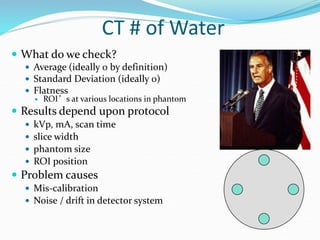

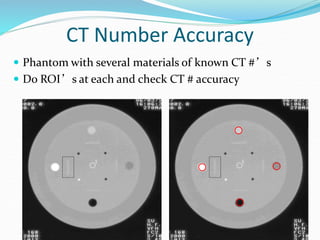

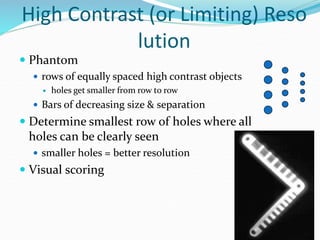

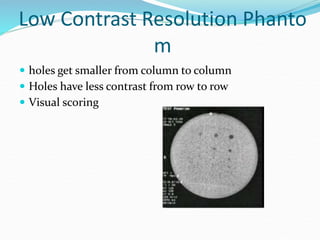

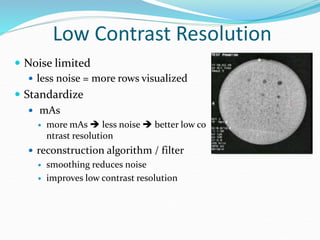

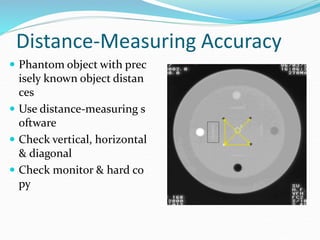

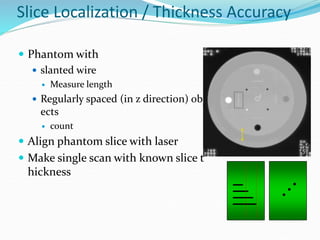

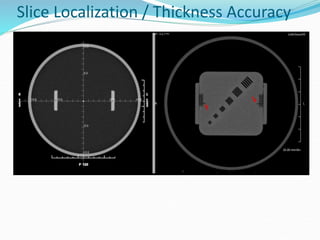

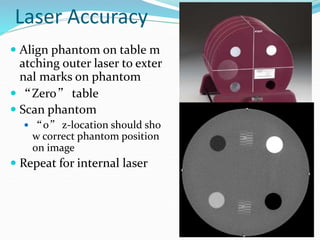

This document discusses quality control procedures for CT scanners, including checking image quality metrics like resolution, noise, and CT number accuracy using phantoms. Regular quality control is recommended to establish baselines, identify potential problems early, and reduce downtime. Various tests are described to check parameters like resolution, noise, CT numbers, distance measurement accuracy, slice thickness, table movement, and laser alignment using specialized phantoms and protocols.