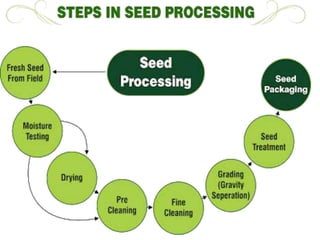

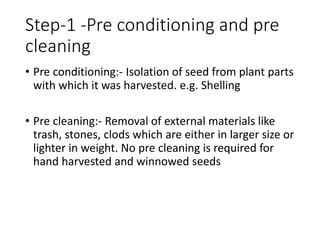

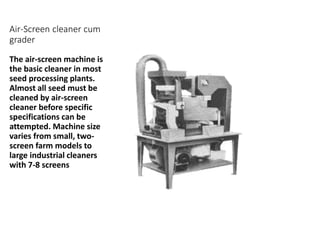

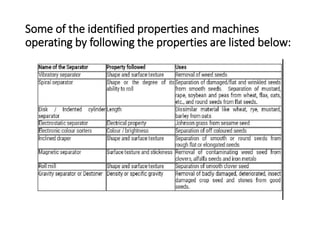

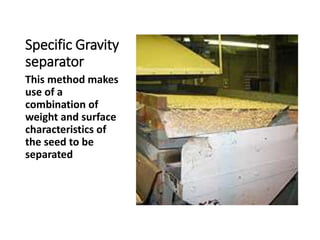

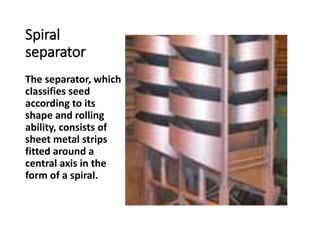

This document outlines the key steps involved in seed processing, which includes pre-conditioning, cleaning, and grading. Pre-conditioning involves removing plant parts from harvested seeds through shelling. Cleaning is done using air screens and vibrating screens to remove external materials like trash and stones. This is mostly done using an air-screen cleaner. The final step of grading further separates seeds by size, shape, and other physical properties using different machines like specific gravity separators or spiral separators to obtain high quality seeds free of impurities. Seed processing helps improve planting conditions, seed quality, and applies treatments to prevent disease.