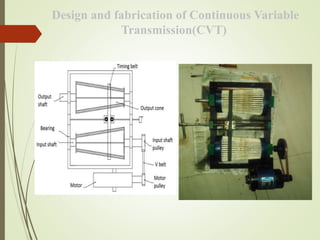

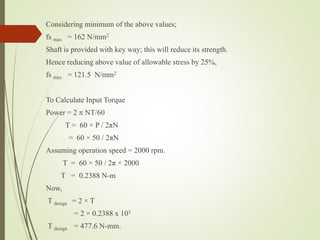

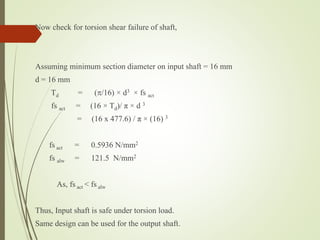

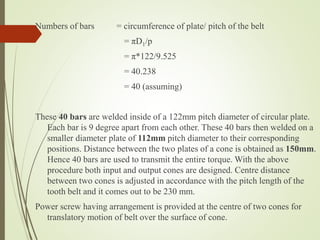

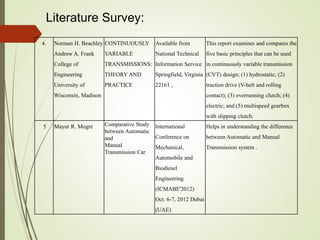

The document details the design and fabrication of a continuously variable transmission (CVT) model, specifically focusing on the cone type CVT. It outlines the objectives, components, and working mechanism of the CVT, along with the materials used and the processes followed in its construction. Additionally, it discusses advantages, future applications, and relevant literature on CVT technology.