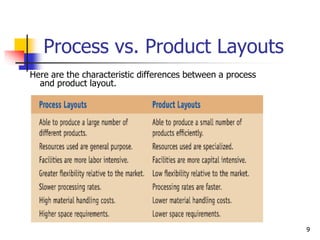

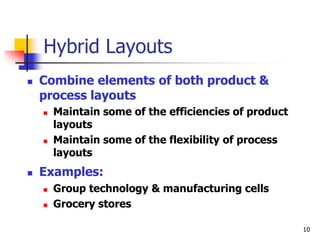

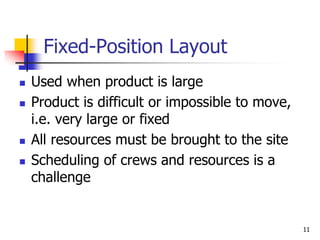

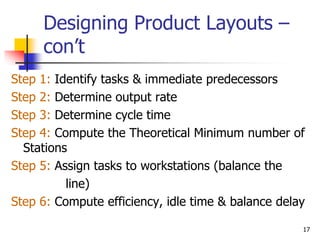

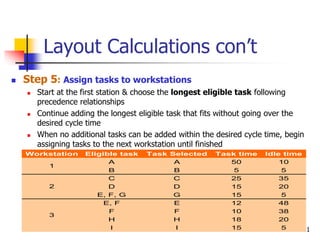

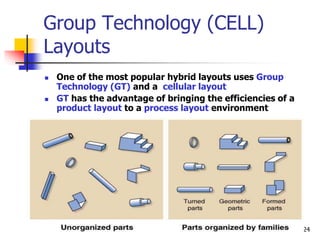

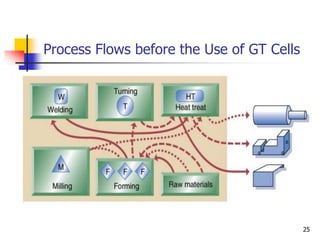

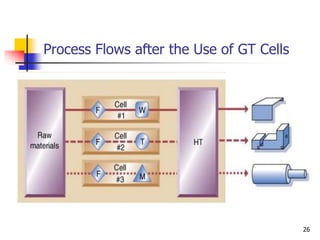

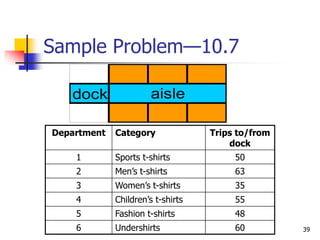

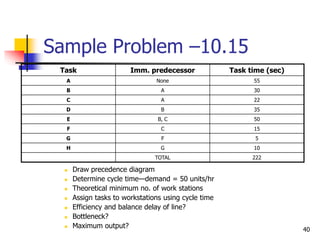

The document discusses facility layout planning. It defines layout planning as deciding on the best physical arrangement of resources within a facility. It identifies four main types of layouts - process layouts, which group similar resources; product layouts, designed for specific products; hybrid layouts, combining aspects of process and product; and fixed-position layouts for large products. The document outlines steps for designing process and product layouts, and compares their characteristics. It also discusses hybrid layouts like group technology cells and highlights the importance of layout planning for efficient operations.