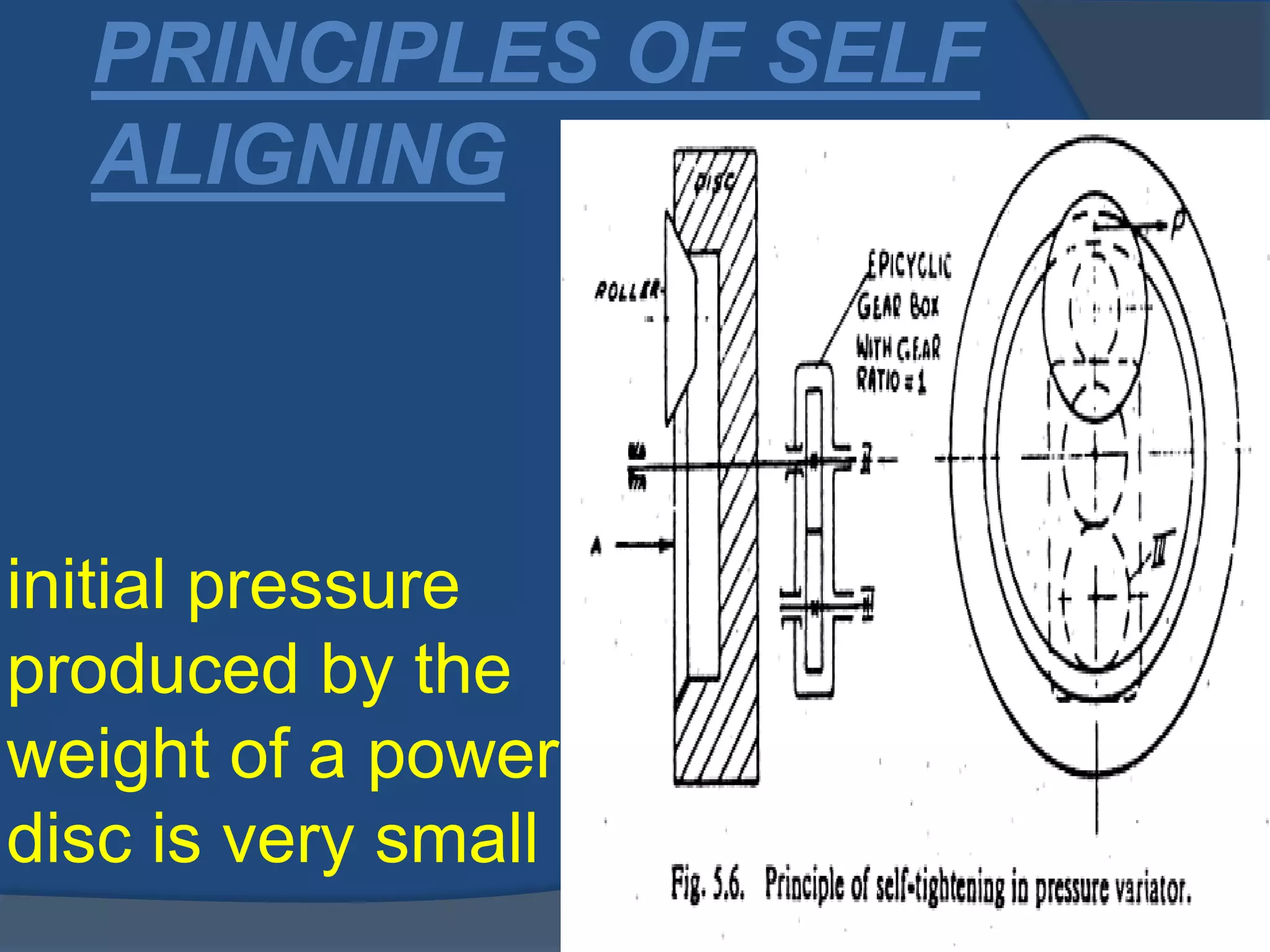

This document summarizes information about continuously variable transmissions (CVTs). It discusses how CVTs can operate over an infinite range of gear ratios compared to fixed gear transmissions. CVTs allow the driving shaft to maintain a constant speed over a variety of output speeds. They provide better efficiency than other transmissions by allowing operation at the most efficient RPM. Applications mentioned include small tractors, combine harvesters, and machine tools. The document also discusses principles of self-aligning CVTs and methods to increase the range of regulation, including using multiple variators, variator-gearbox combinations, and variators with epicyclic mechanisms.