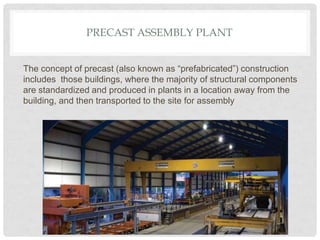

The document discusses precast and cast-in-place concrete construction methods. Precast concrete involves casting structural elements off-site in a controlled environment, then transporting them to the construction site for assembly. Cast-in-place involves pouring concrete directly on-site. Precast offers benefits like faster construction, quality control, and the ability to work independently of weather. However, it requires more joints and handling equipment. Cast-in-place allows for monolithic structures but offers less construction speed and quality control. Both methods have advantages depending on the size and needs of the specific project.