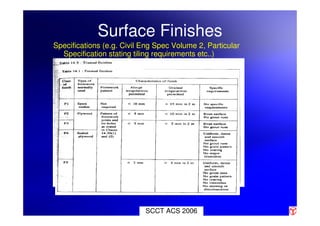

This document provides an overview of quality assurance considerations for precast concrete products. It discusses definitions of precast concrete, examples of precast products, quality systems, production practices, materials, finishes, handling, storage and other factors. Quality assurance requires consideration of safety, facilities, moulds, hardware installation, curing, materials, finishing, handling equipment and more to ensure structural integrity and acceptable appearance of precast concrete products. Mock-ups, standards, lighting and expert evaluation are used to define acceptable surface finishes.