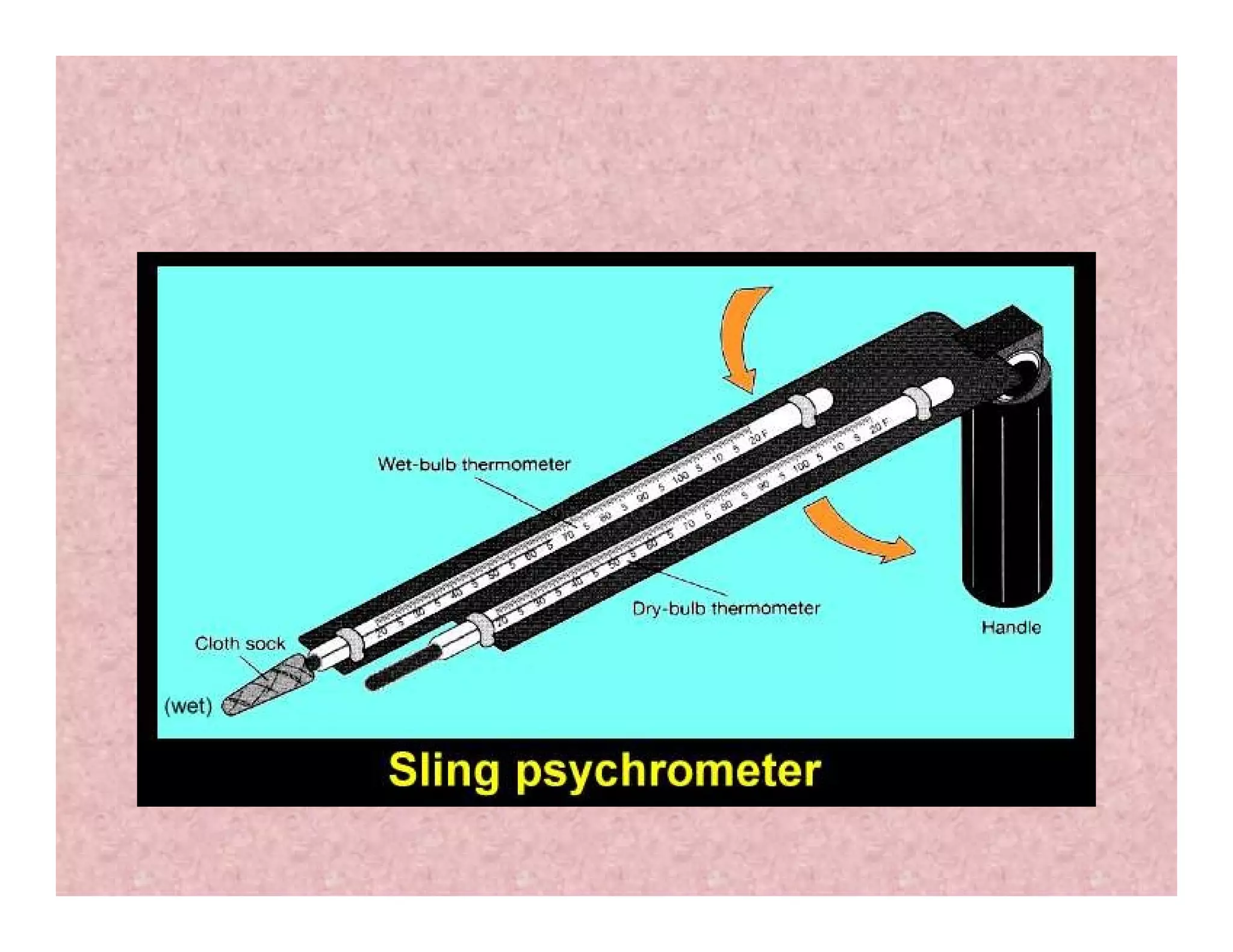

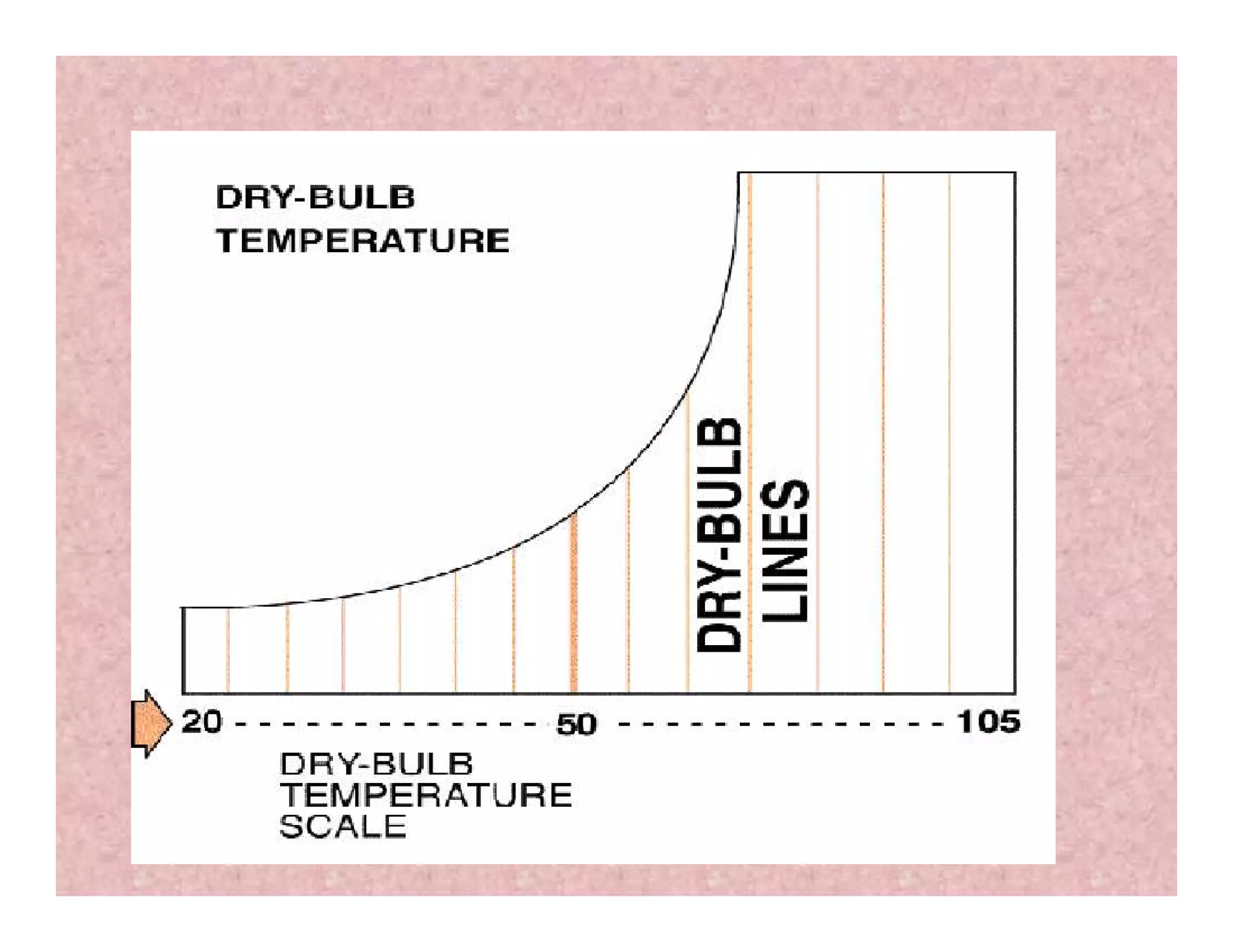

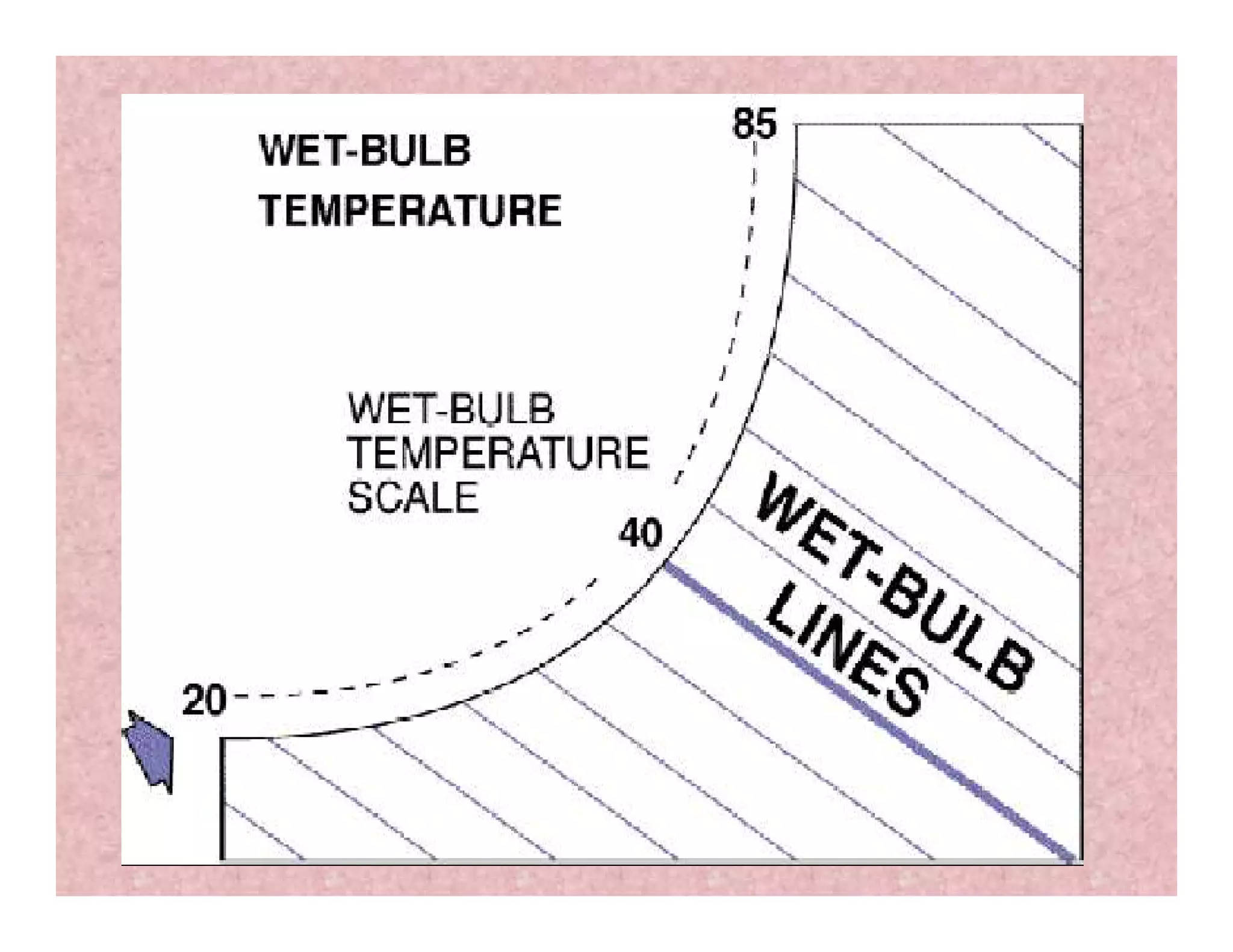

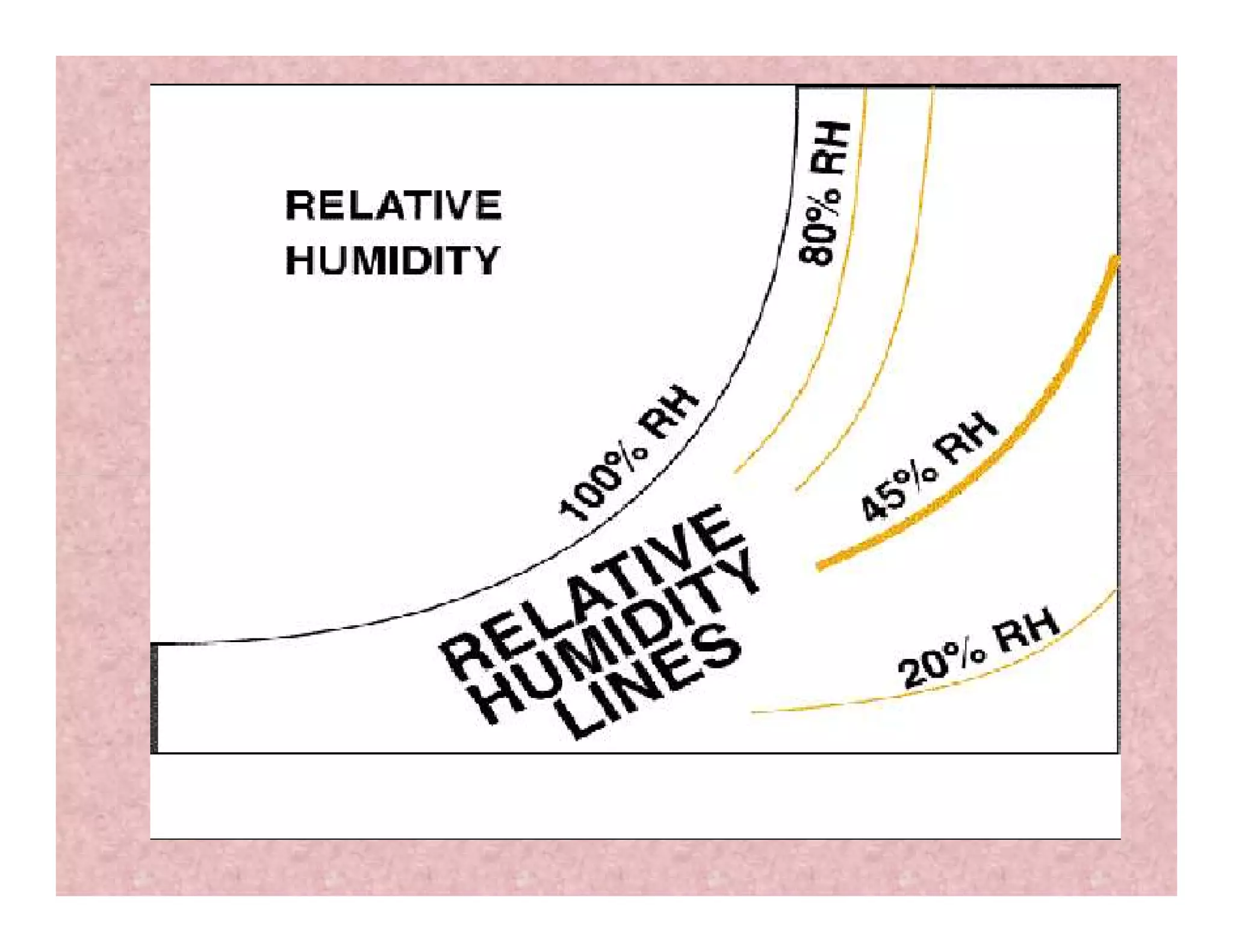

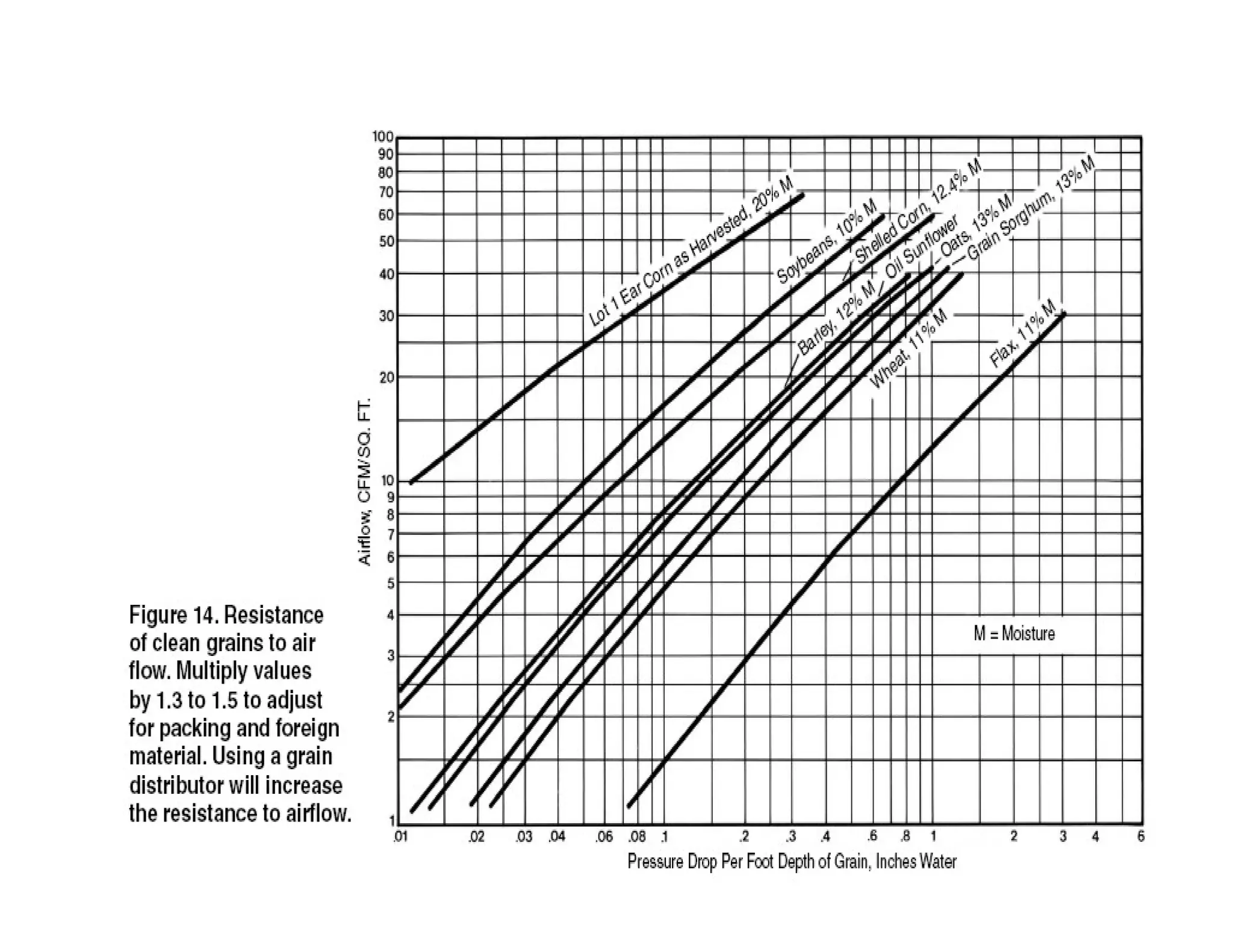

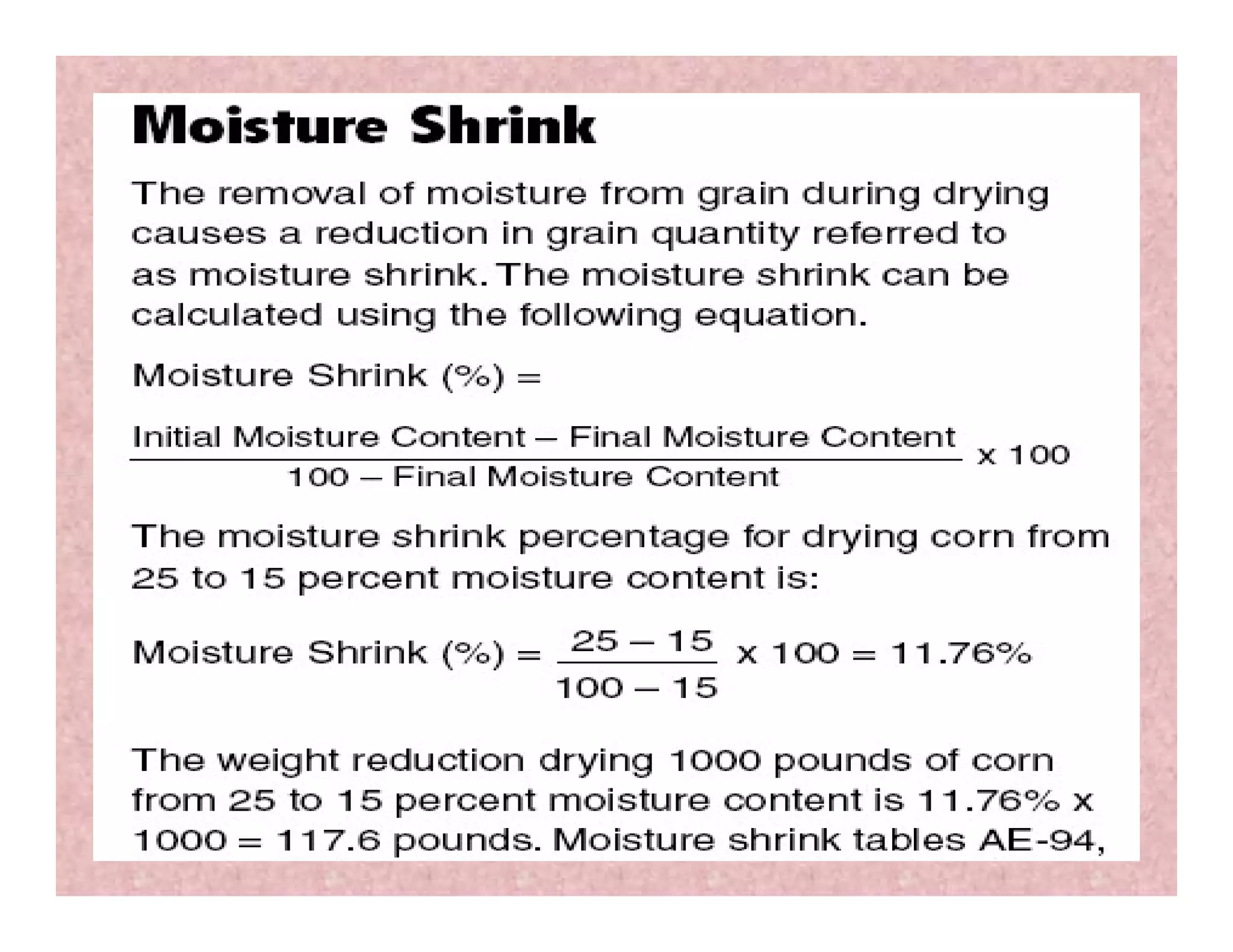

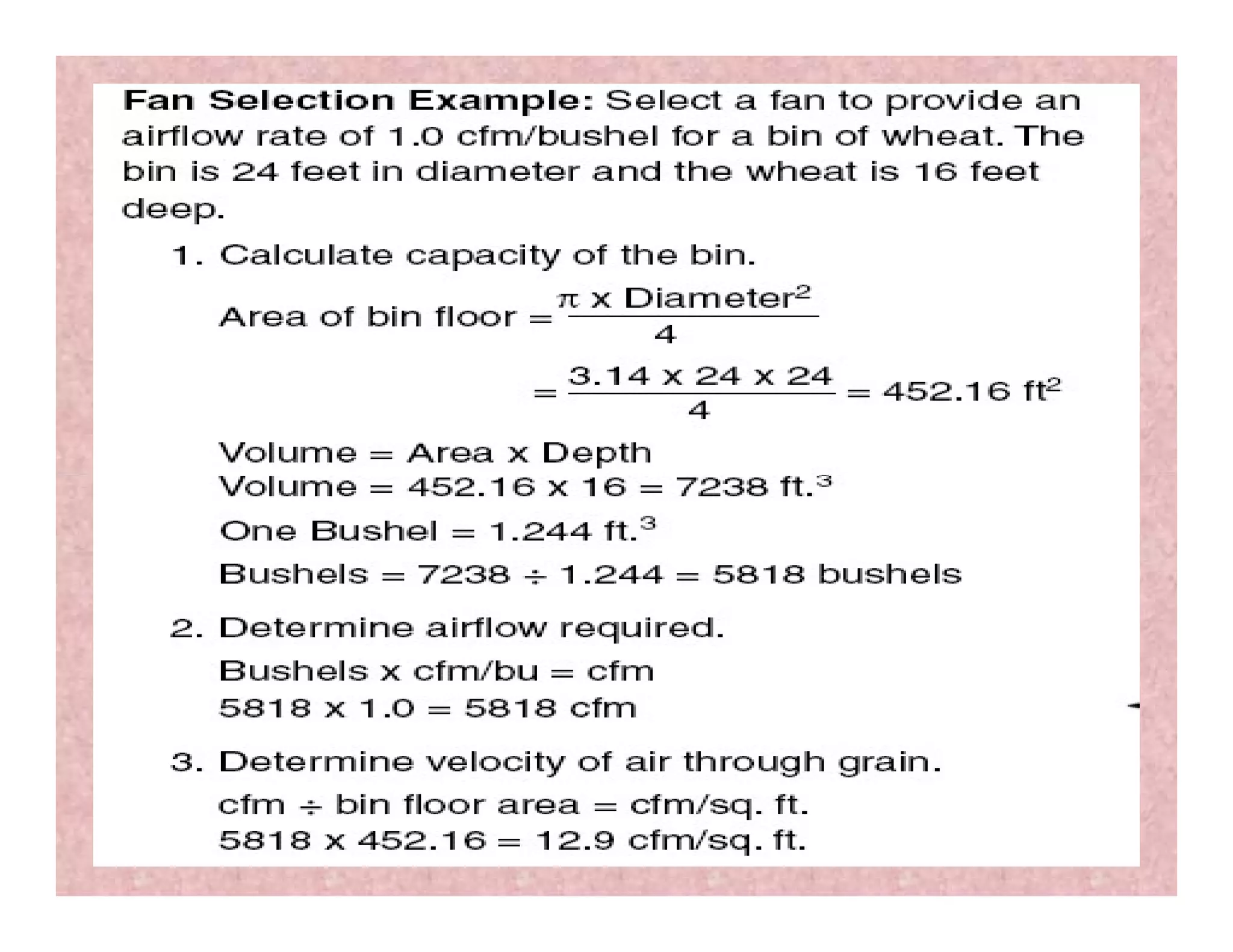

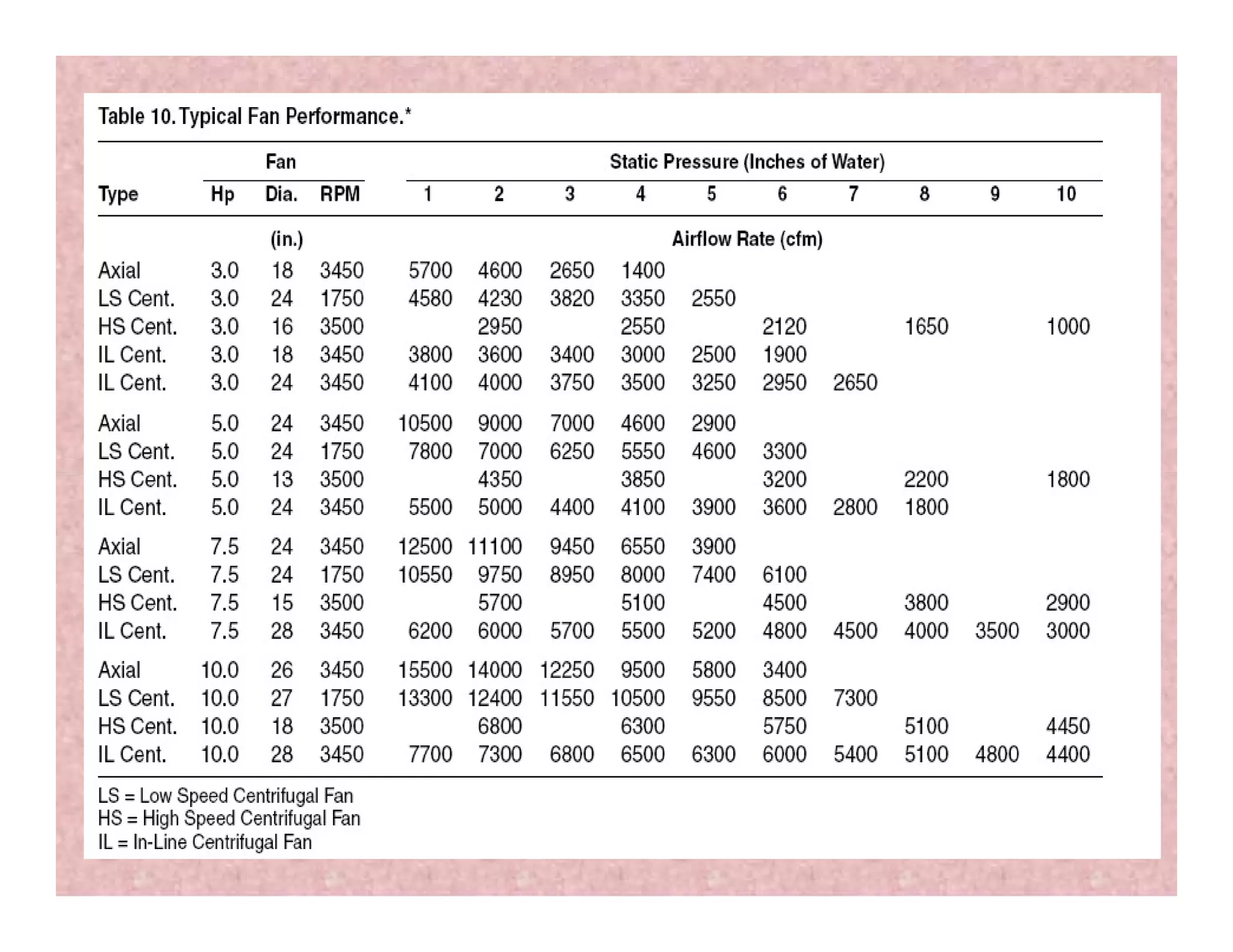

This document provides information about seed drying principles and methods. It discusses that drying seeds reduces moisture content to allow for better storage and prevents microbial growth. The main methods covered are sun drying and forced air drying. Forced air drying uses fans to circulate dry or heated air through seeds to evaporate moisture based on air temperature and humidity levels. Recommendations are provided for optimal drying temperatures and depths for different seed types, as well as safe moisture contents for storage.