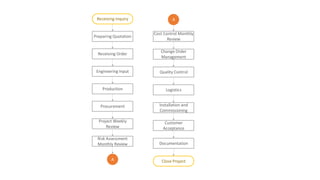

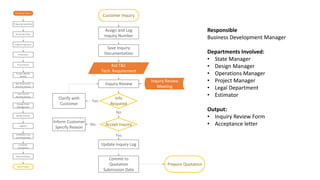

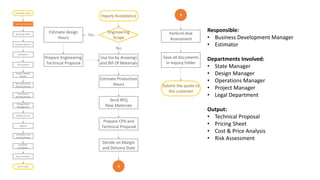

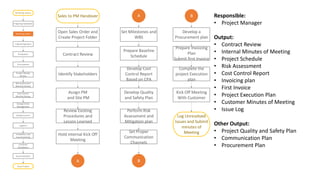

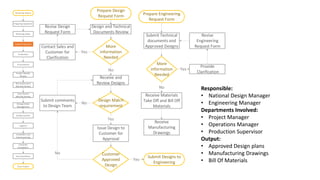

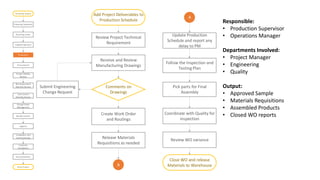

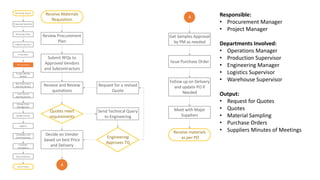

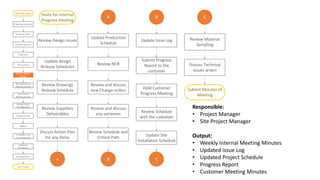

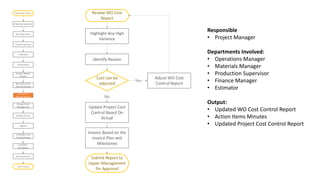

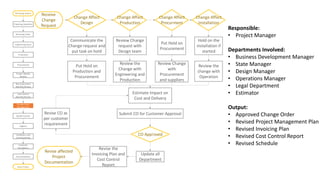

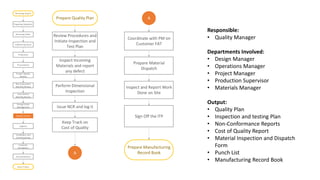

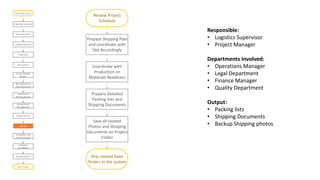

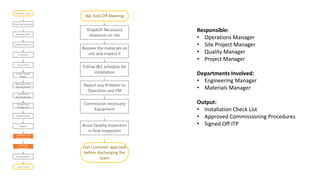

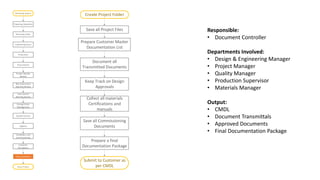

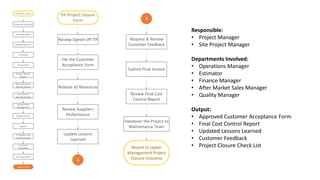

This document outlines the key steps and processes involved in project and production management. It includes receiving customer inquiries, preparing quotations, receiving orders, engineering input, production, project reviews, risk assessments, installation and commissioning, change management, quality control, cost control, procurement, customer acceptance, documentation, and closing projects. Key responsibilities and outputs are defined for each step. The overall process aims to deliver successful projects from initial customer contact through to final handover and closure.