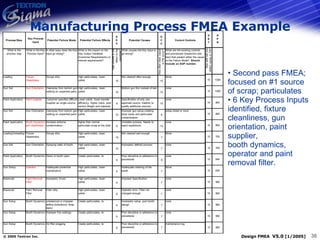

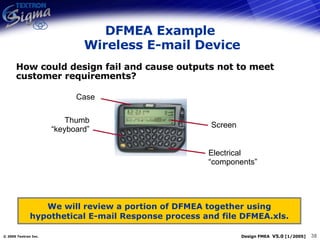

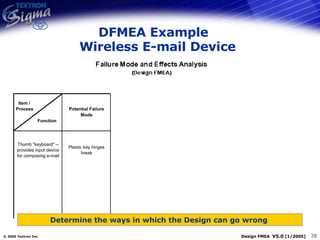

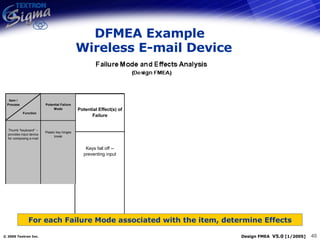

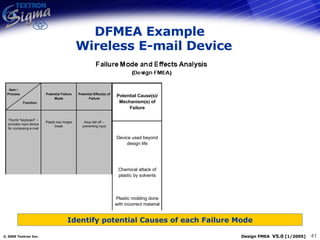

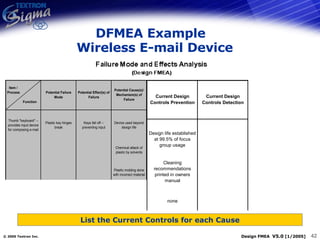

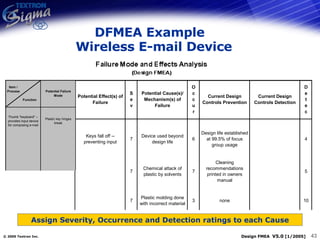

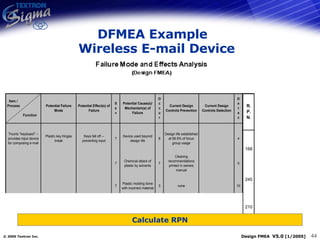

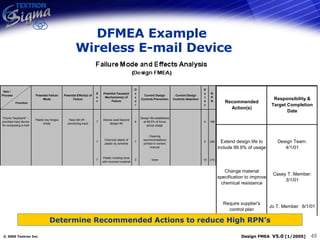

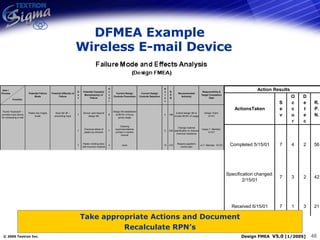

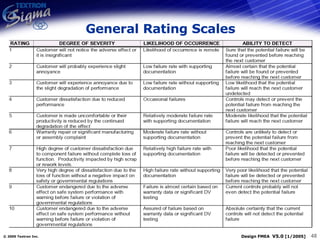

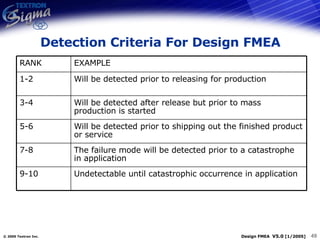

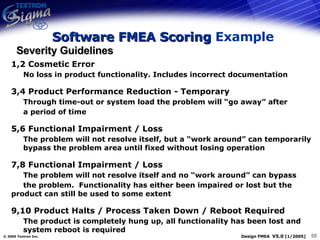

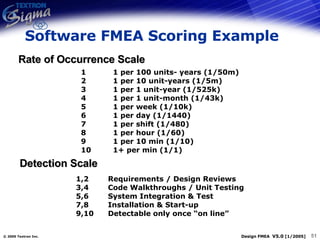

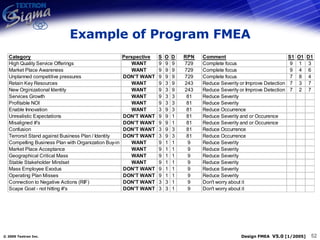

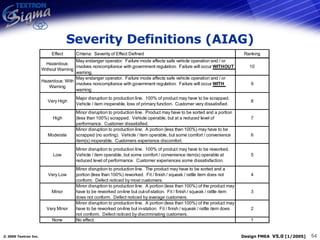

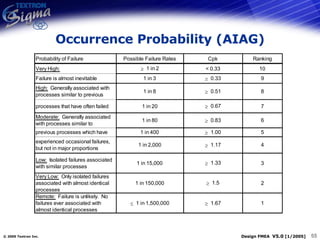

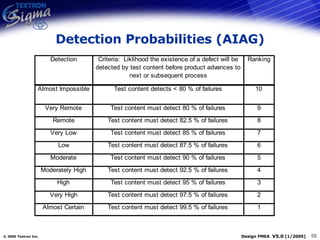

This document provides an overview of Failure Mode and Effects Analysis (FMEA) as a tool for analyzing and managing risks in product design and processes. It discusses how FMEA is used to systematically prioritize risks, identify ways to reduce causes of failure, and document prevention plans. The key steps of an FMEA include determining potential failure modes and their effects, identifying causes, assessing current controls, and calculating risk priorities to inform action planning. FMEA should be conducted throughout the design process and involve cross-functional teams.