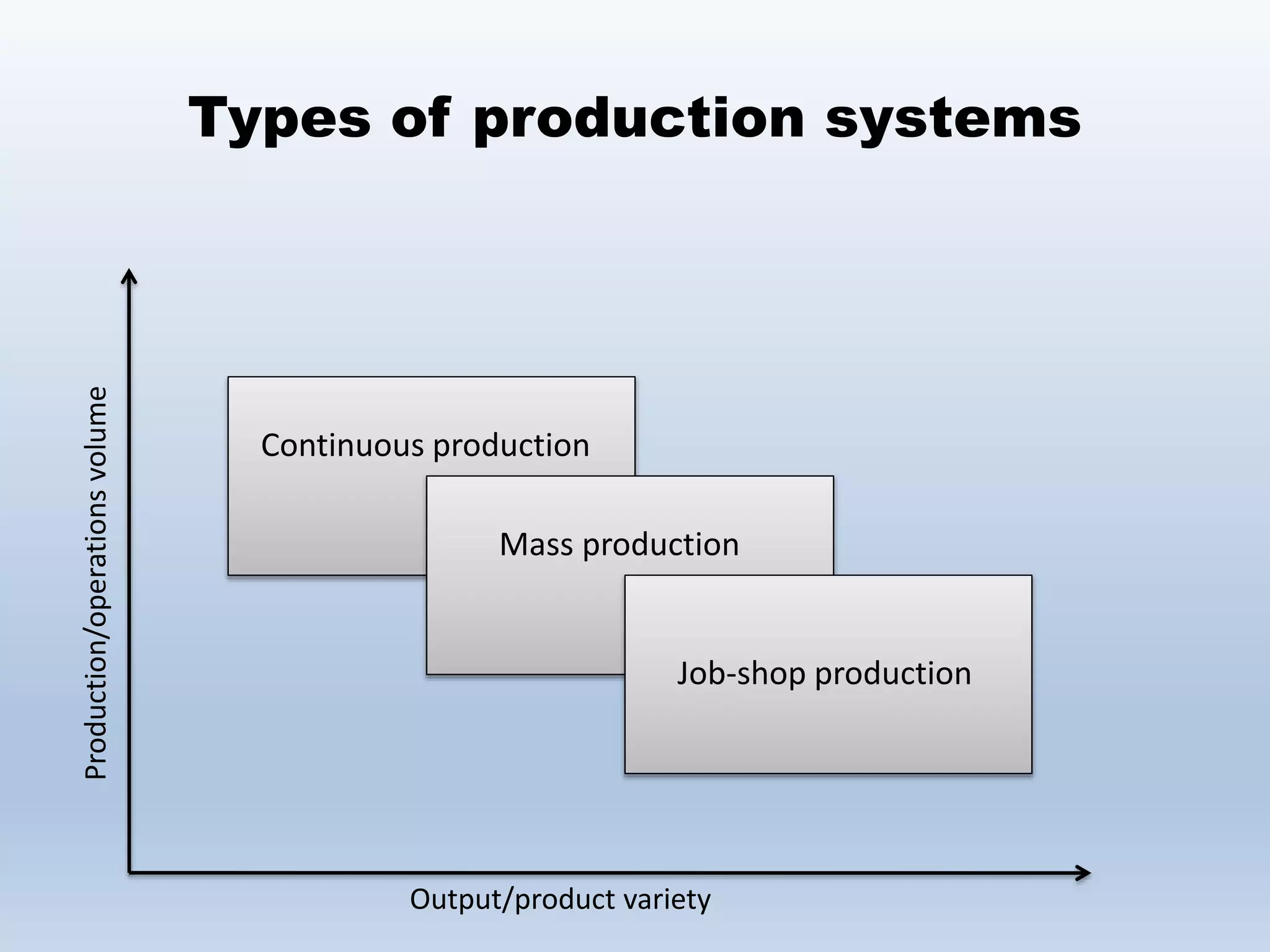

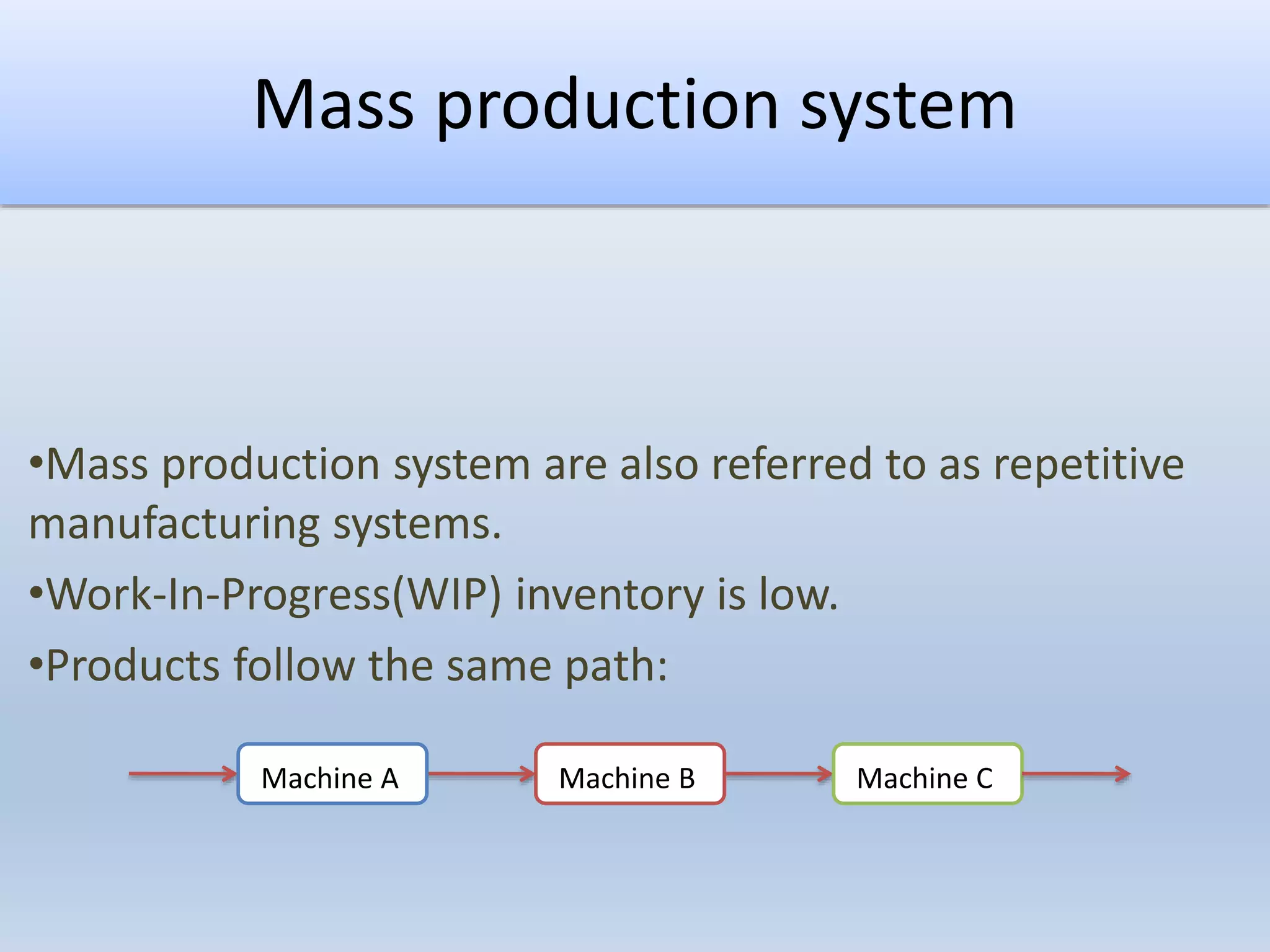

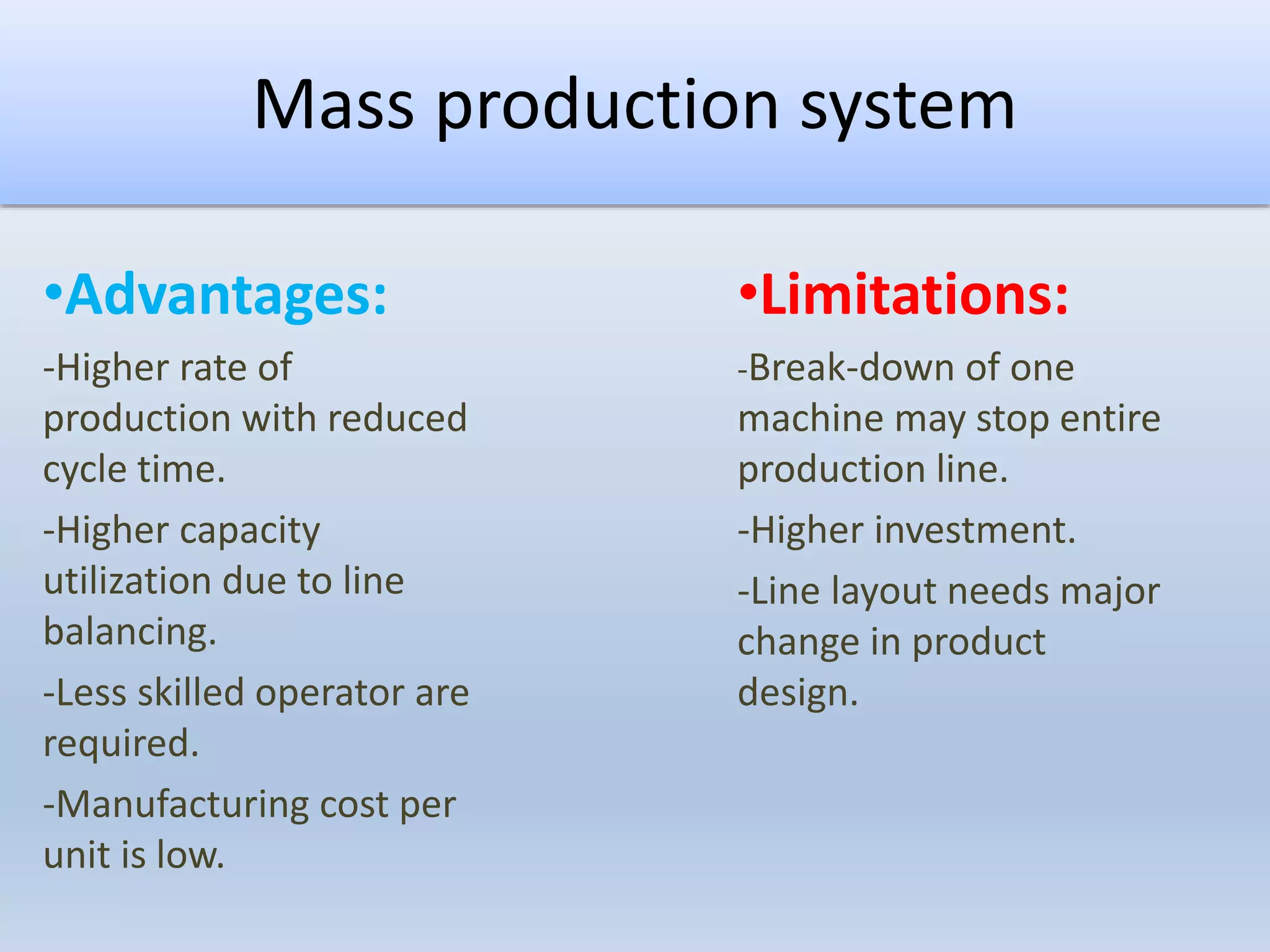

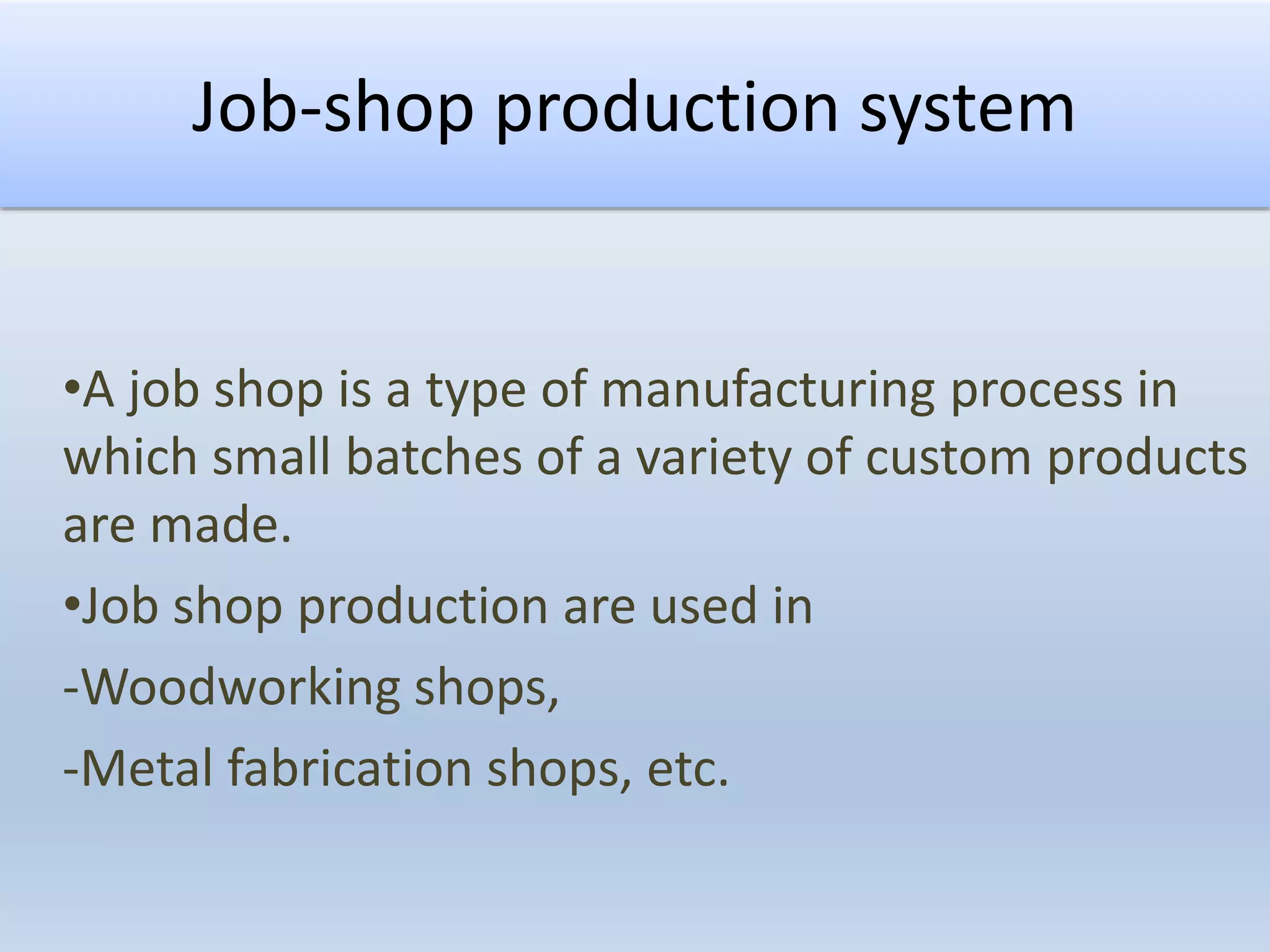

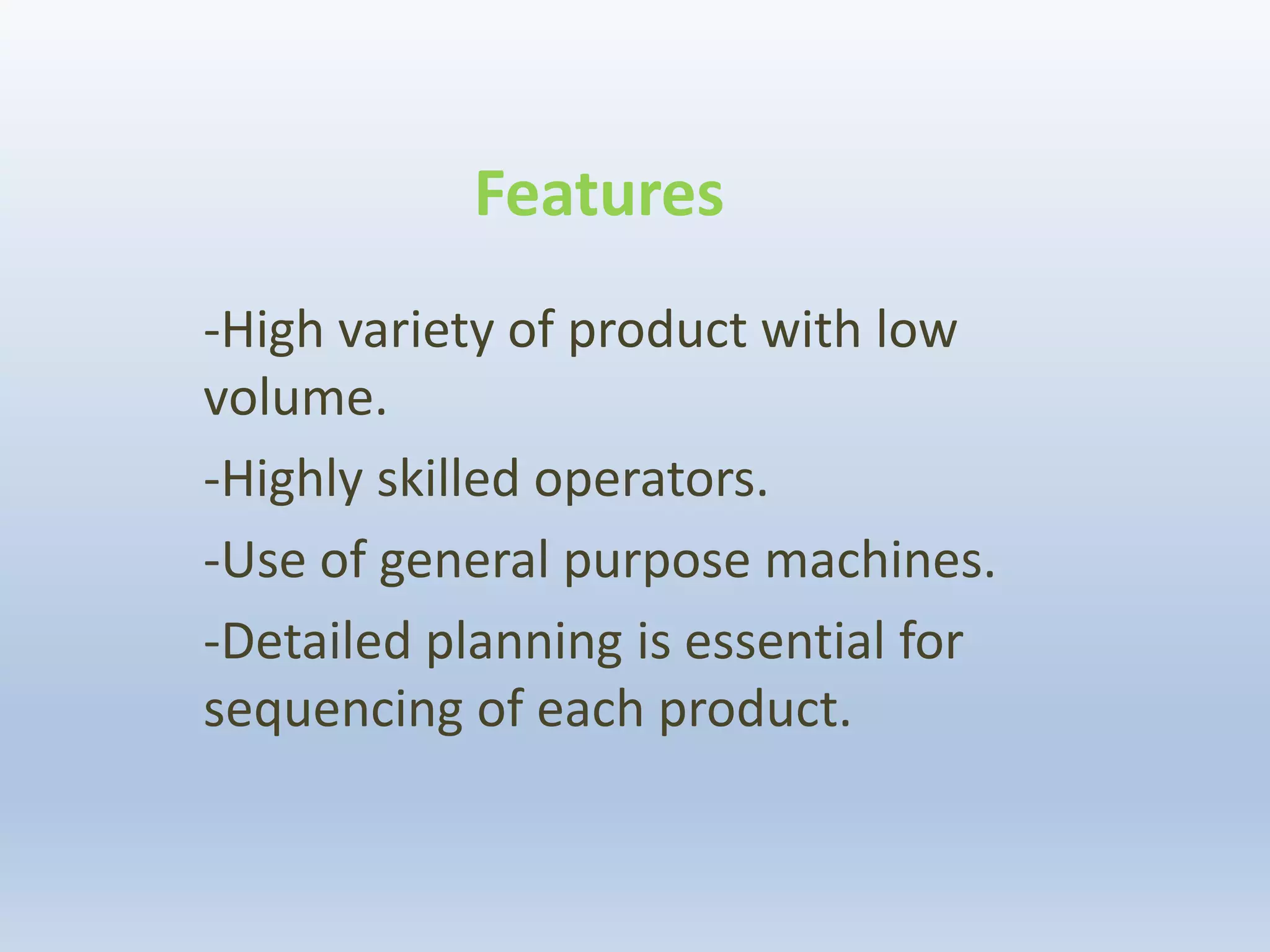

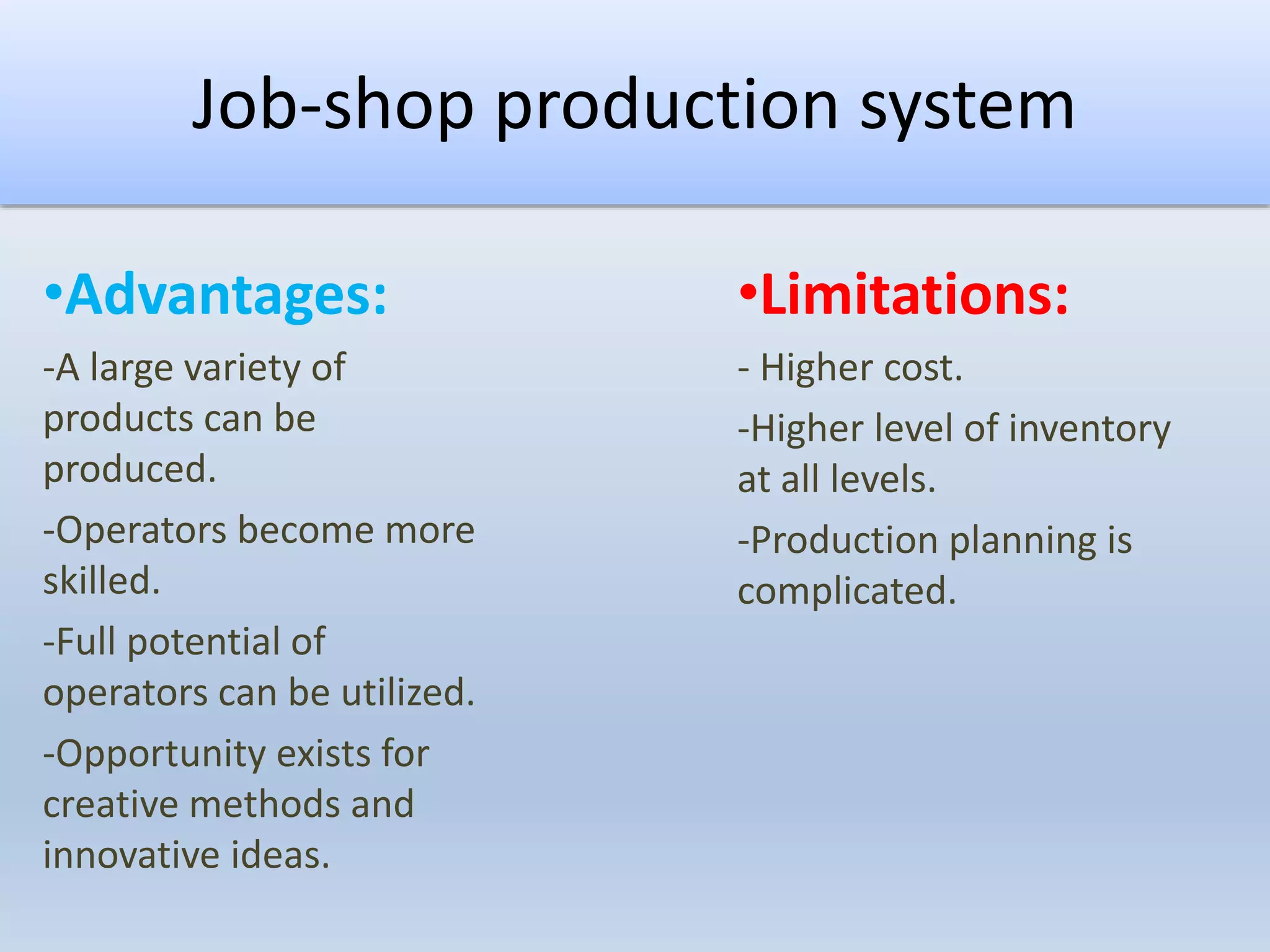

The document outlines various production systems in organizations, including mass production, job-shop production, and batch manufacturing, highlighting their features, advantages, and limitations. Mass production focuses on high volume and standardization with low costs, while job-shop production allows for high variety and customization at a higher cost. Batch manufacturing sits between the two, offering flexibility but with complexities in planning and material handling.