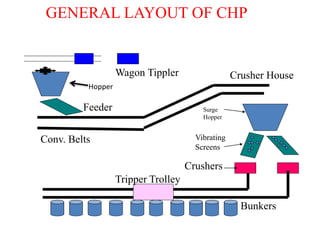

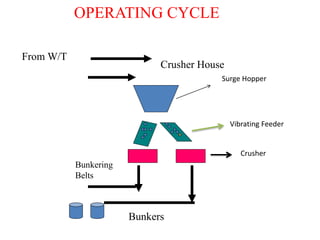

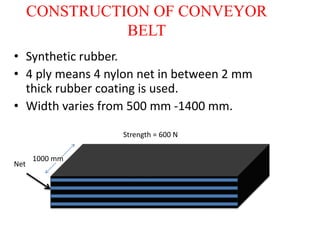

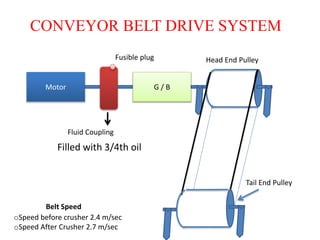

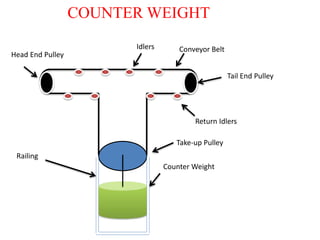

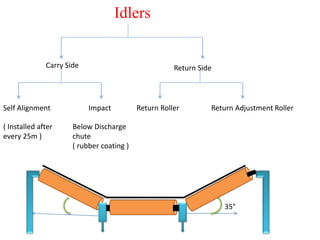

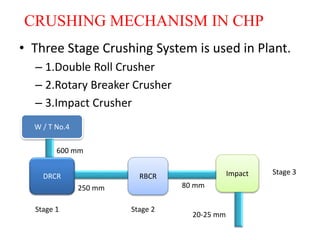

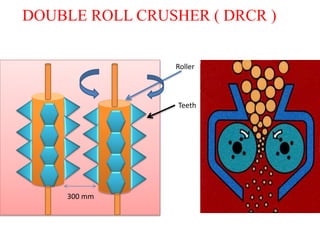

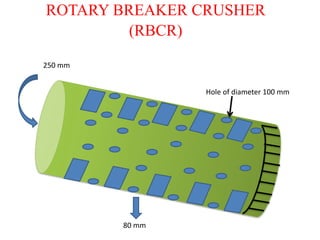

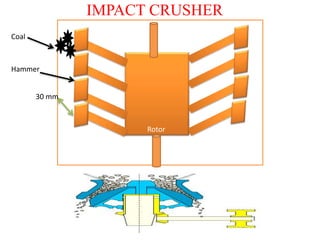

This document provides an overview of the coal handling plant (CHP) at the Rajmahal area of Eastern Coalfields Limited in India. It discusses the general layout of the CHP including wagon tipplers, bunkers, conveyor belts, screens, crushers and hoppers. It also describes the operating cycle and crushing mechanisms used including double roll crushers, rotary breaker crushers, and impact crushers to crush coal from 600mm to 20-25mm.