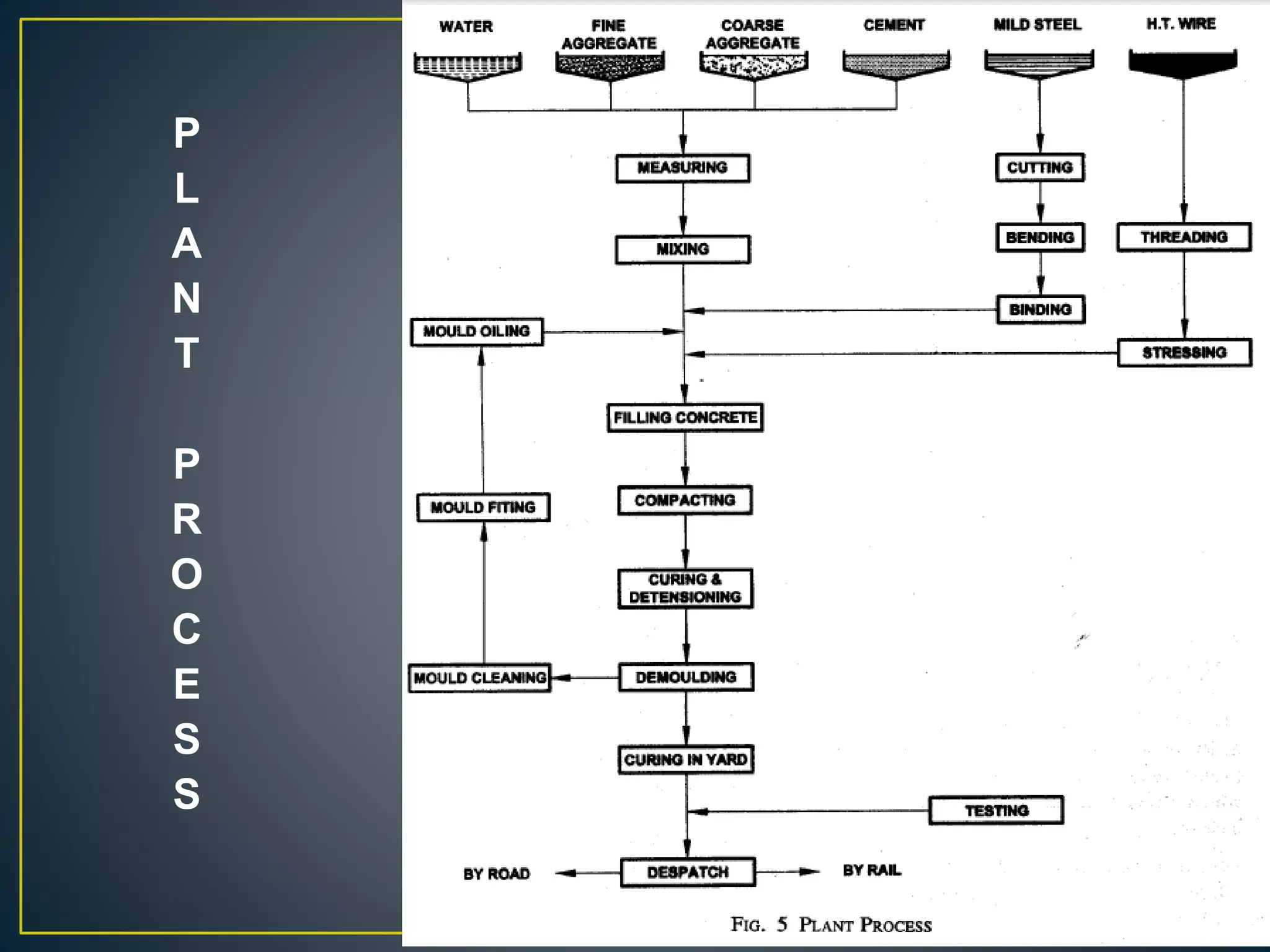

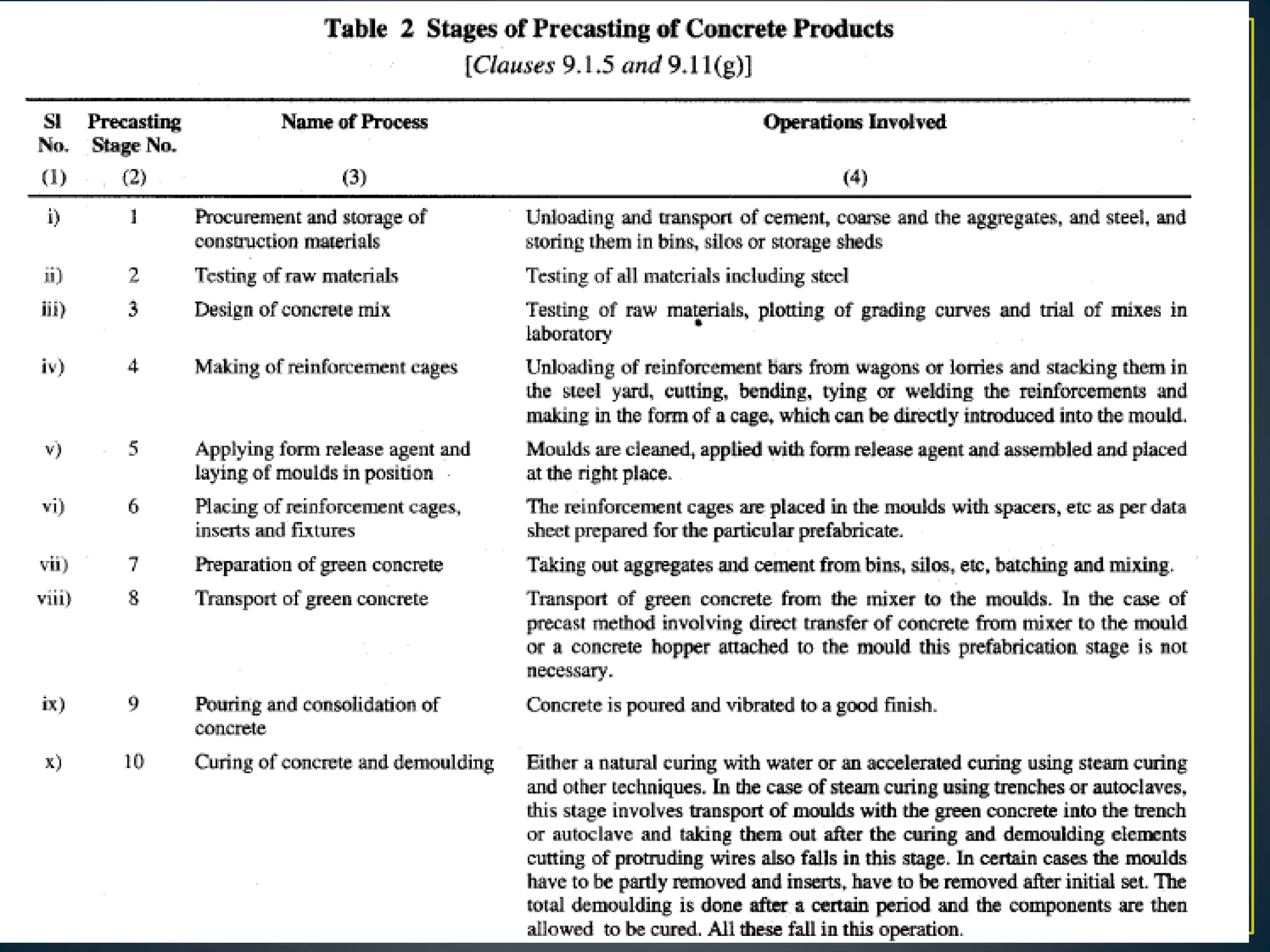

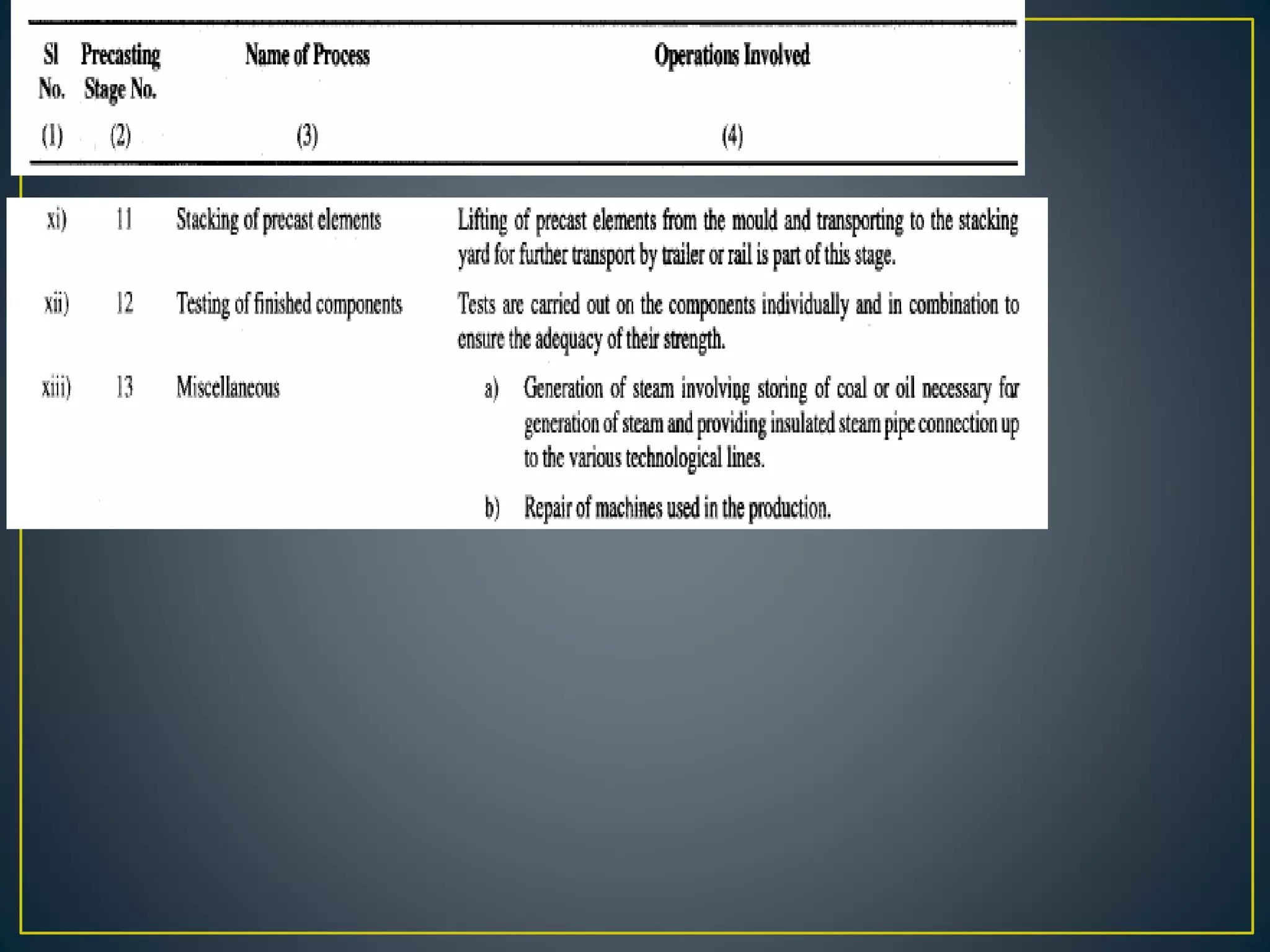

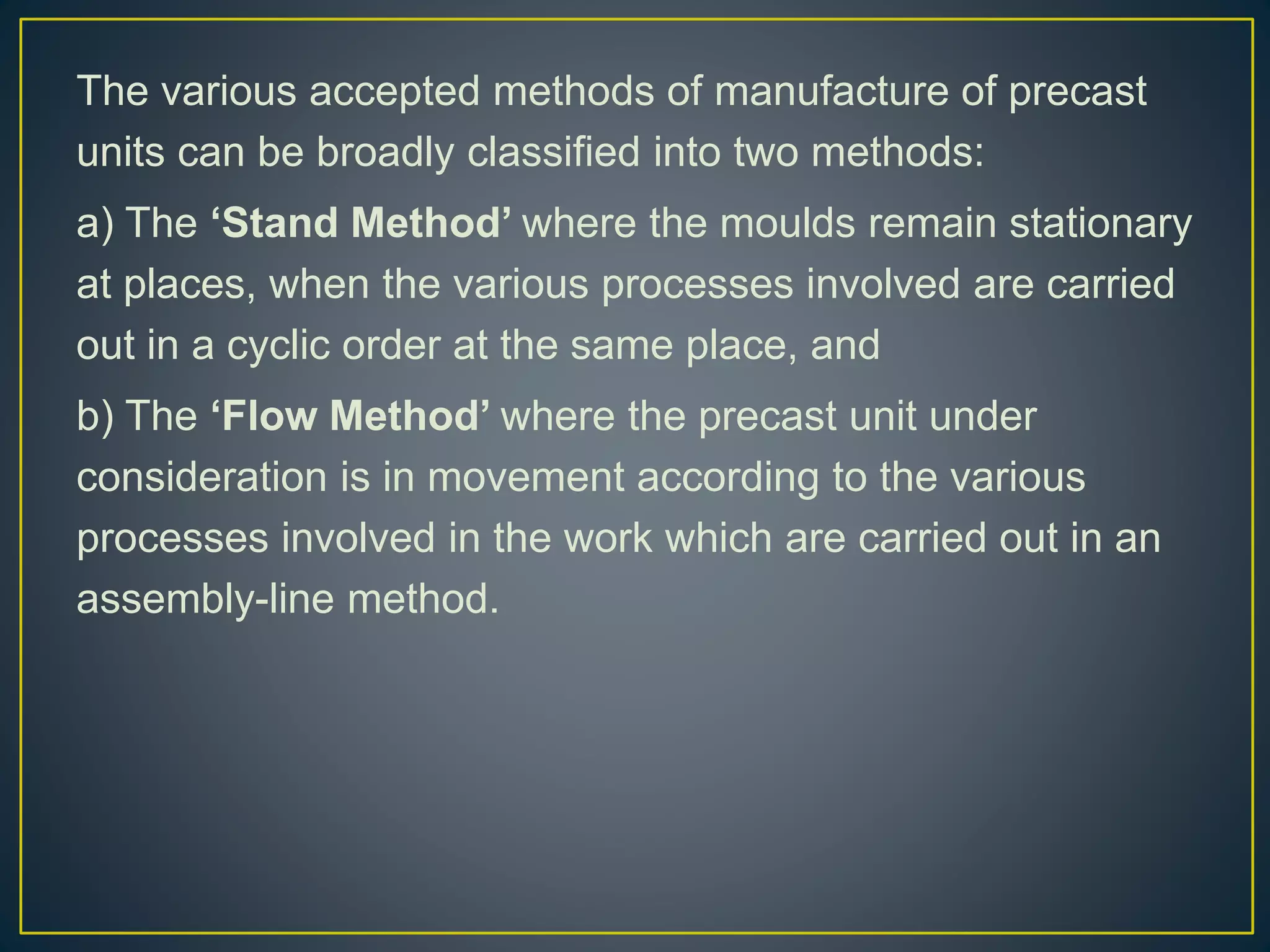

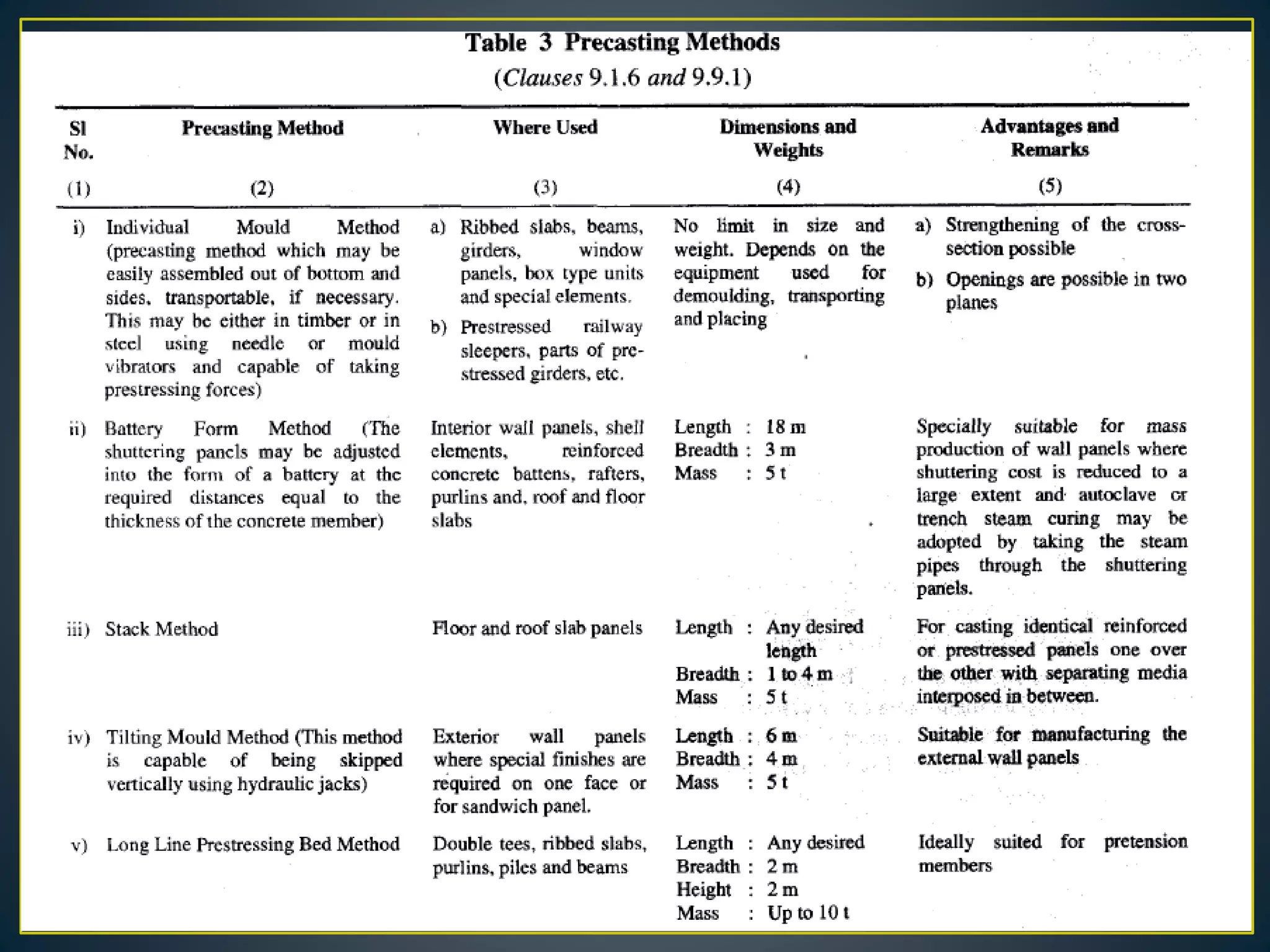

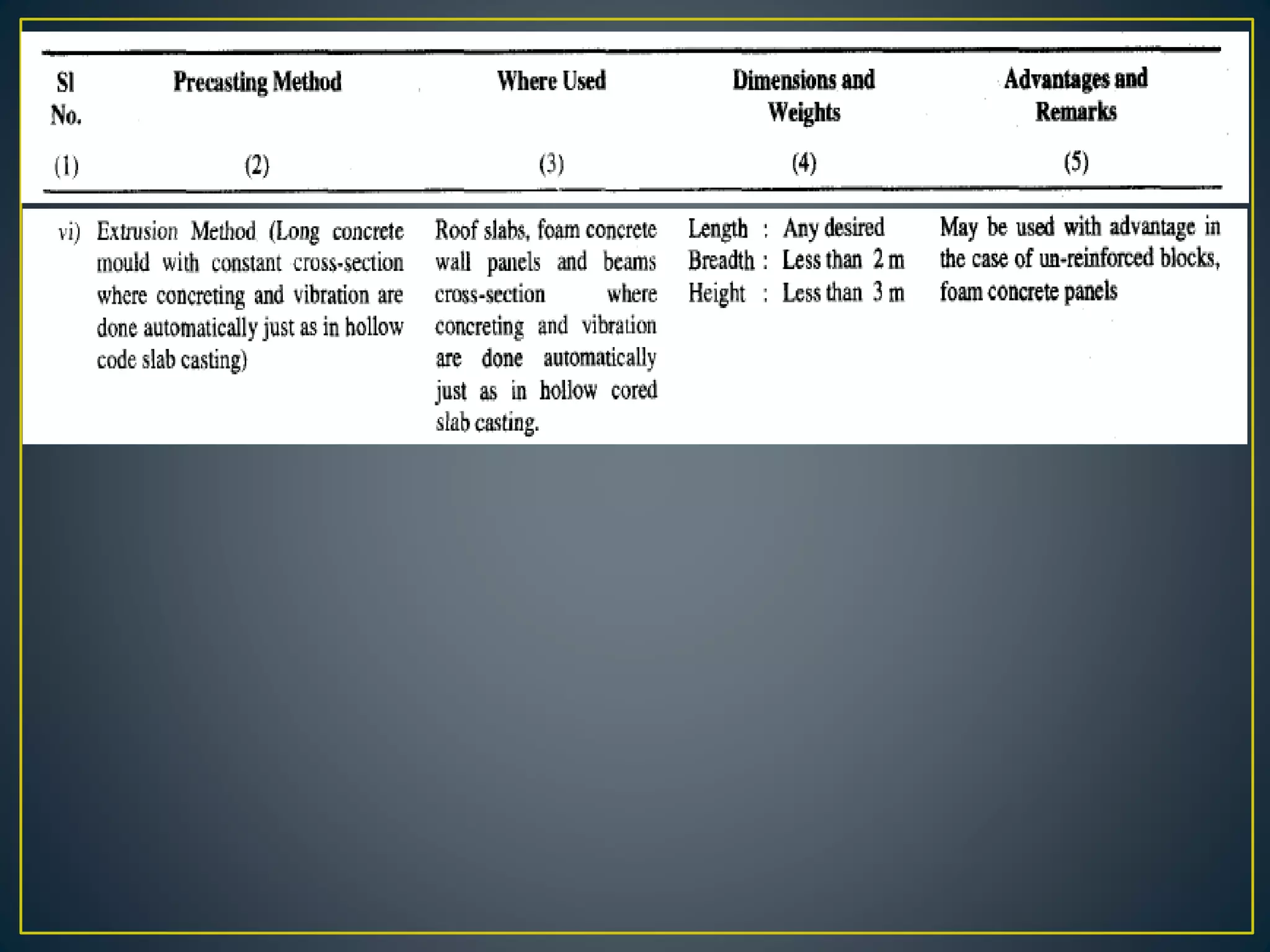

This document discusses different methods for manufacturing precast concrete components, including factory prefabrication, site precasting, and semi-mechanized and fully-mechanized production. It describes the main processes like forming, reinforcement, pouring, curing, and demolding, as well as auxiliary processes needed for production. Transportation of components and their erection are also outlined. The document classifies manufacturing methods as either stationary "stand" molds or moving "flow" molds in an assembly line.