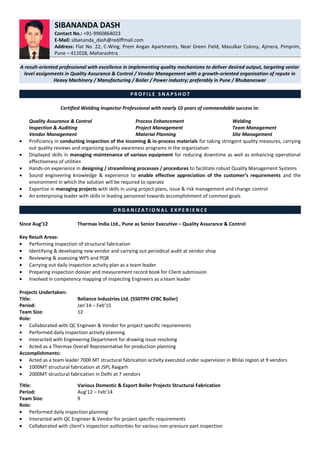

Sibananda Dash is a certified welding inspector professional with 10 years of experience in quality assurance, control, inspection, and auditing. He is currently a senior executive of quality assurance and control at Thermax India Ltd. in Pune. He is seeking a senior level position in quality assurance and control or vendor management in the heavy machinery, manufacturing, boiler, or power industries, preferably in Pune or Bhubaneswar.