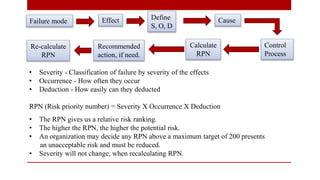

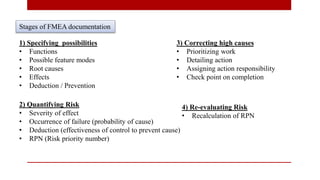

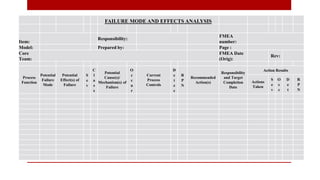

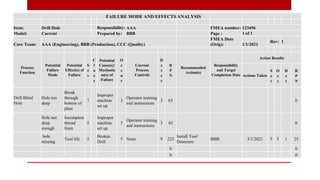

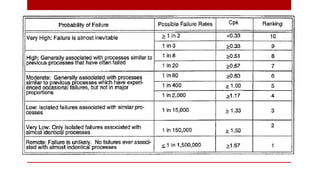

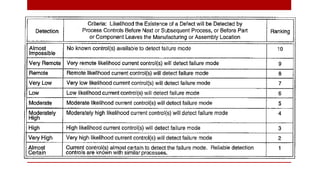

FMEA stands for Failure Mode and Effects Analysis, which is a technique used to analyze potential failures in a design, manufacturing, or service process. There are different types of FMEAs, including Design FMEA (DFMEA) which focuses on potential failure modes in a design, and Process FMEA (PFMEA) which focuses on failures that could affect customers. The FMEA process involves specifying possible failures, quantifying the risk level of each failure using a Risk Priority Number (RPN), taking corrective actions on high-risk failures, and re-evaluating the risk levels. FMEAs are used to prevent failures before they occur and improve quality, reliability, and safety.