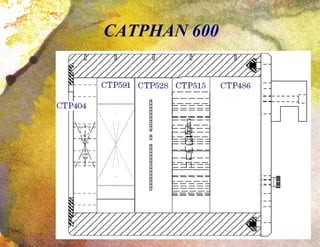

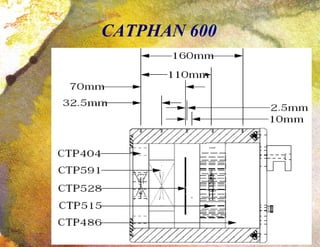

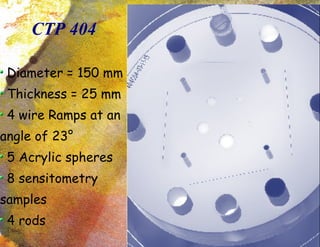

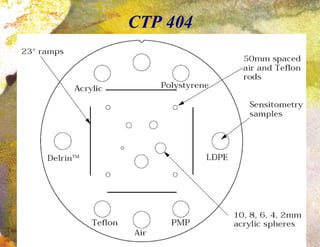

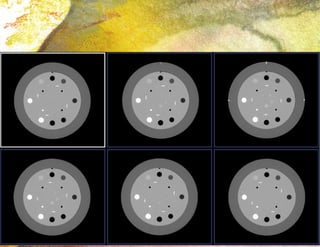

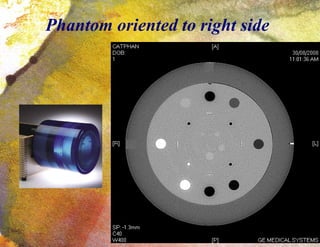

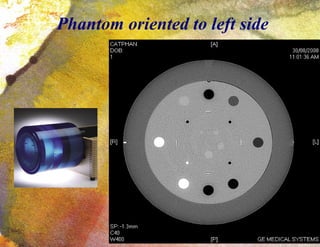

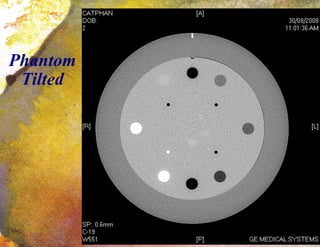

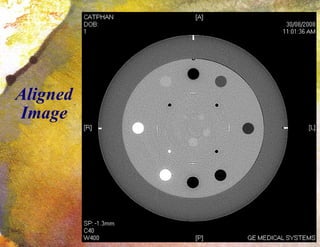

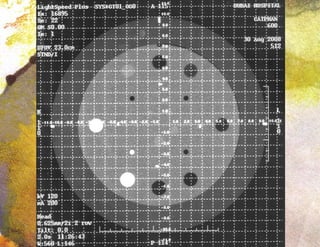

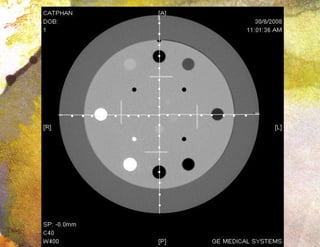

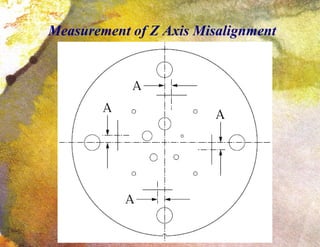

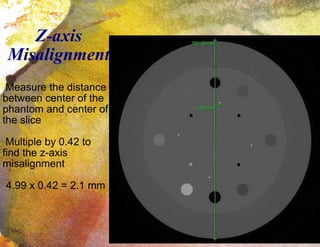

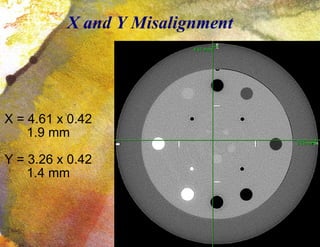

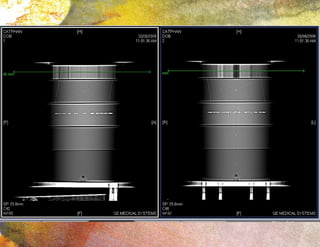

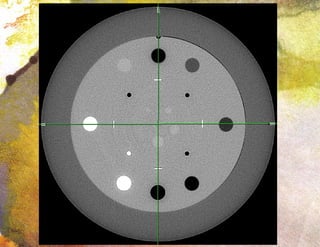

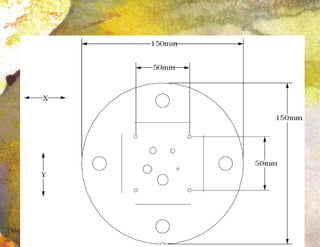

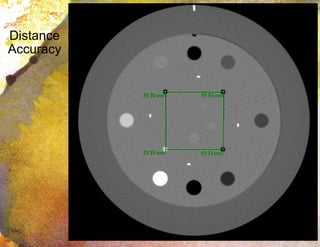

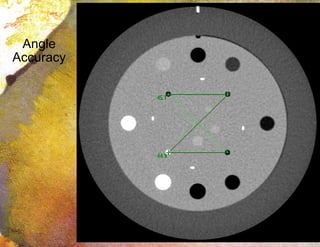

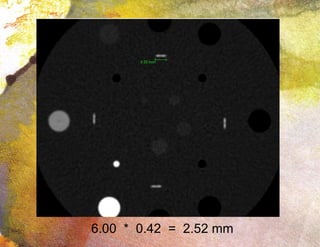

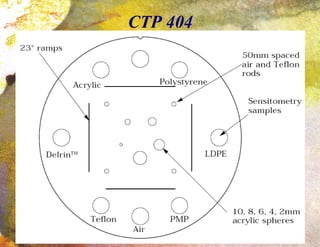

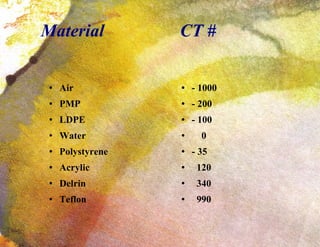

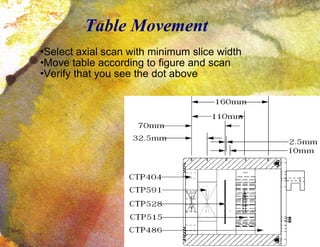

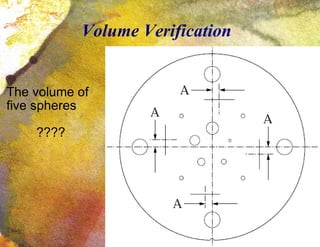

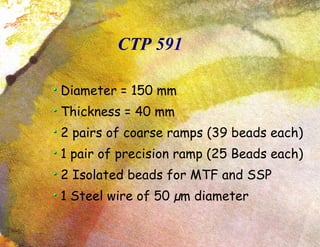

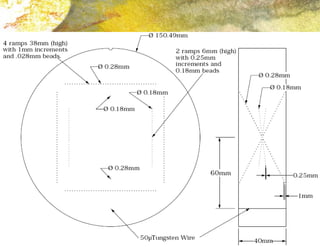

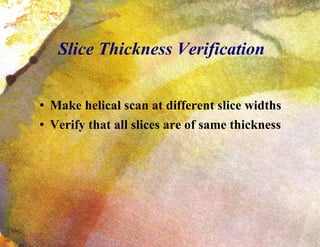

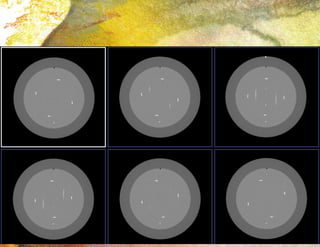

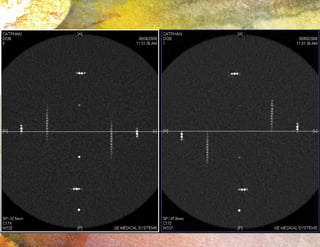

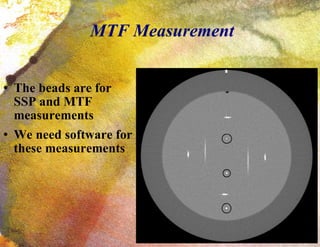

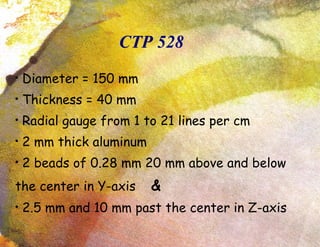

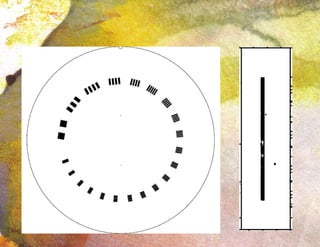

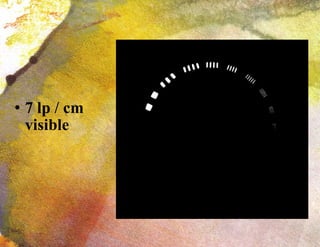

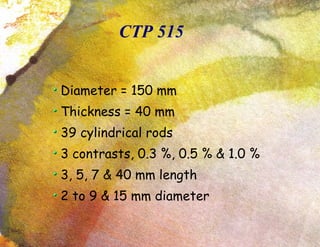

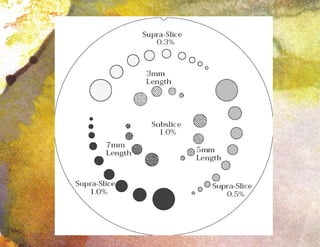

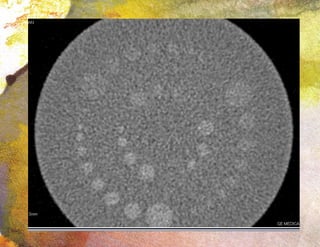

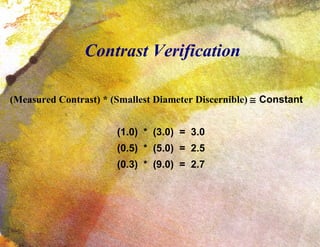

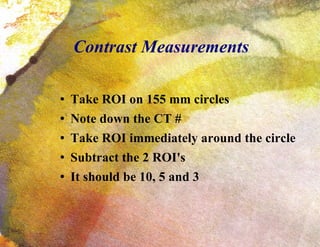

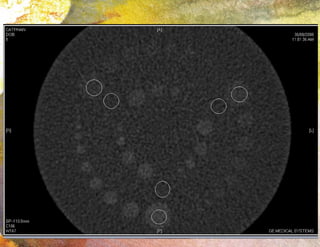

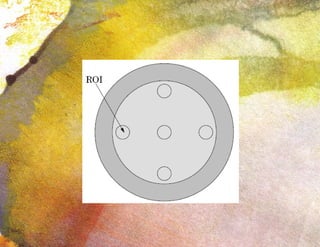

The document discusses performance testing of a computer tomography (CT) scanner using various modules of the CATPHAN phantom. It provides instructions on how to use the different modules to test: [1] laser alignment accuracy, slice thickness accuracy, low contrast detectability, and uniformity; [2] patient alignment system accuracy and circular symmetry; [3] sensitometry and effects of changing kV. Proper phantom positioning and avoiding manual movement are emphasized to obtain reliable results.