This document discusses packaging materials used for spices in India. It provides details on:

1) The major types of packaging used for spices include glass bottles, flexible pouches made of laminated films such as PET, BOPP, and LDPE. These materials provide properties like barrier to moisture and gases extending shelf life.

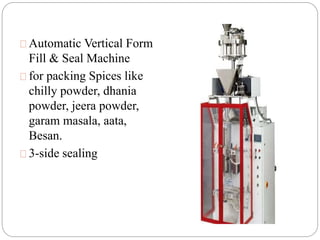

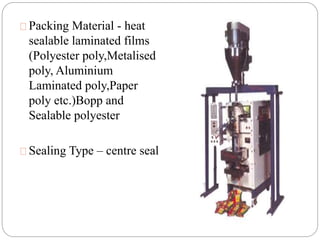

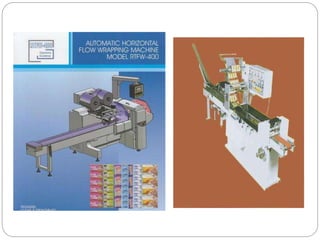

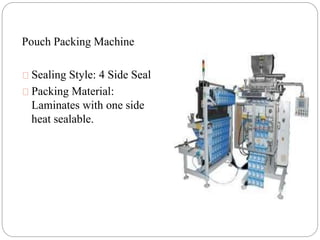

2) The main equipment used for packaging spices are form fill seal machines and pouch packing machines which use heat sealable laminated films to package spices into pouches and bottles.

3) Key test methods evaluated packaging materials strength and integrity including squeeze tests for bottles and tear resistance and tensile strength tests for plastic films.