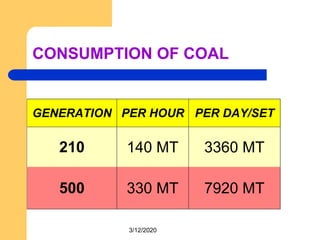

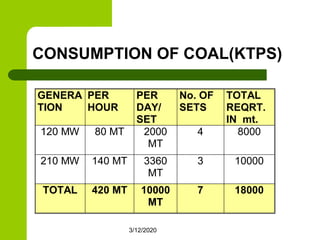

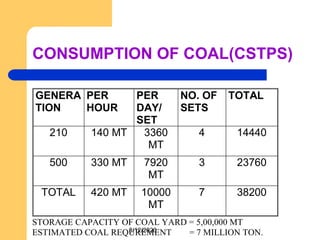

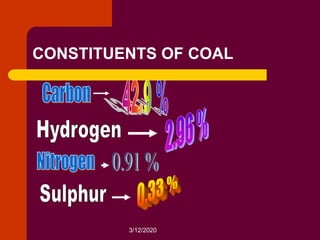

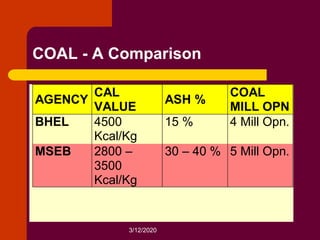

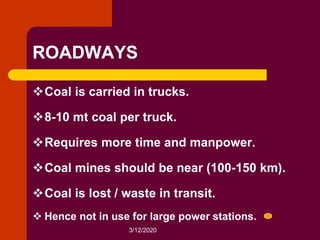

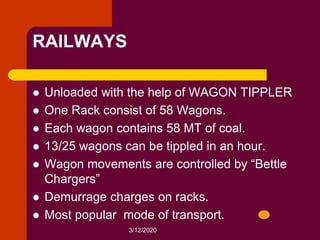

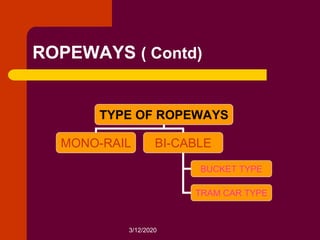

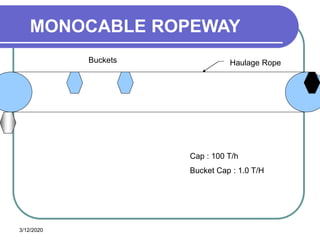

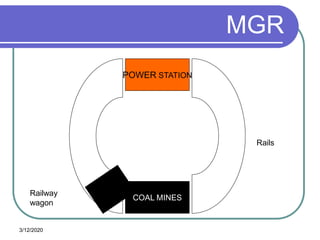

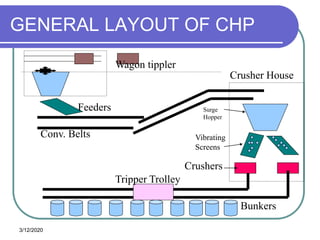

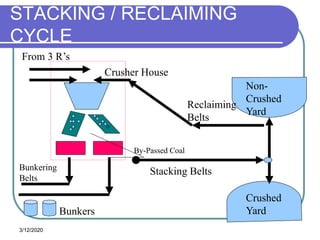

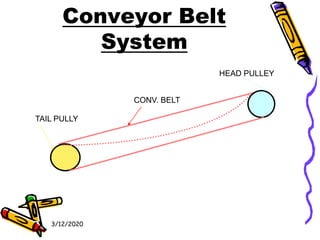

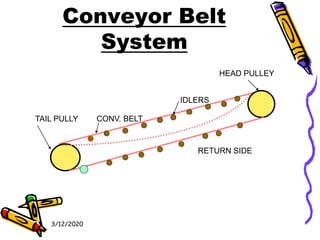

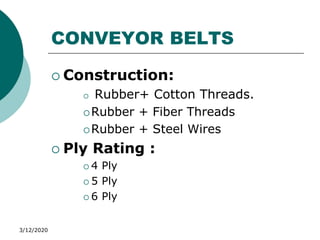

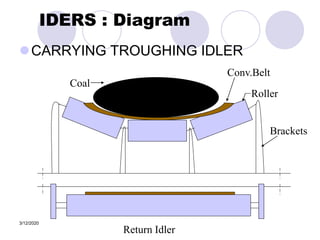

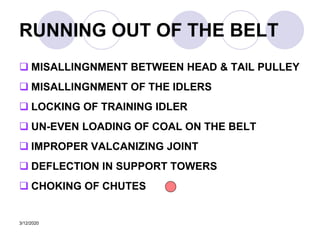

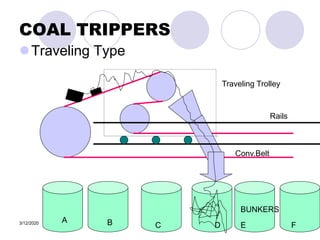

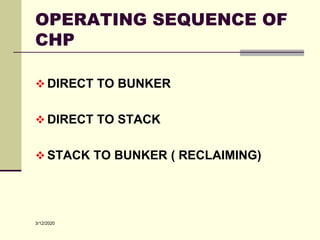

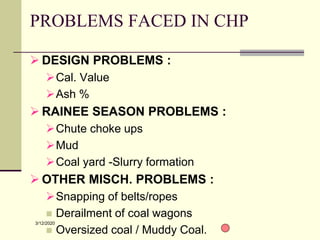

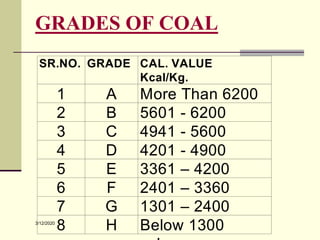

The document outlines the processes and systems involved in coal management at thermal power plants, focusing on coal consumption, transportation, and handling. It details the various means of coal transport, including roadways, railways, and ropeways, and discusses the equipment used for coal management, such as conveyors and crushers. Additionally, it highlights problems faced in coal handling processes as well as the classification of coal grades based on calorific value.