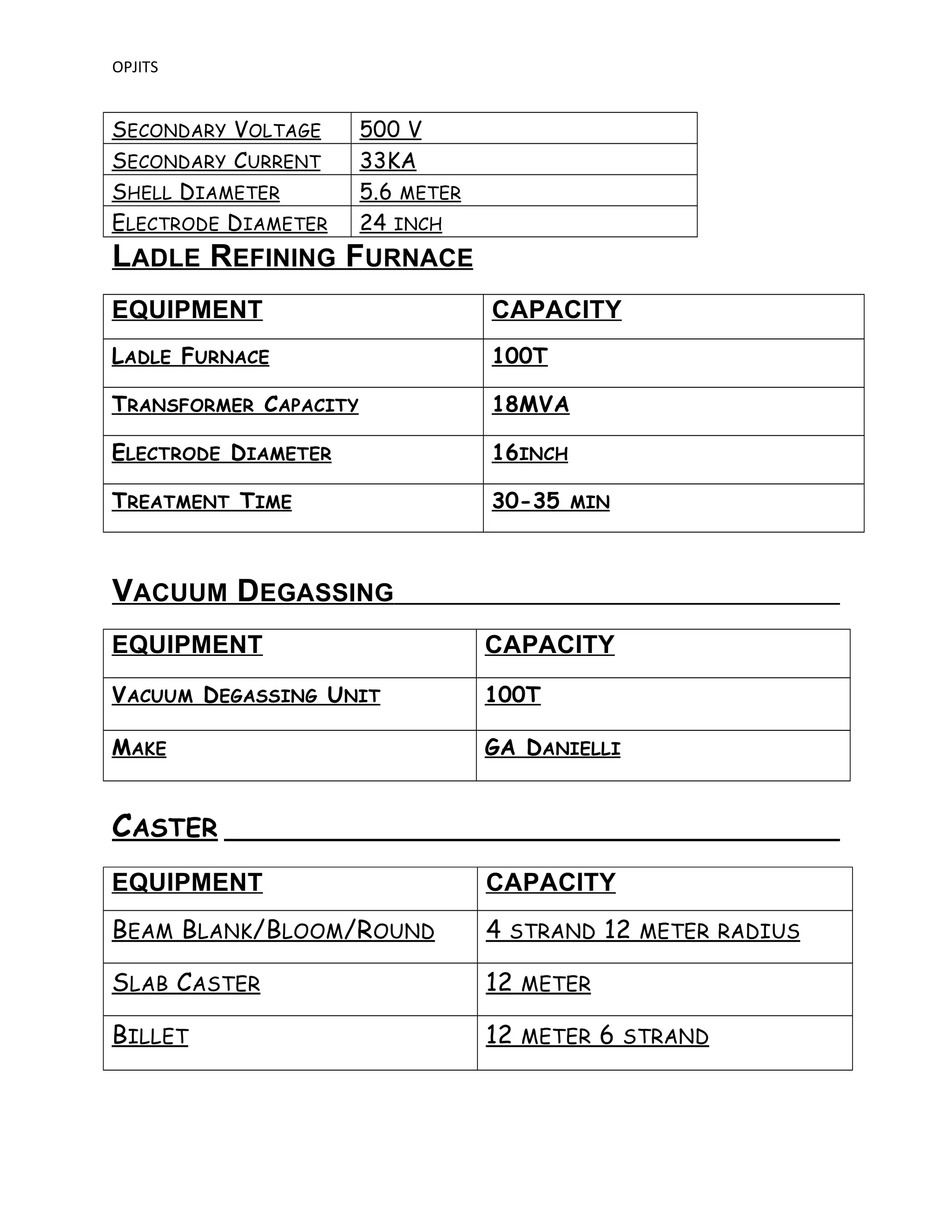

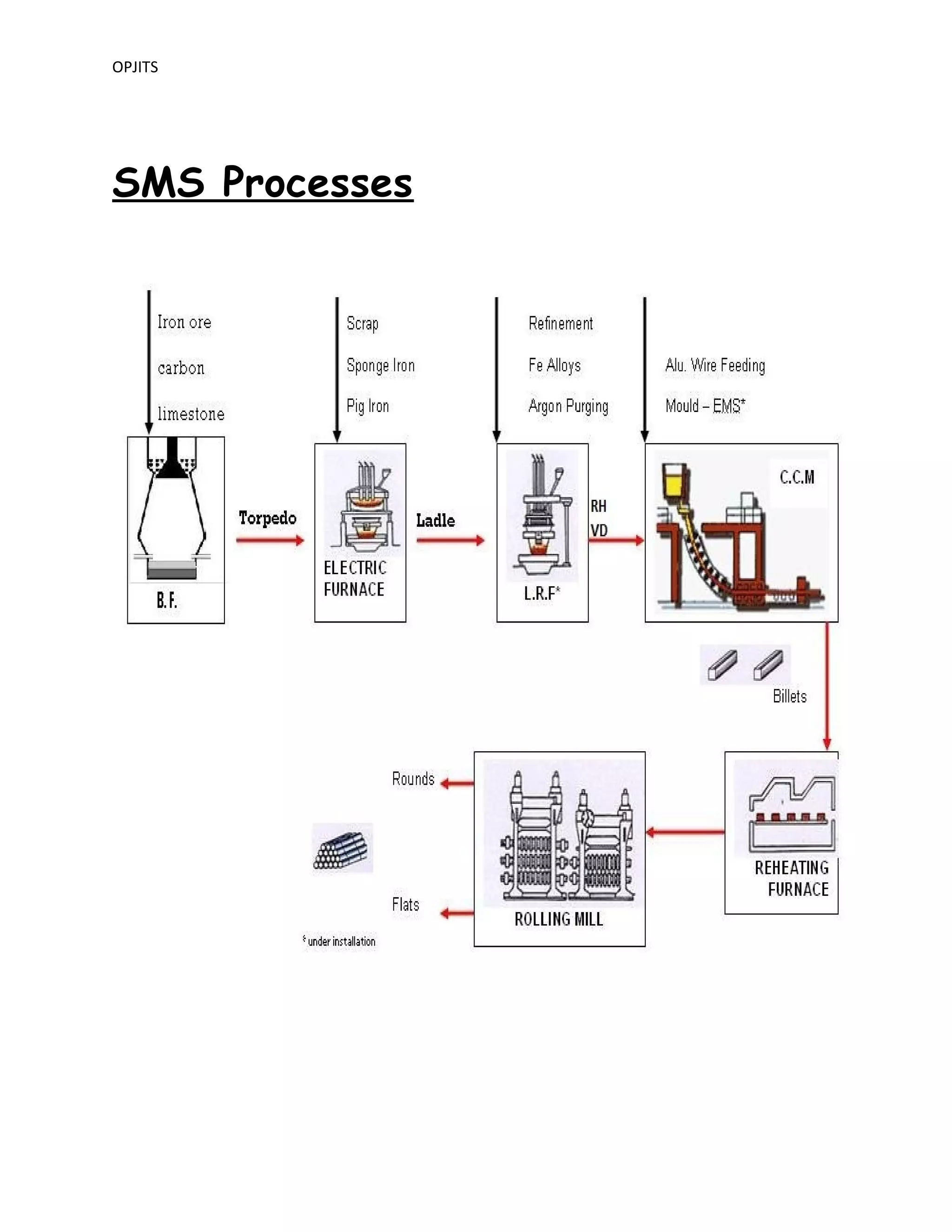

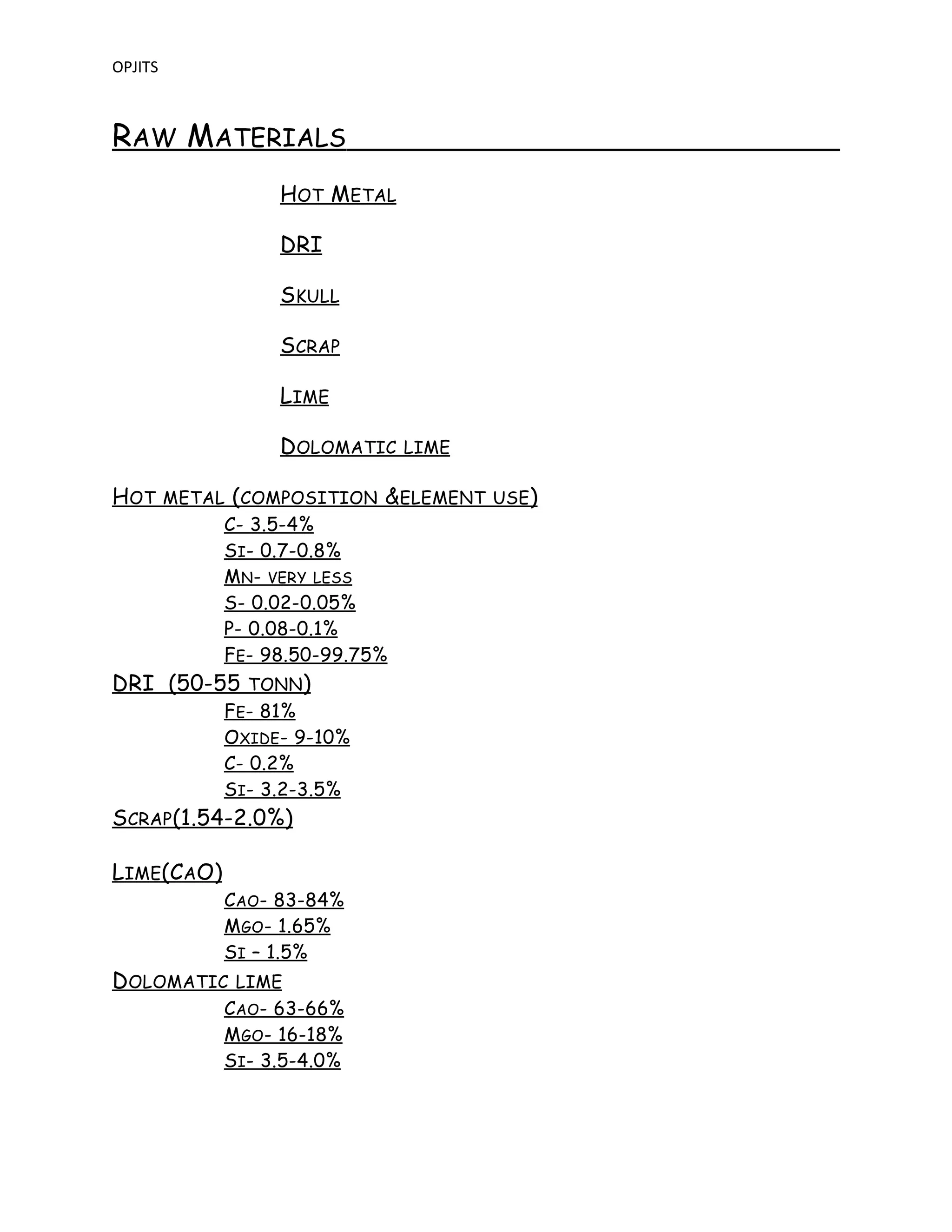

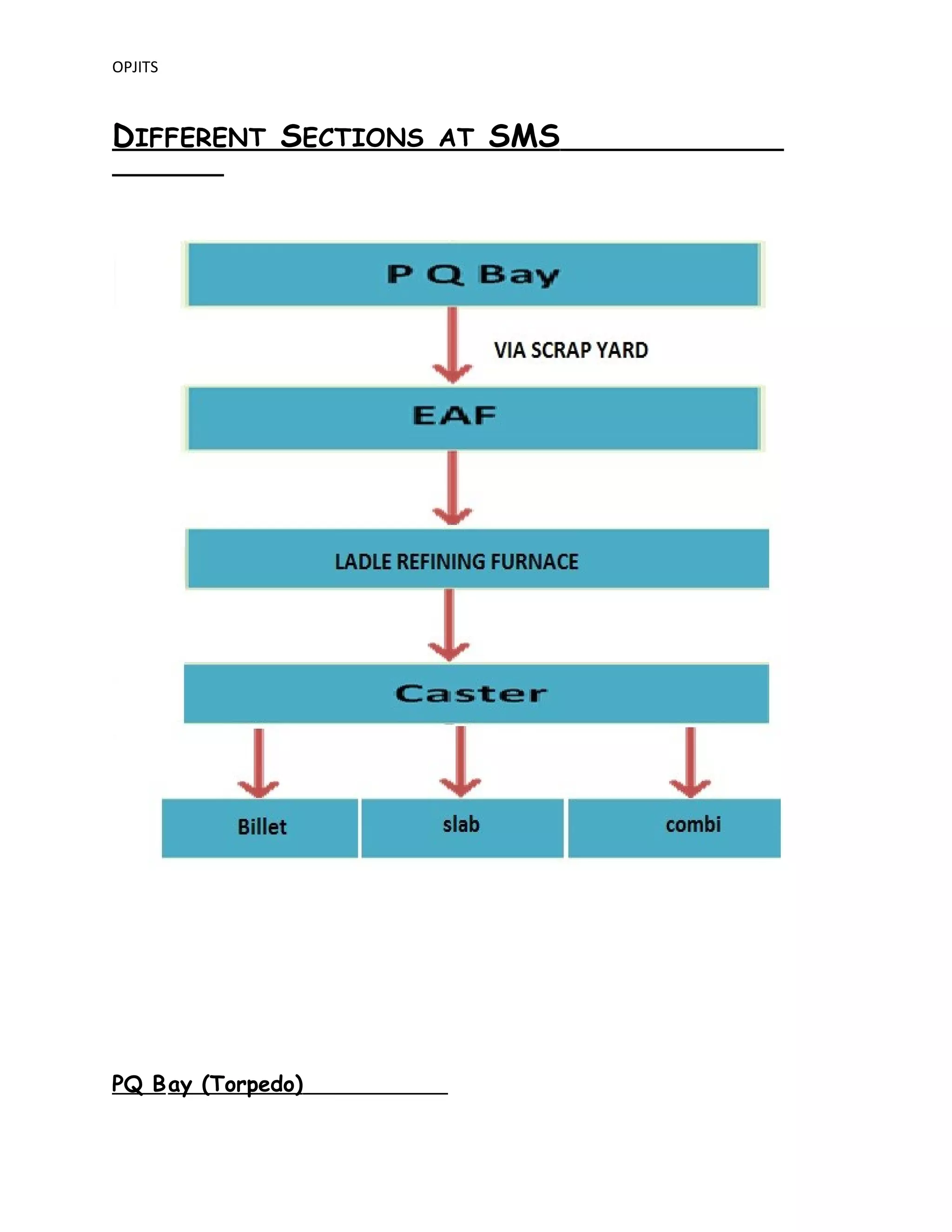

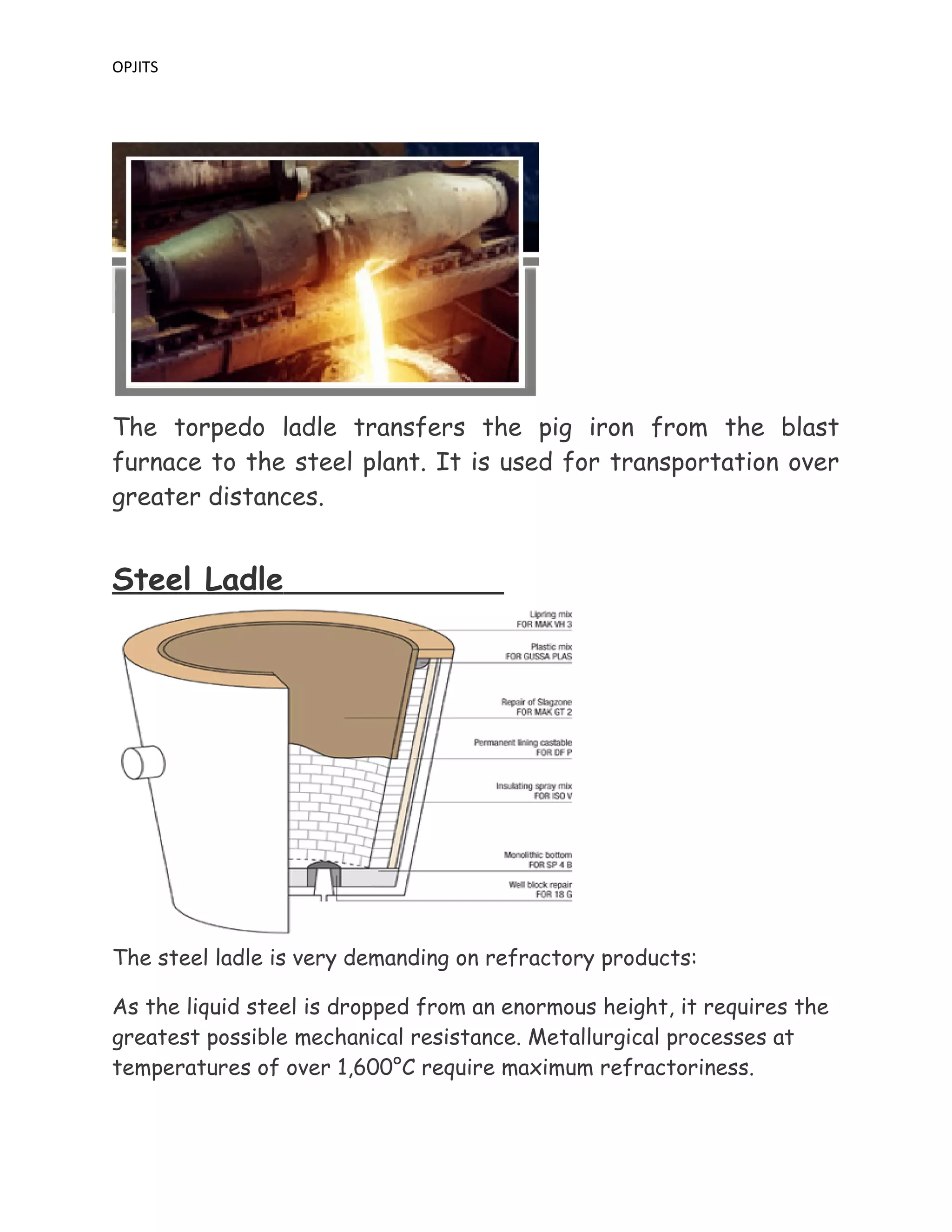

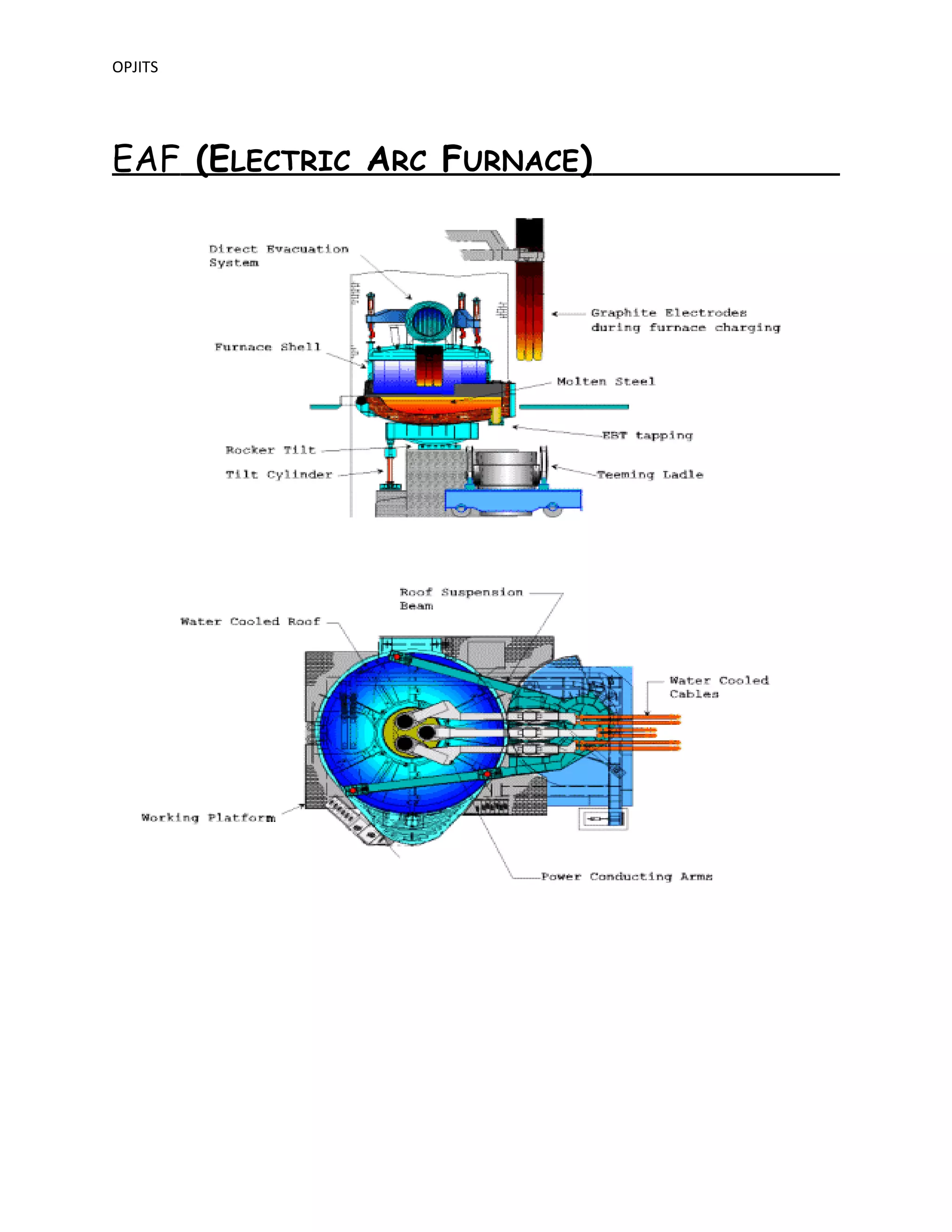

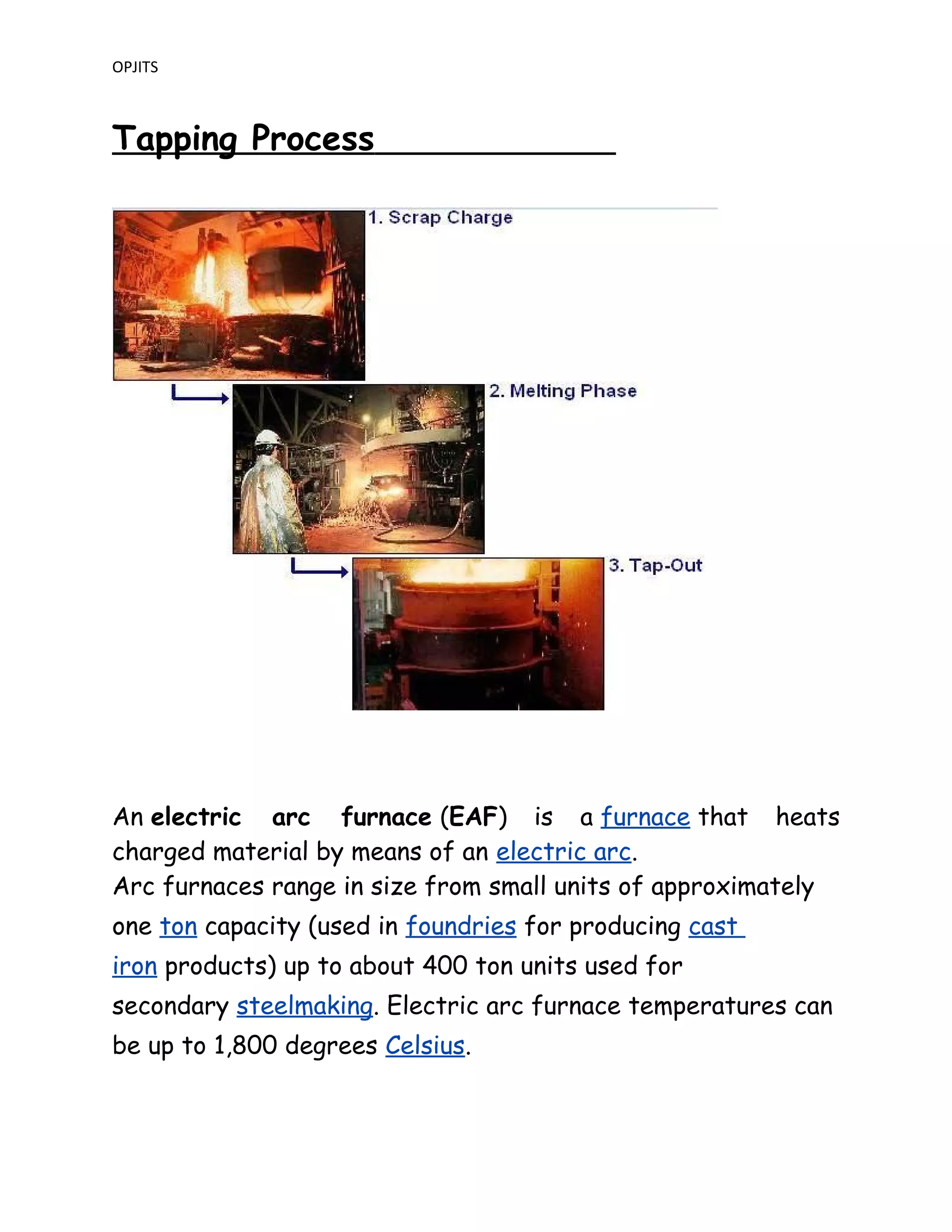

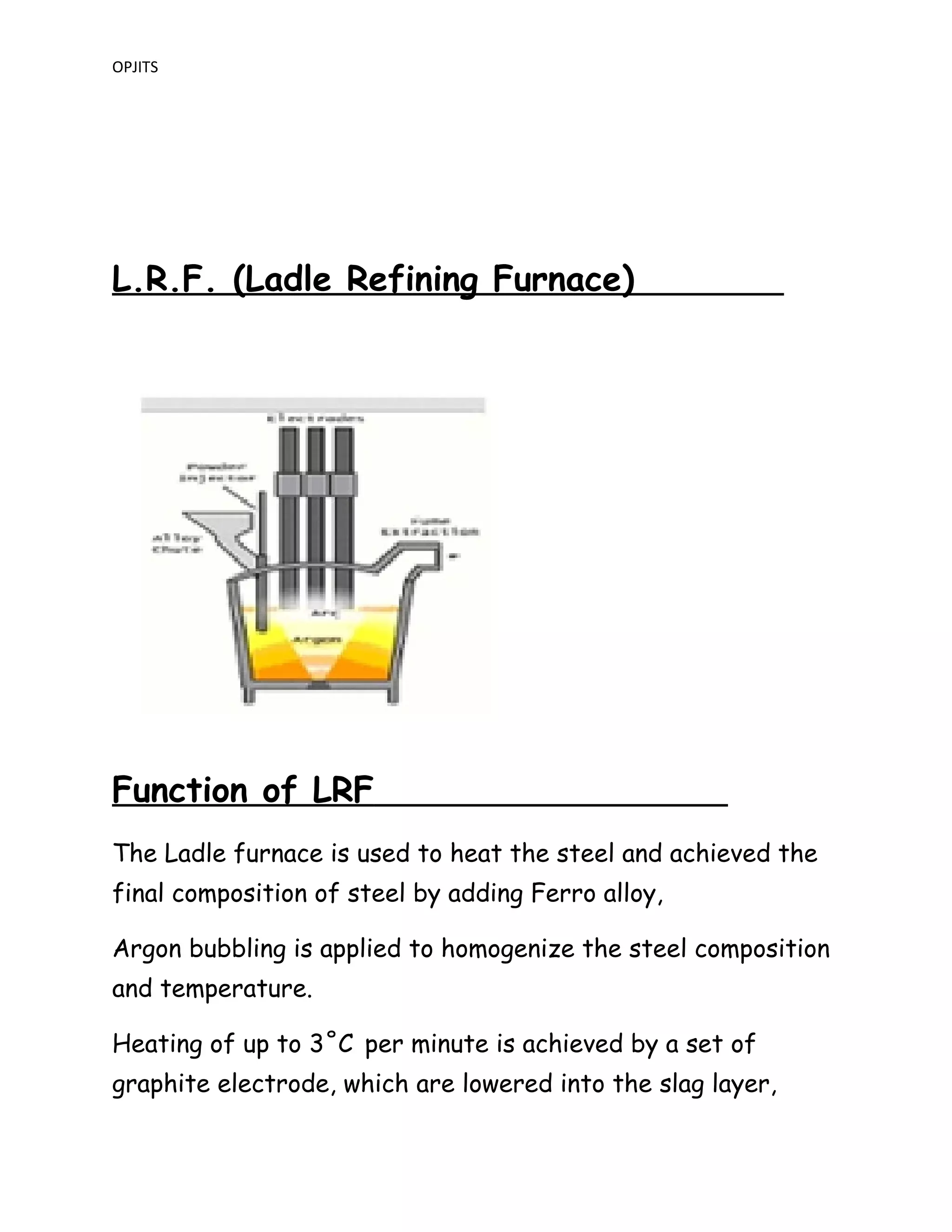

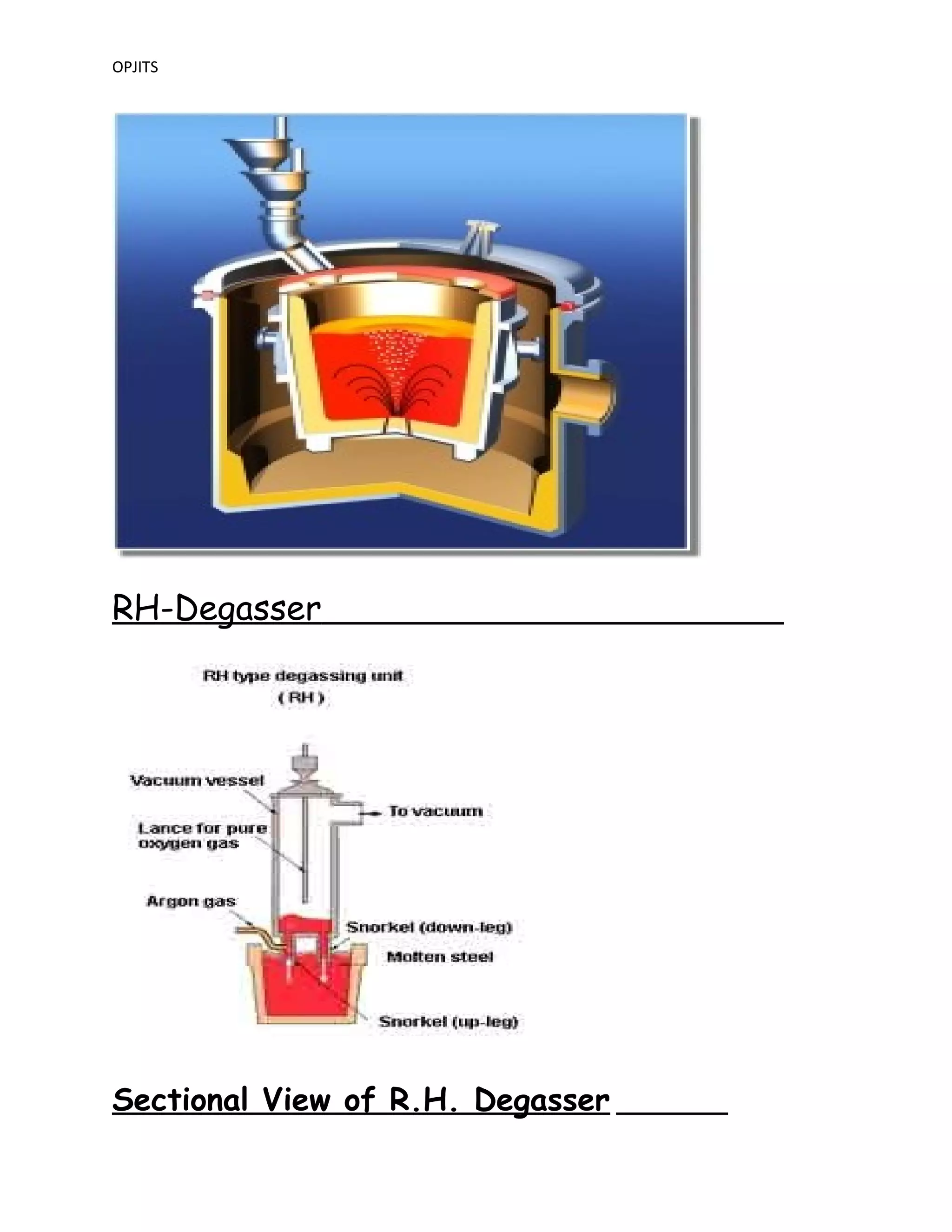

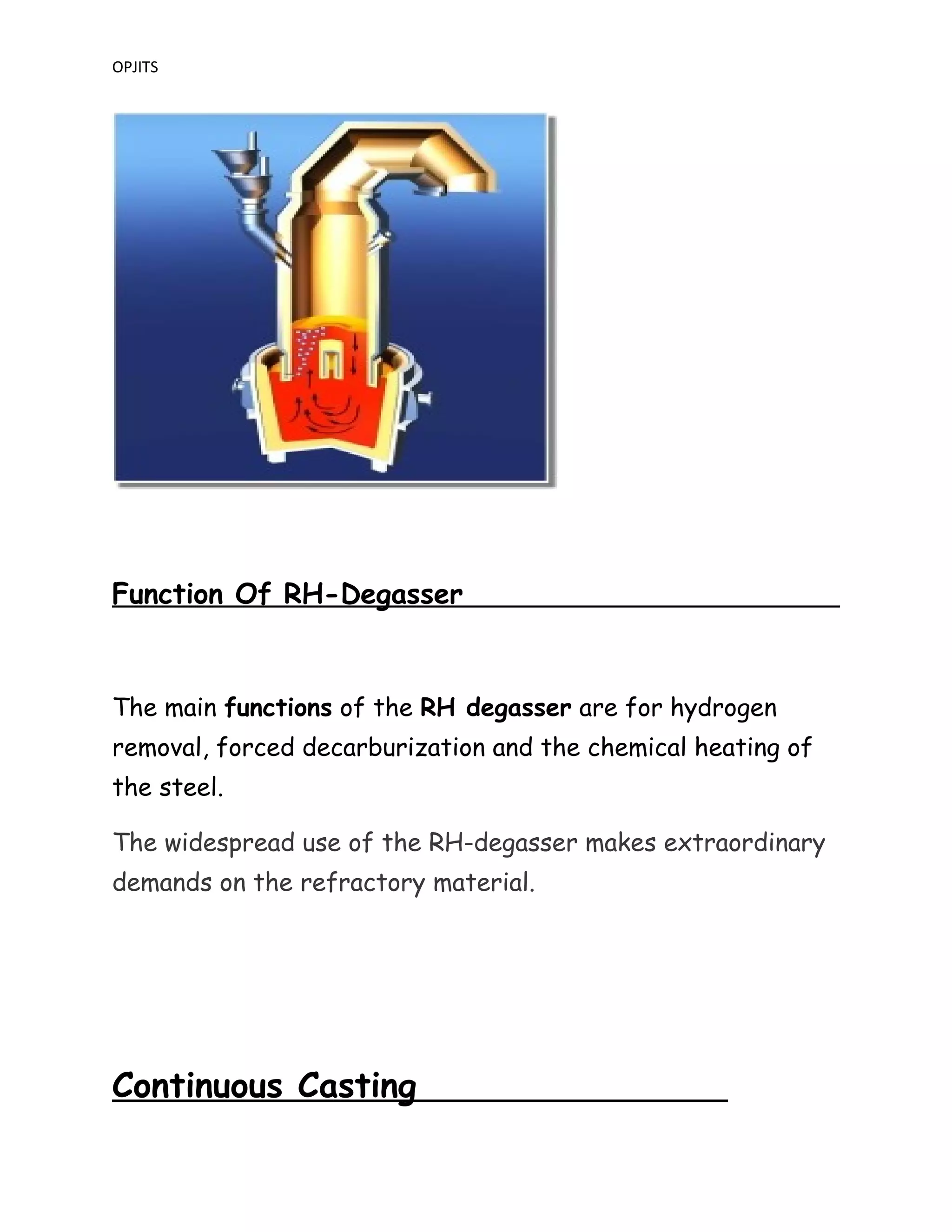

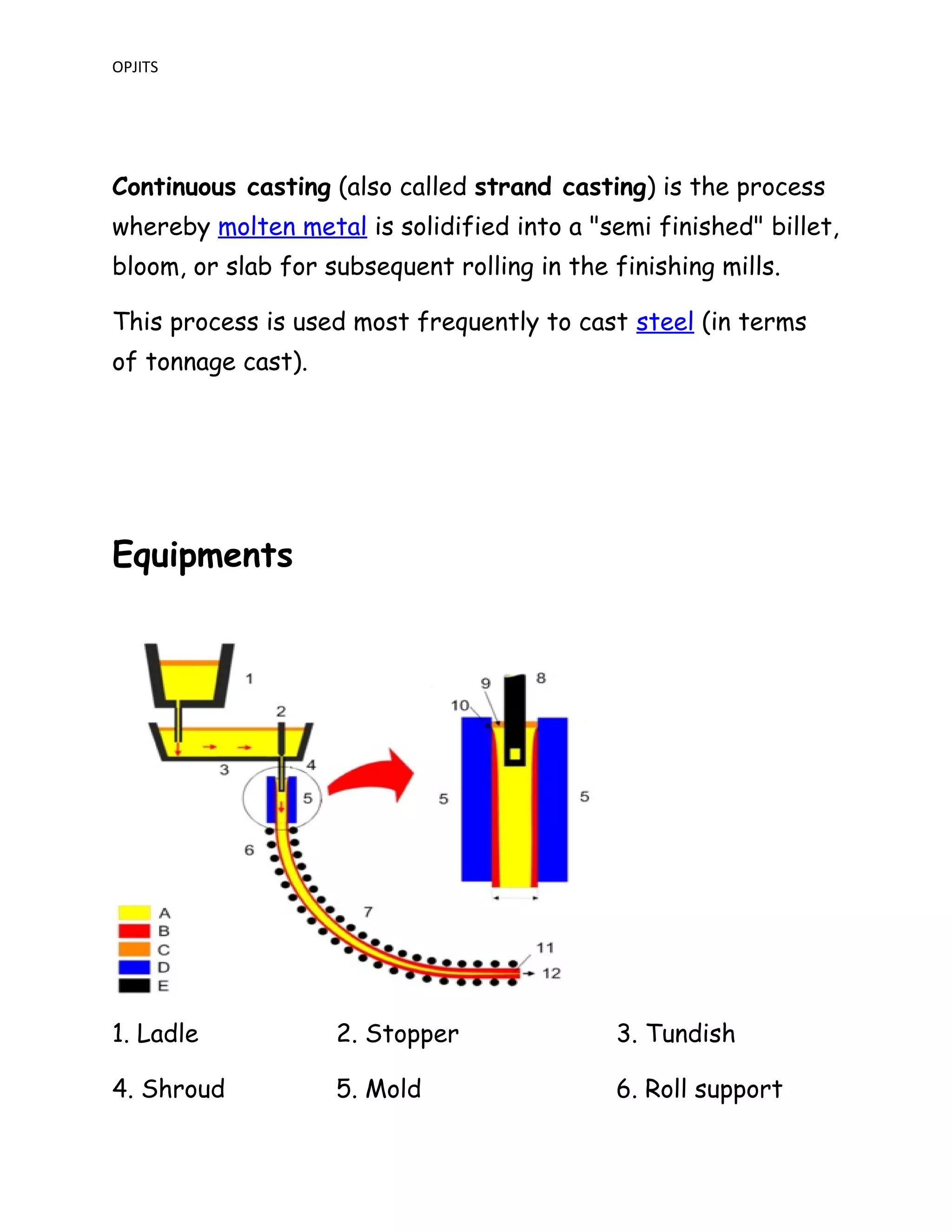

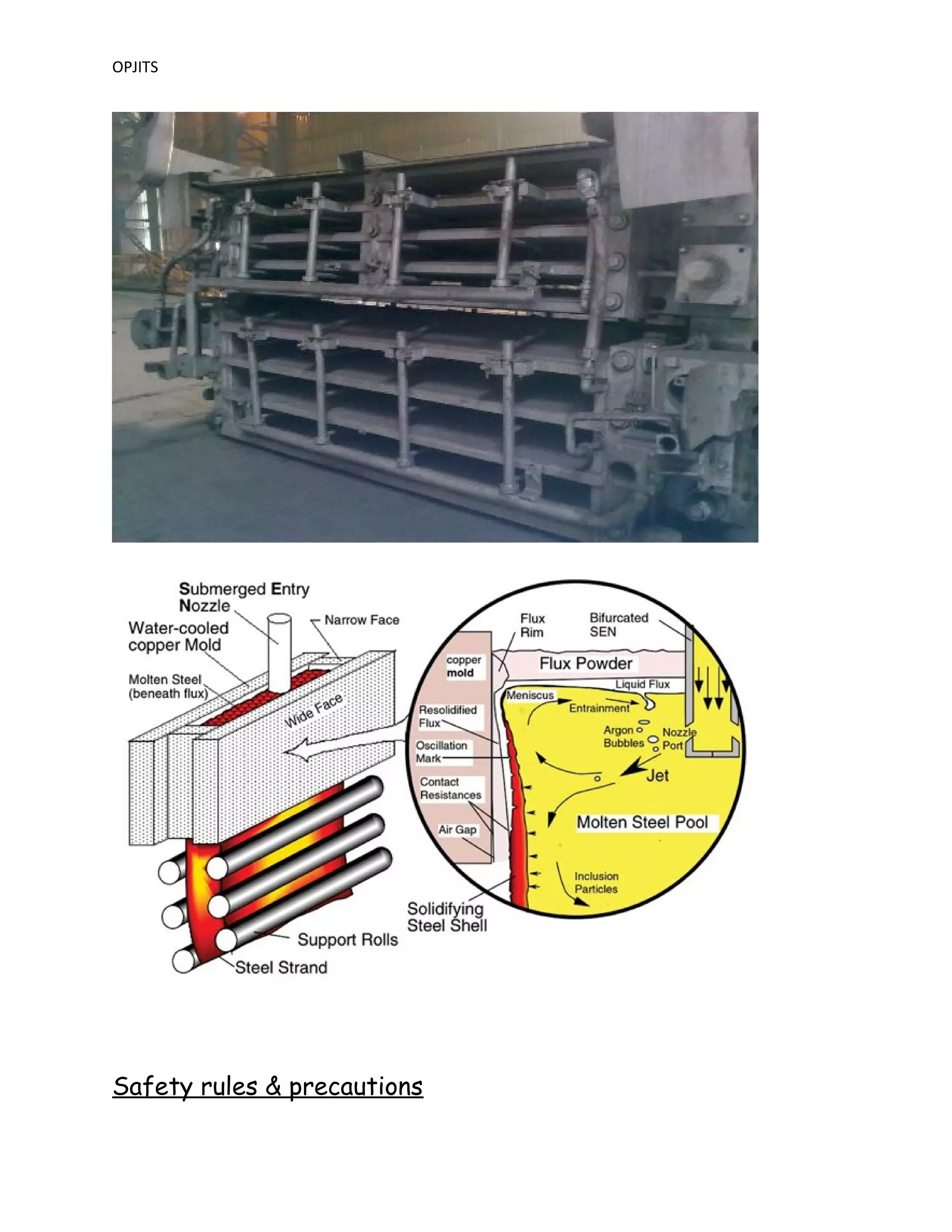

The document provides an overview of the steel melting shop (SMS) at Jindal Steel and Power Limited (JSPL). It describes the key equipment in the SMS including electric arc furnaces, ladle refining furnaces, vacuum degassing units, and continuous casters. It also summarizes the main processes like primary refining at the electric arc furnace and secondary refining at the ladle refining furnace. Safety rules and precautions for working in the SMS are highlighted at the end.