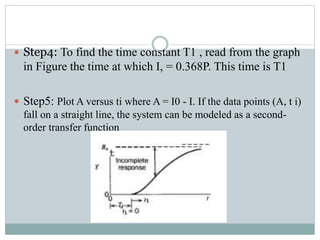

The document discusses process identification, which involves experimentally determining the dynamic behavior of industrial processes too complex to model using fundamental principles. Process identification provides models like process reaction curves from step inputs, frequency response diagrams from sinusoidal inputs, and pulse responses. These models are useful for control system design. The document specifically describes using a step test and semi-log plotting of the process reaction curve to identify the parameters of a second-order process model with transport lag, including the time constants T1 and T2 and the process gain Kp.