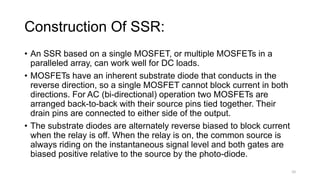

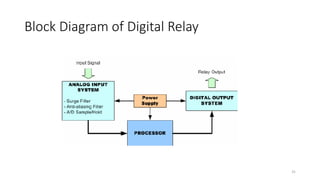

This document discusses different types of relays including electrical, mechanical, and digital relays. It focuses on solid state relays (SSRs) and electromechanical relays, comparing their construction, working principles, advantages, and disadvantages. SSRs use semiconductors like thyristors and transistors to switch currents electronically, while electromechanical relays use an electromagnetic coil to move contacts and switch circuits mechanically. SSRs have no moving parts but lower overload capacity, while electromechanical relays can withstand higher loads but have contacts that wear out over time.