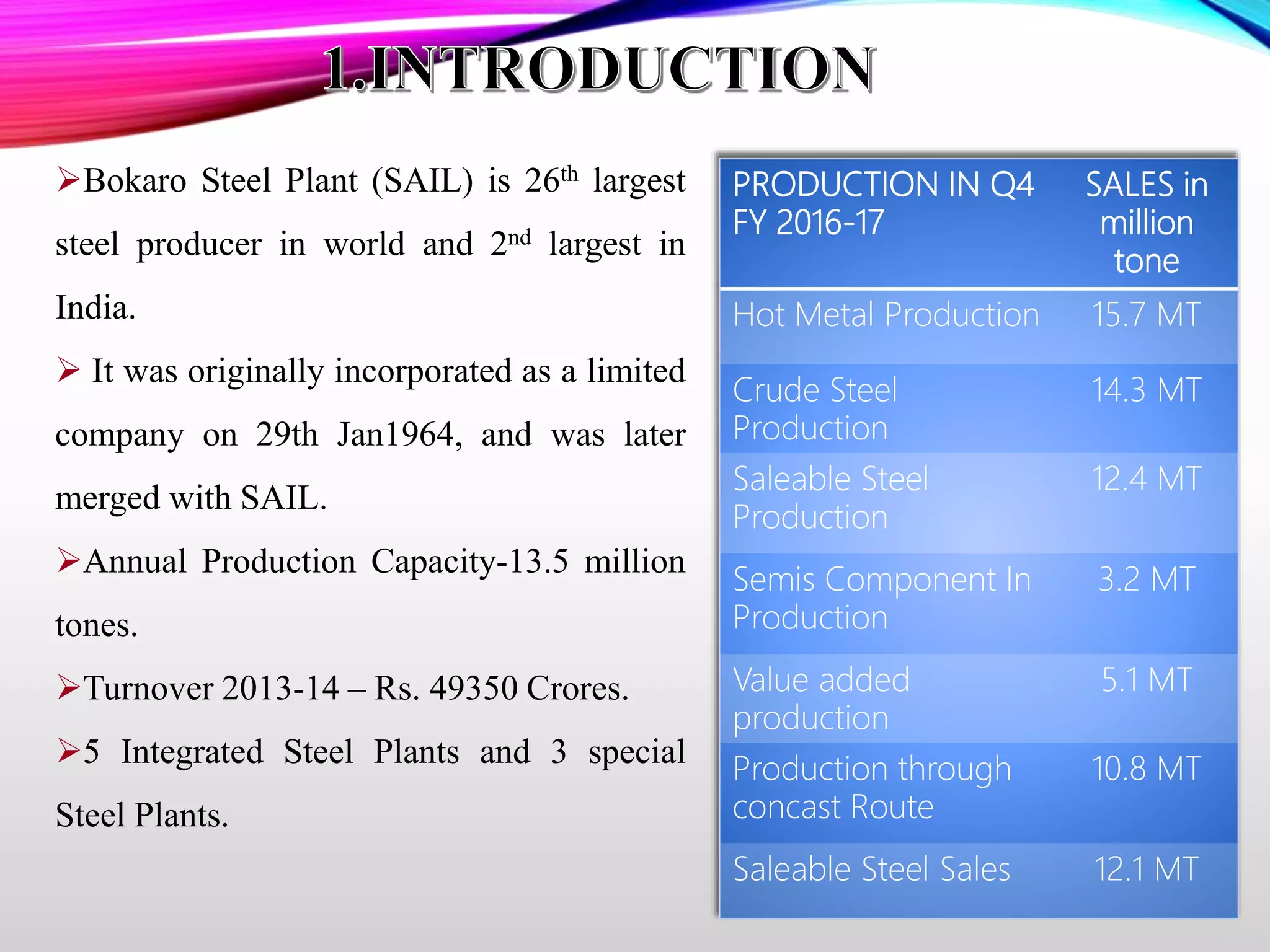

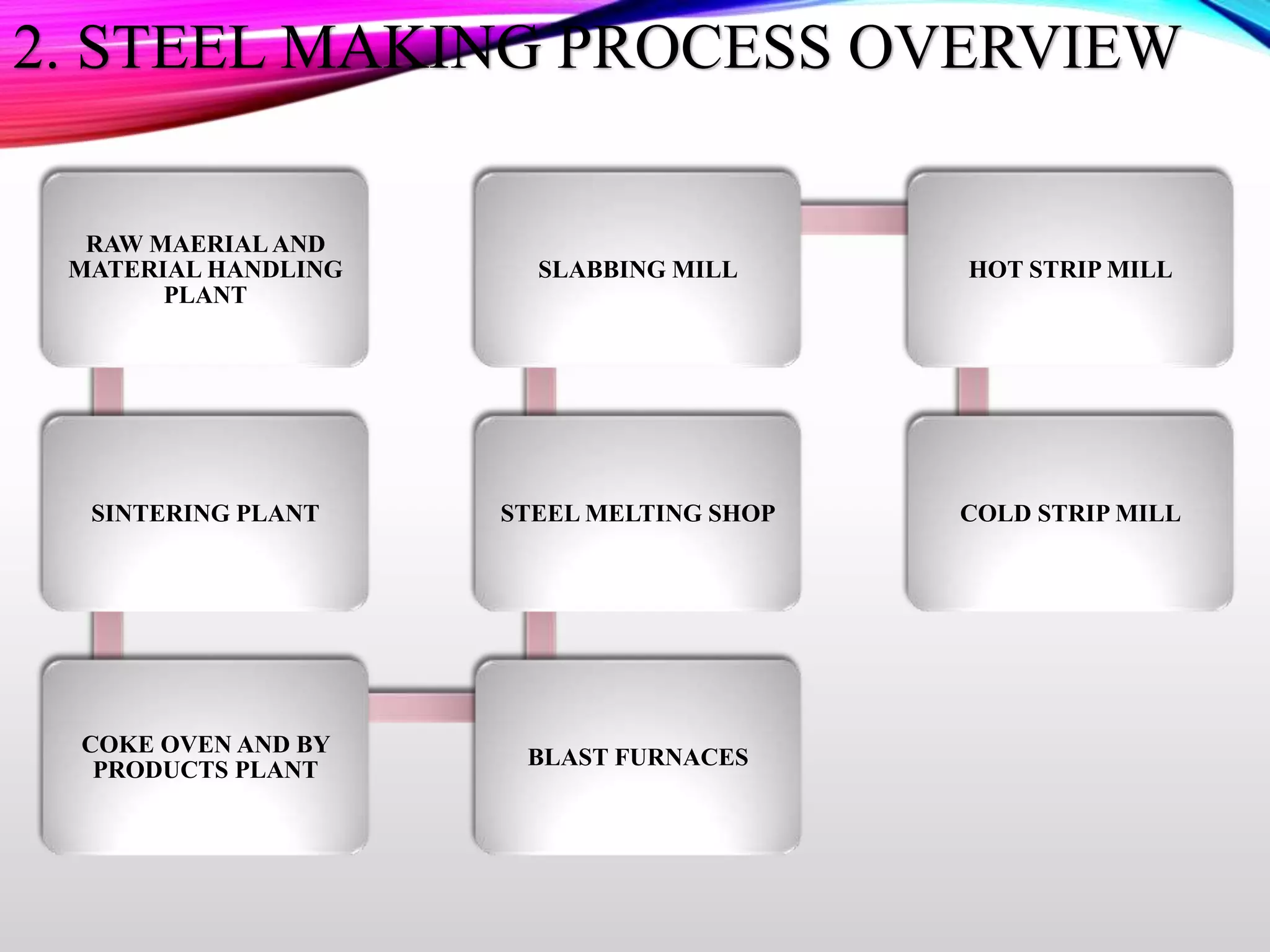

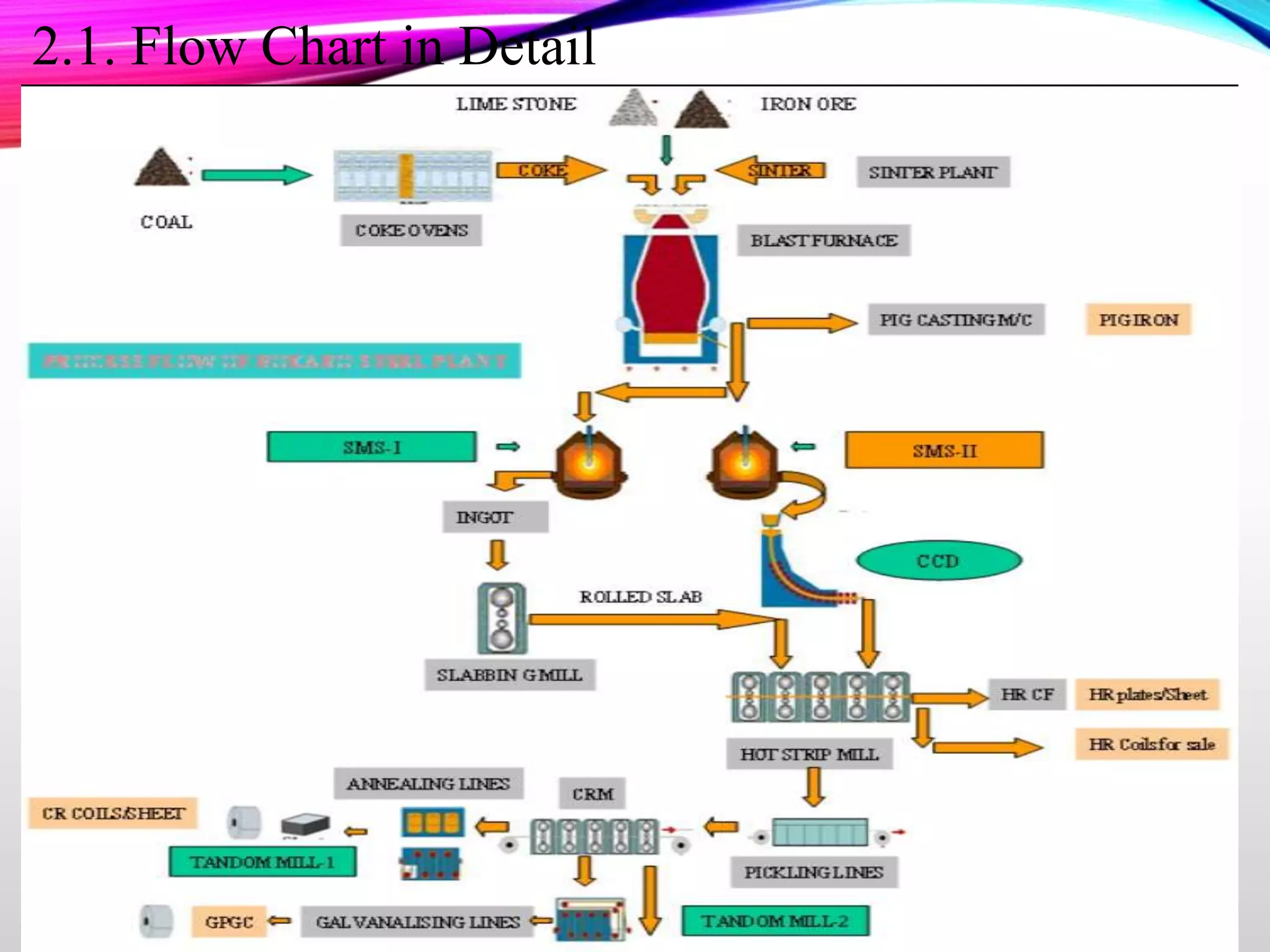

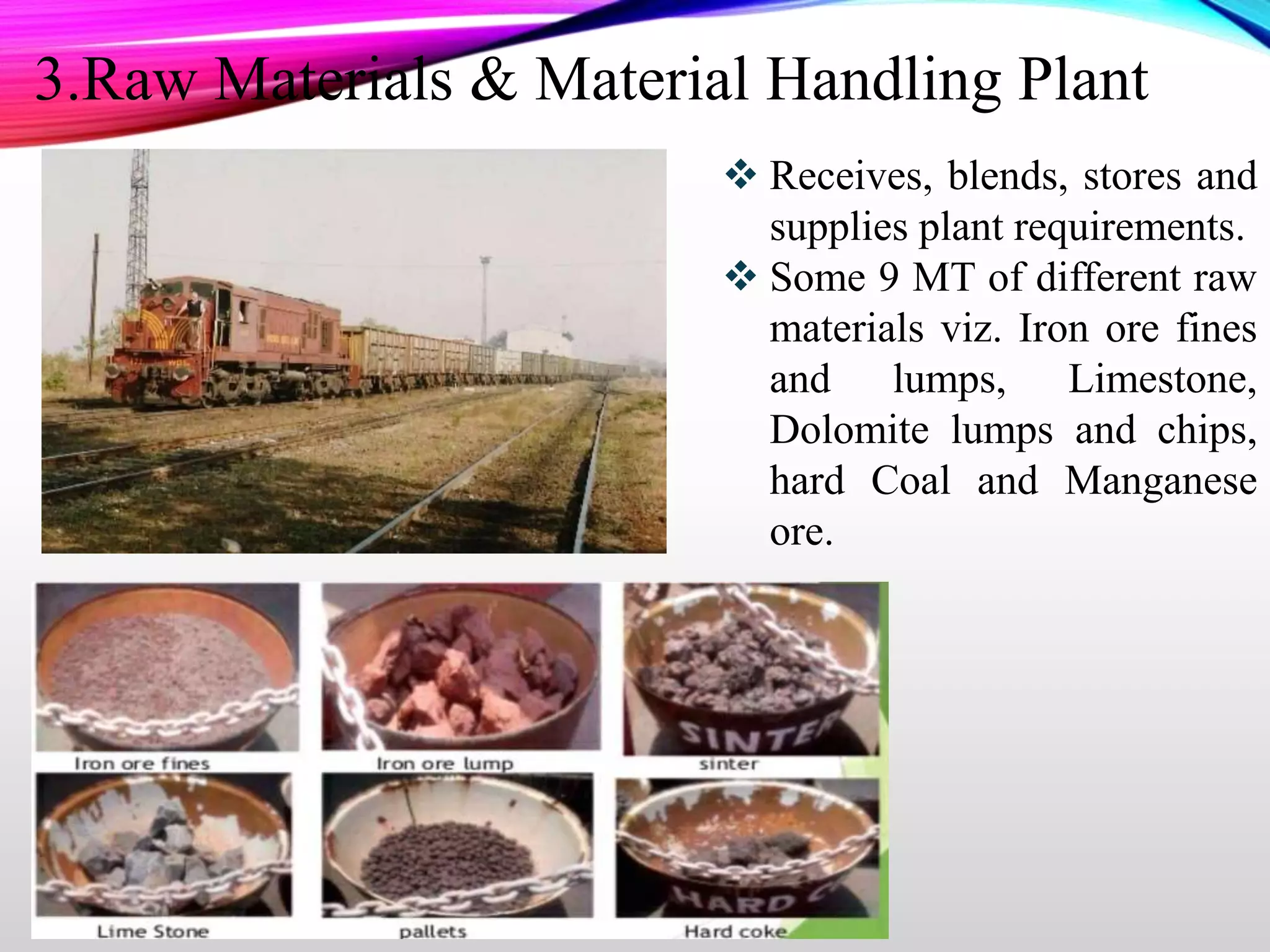

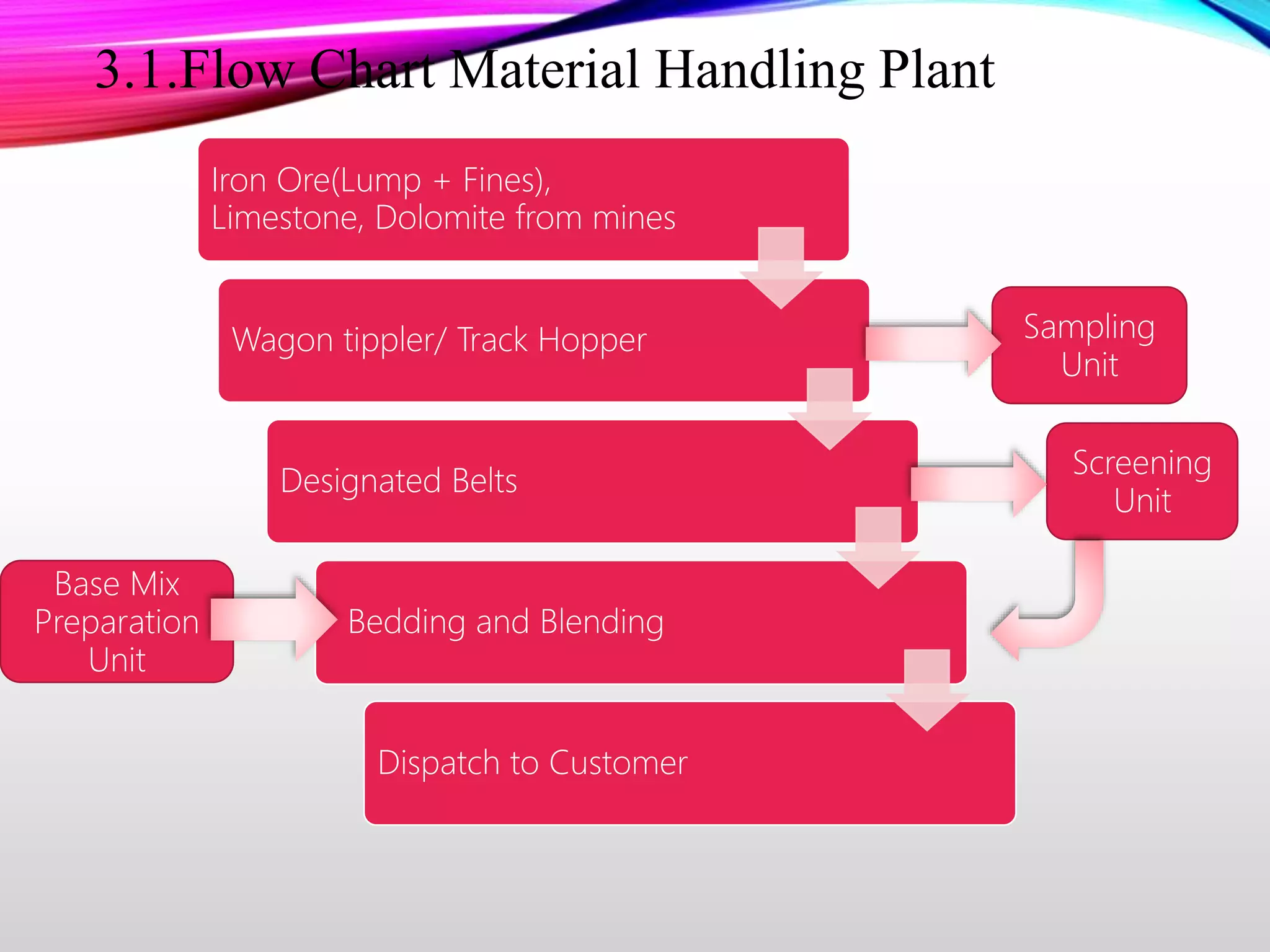

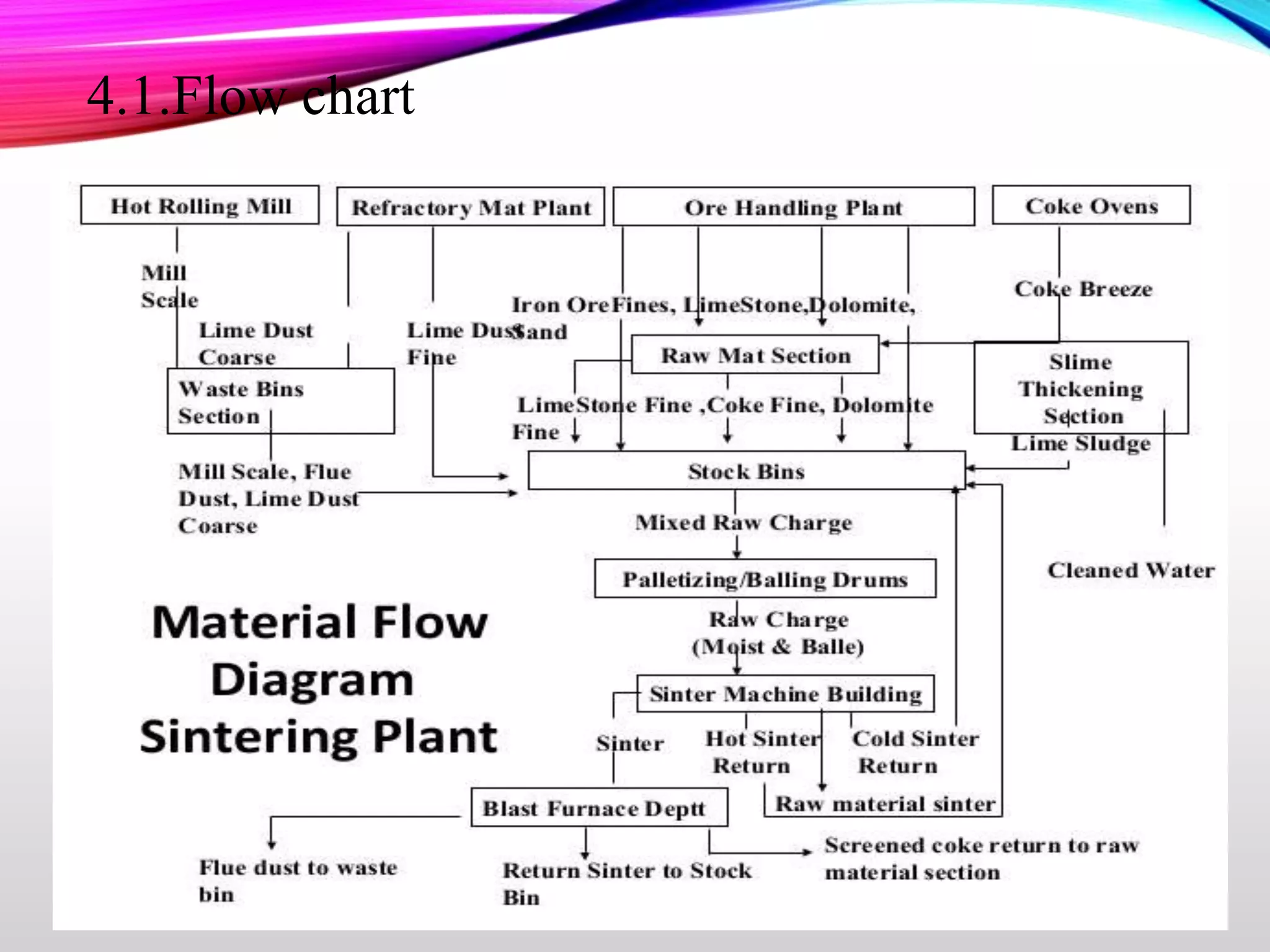

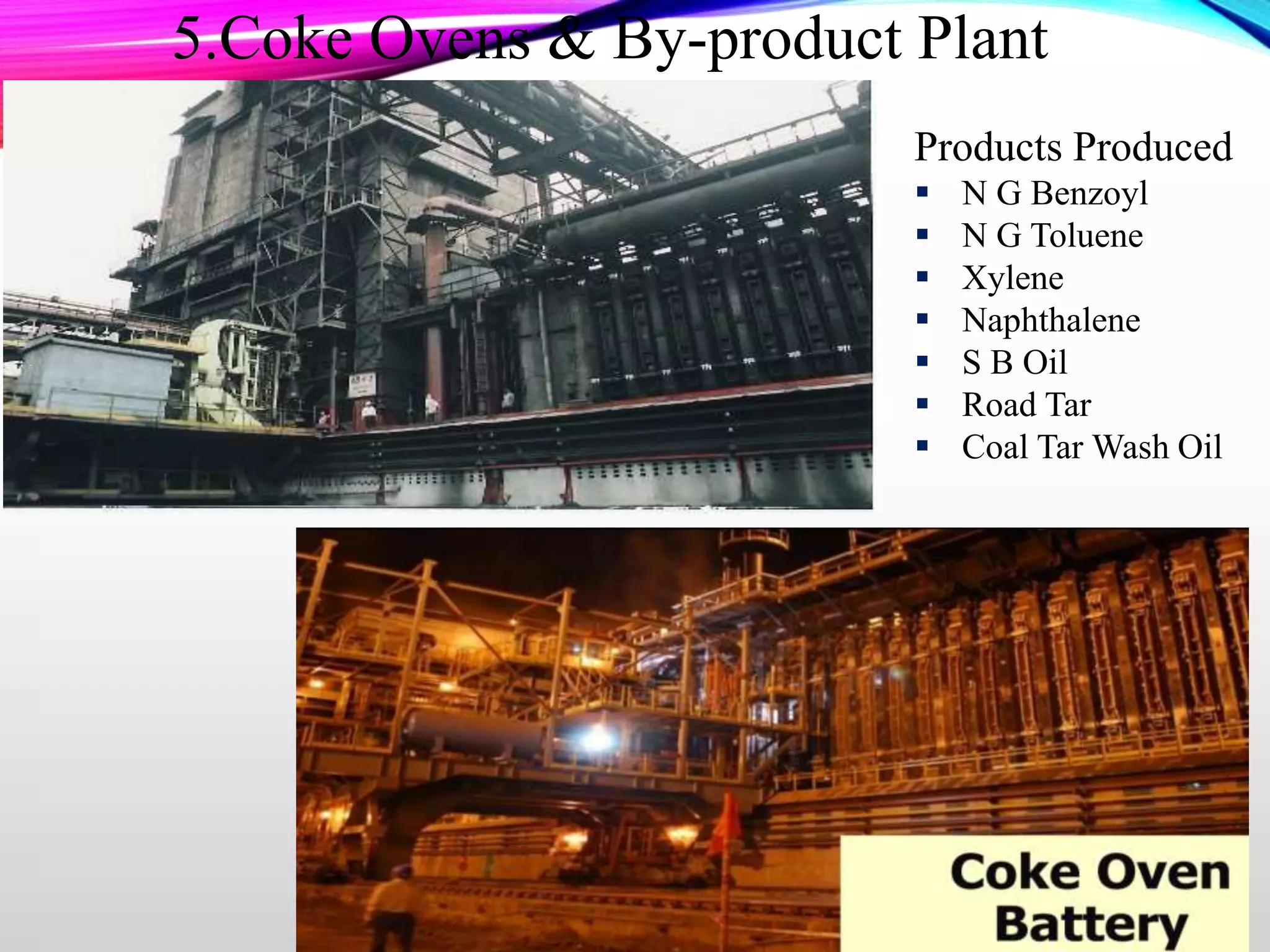

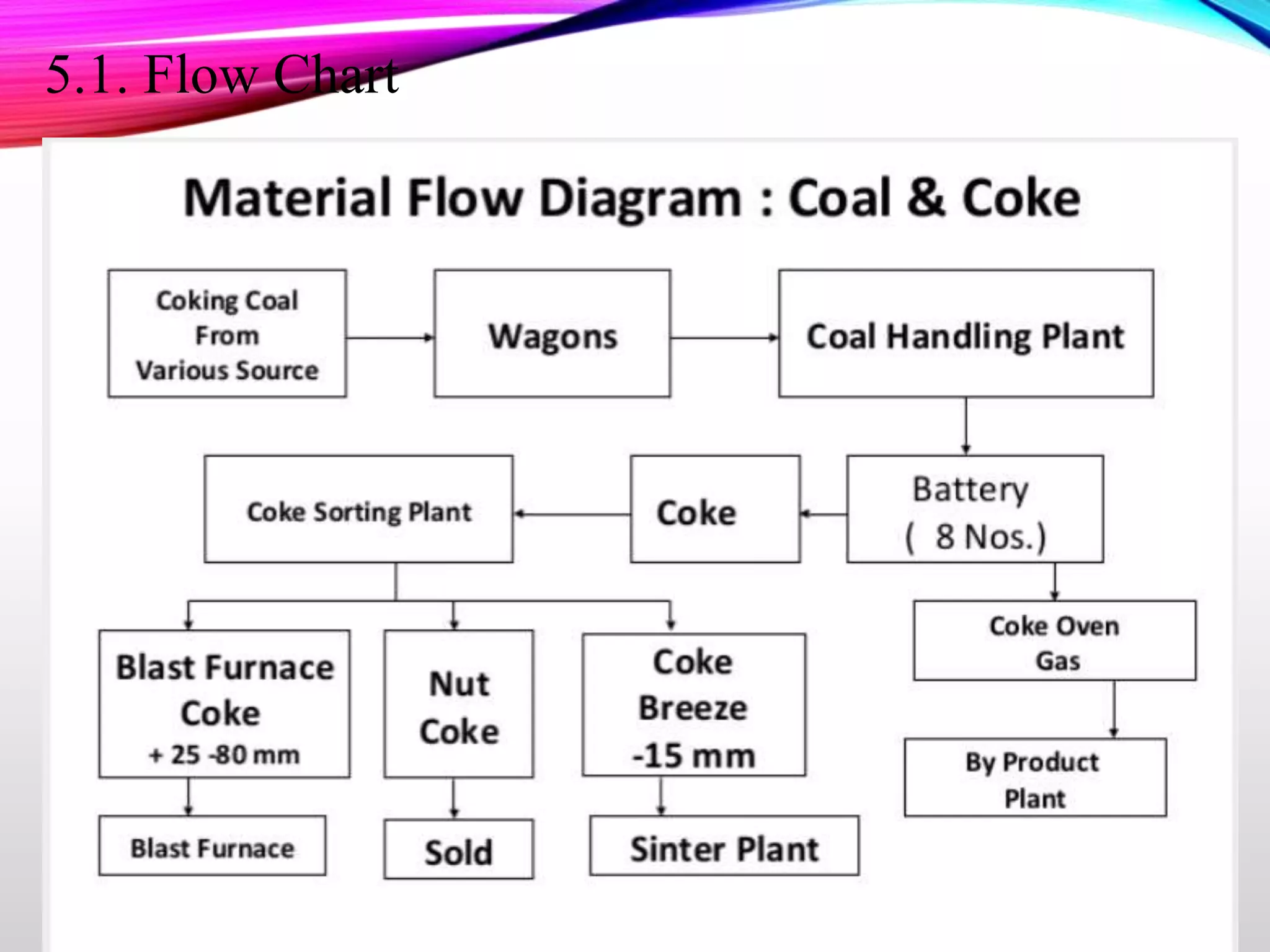

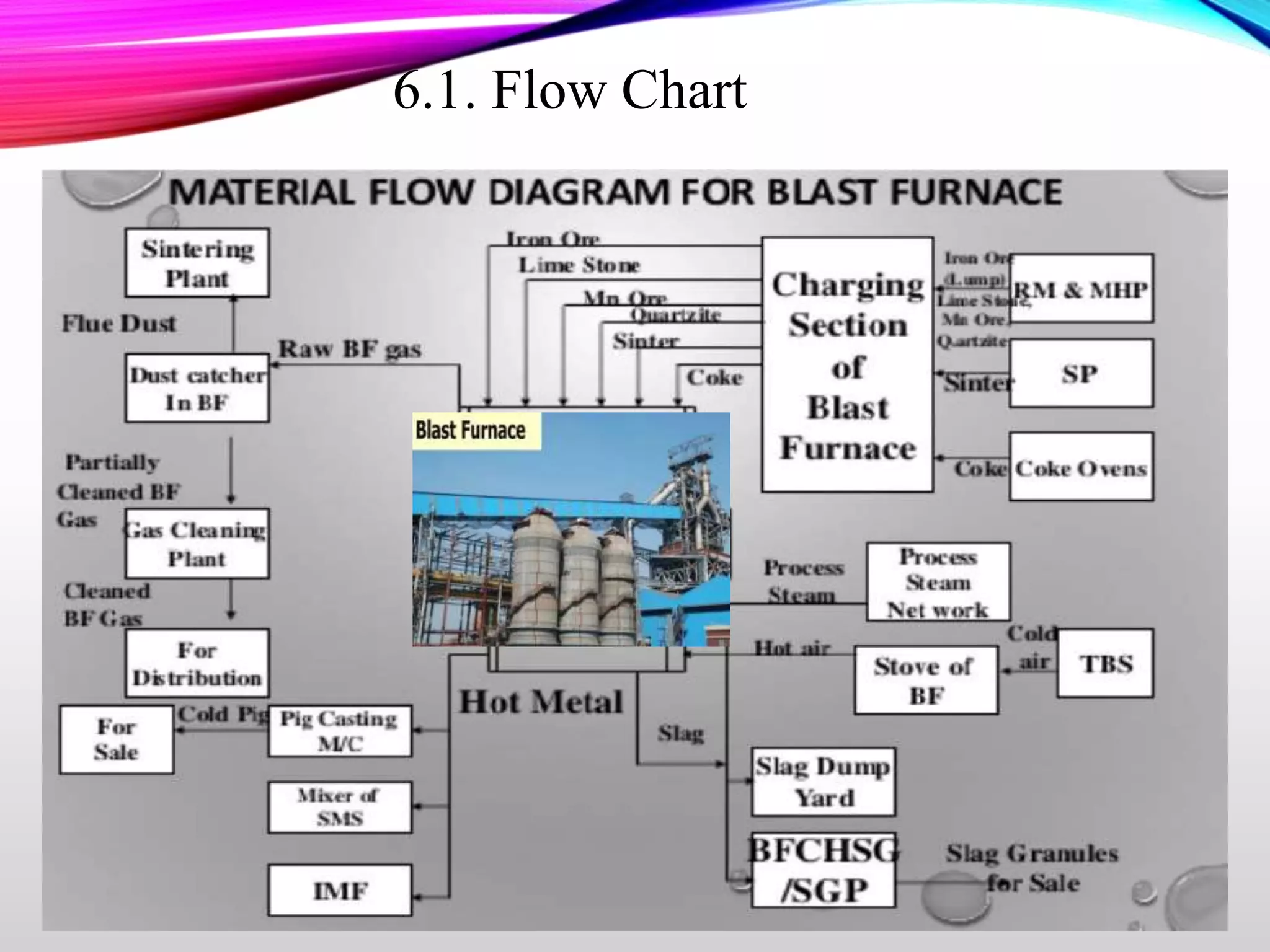

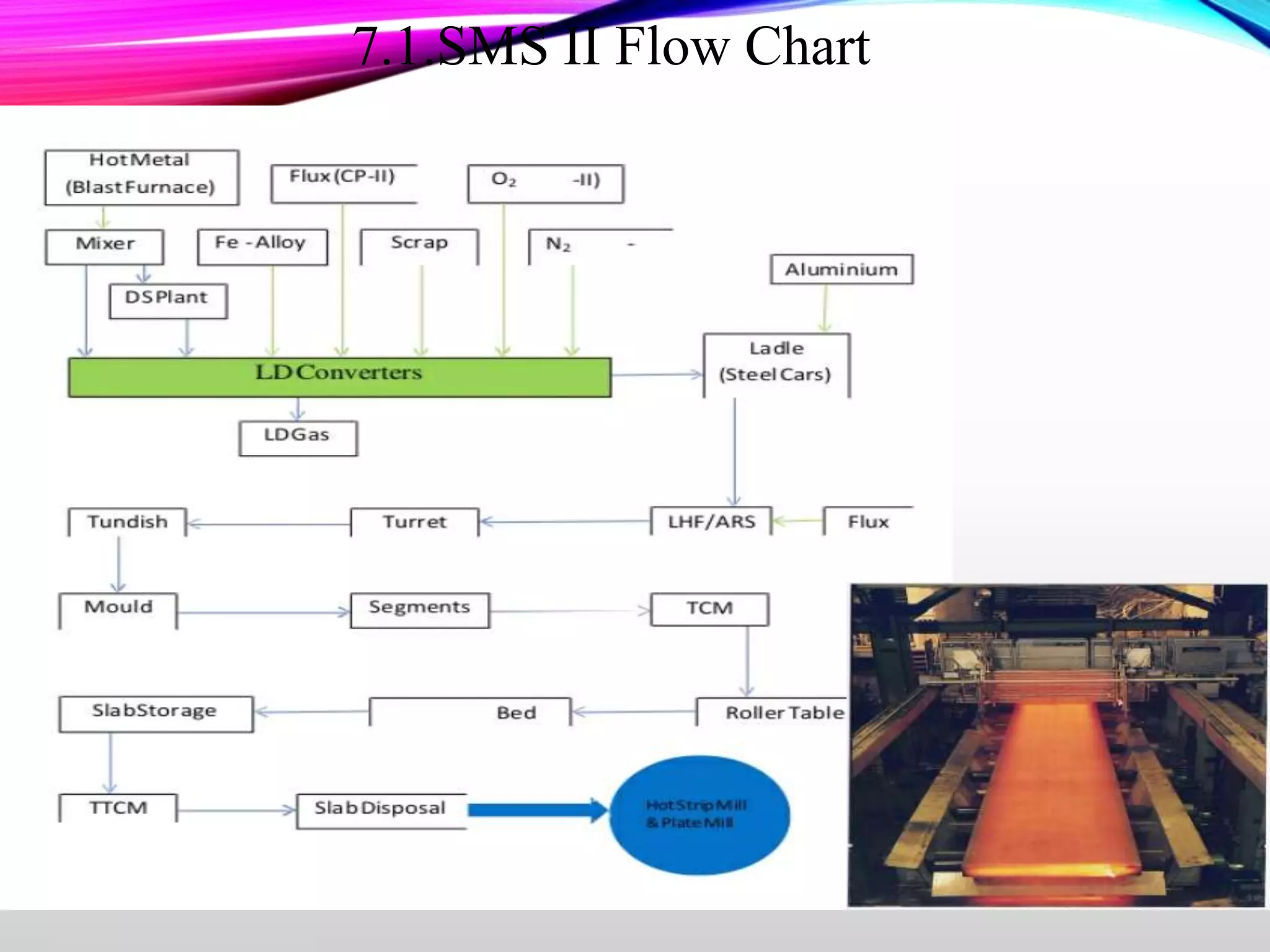

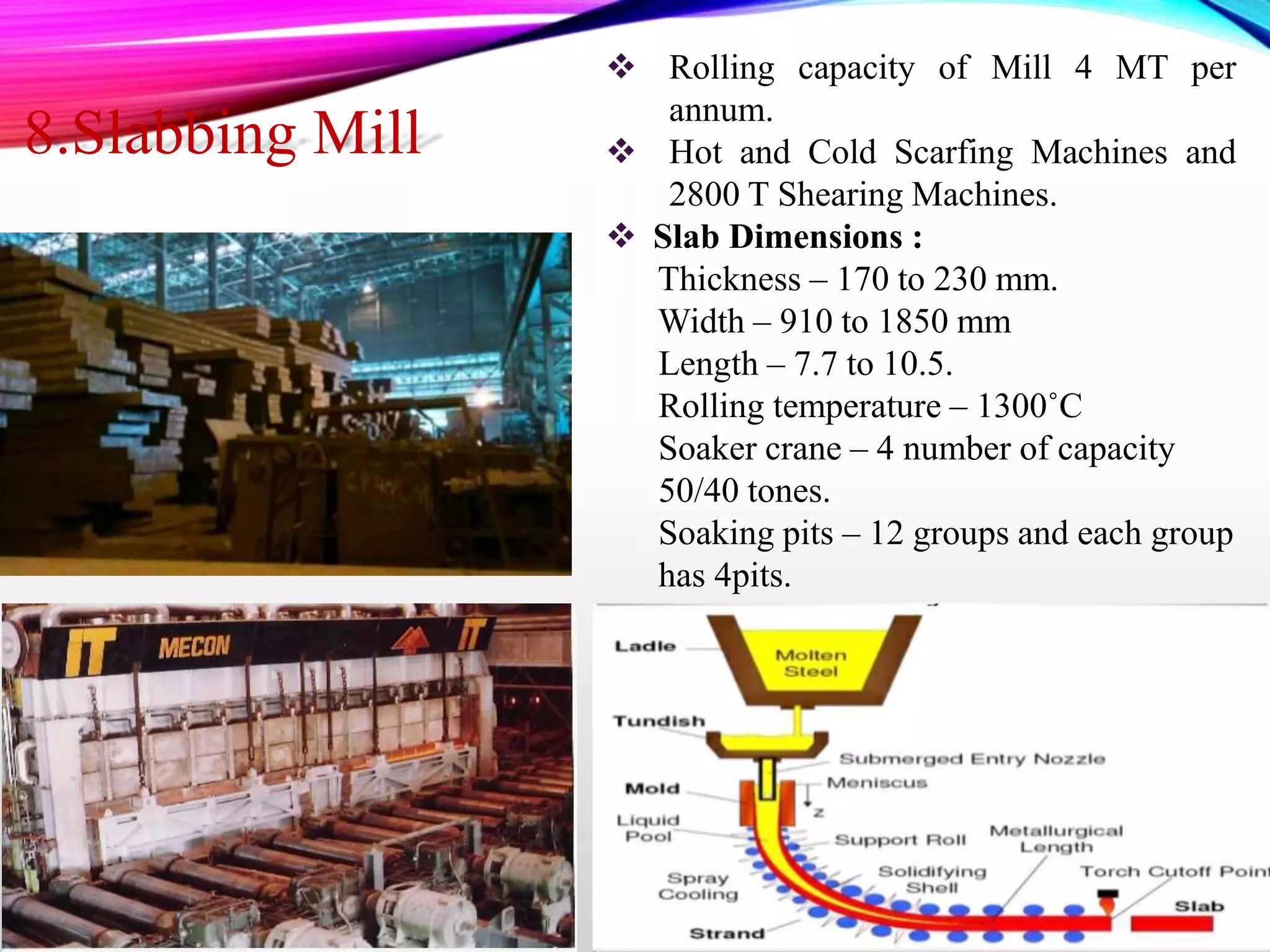

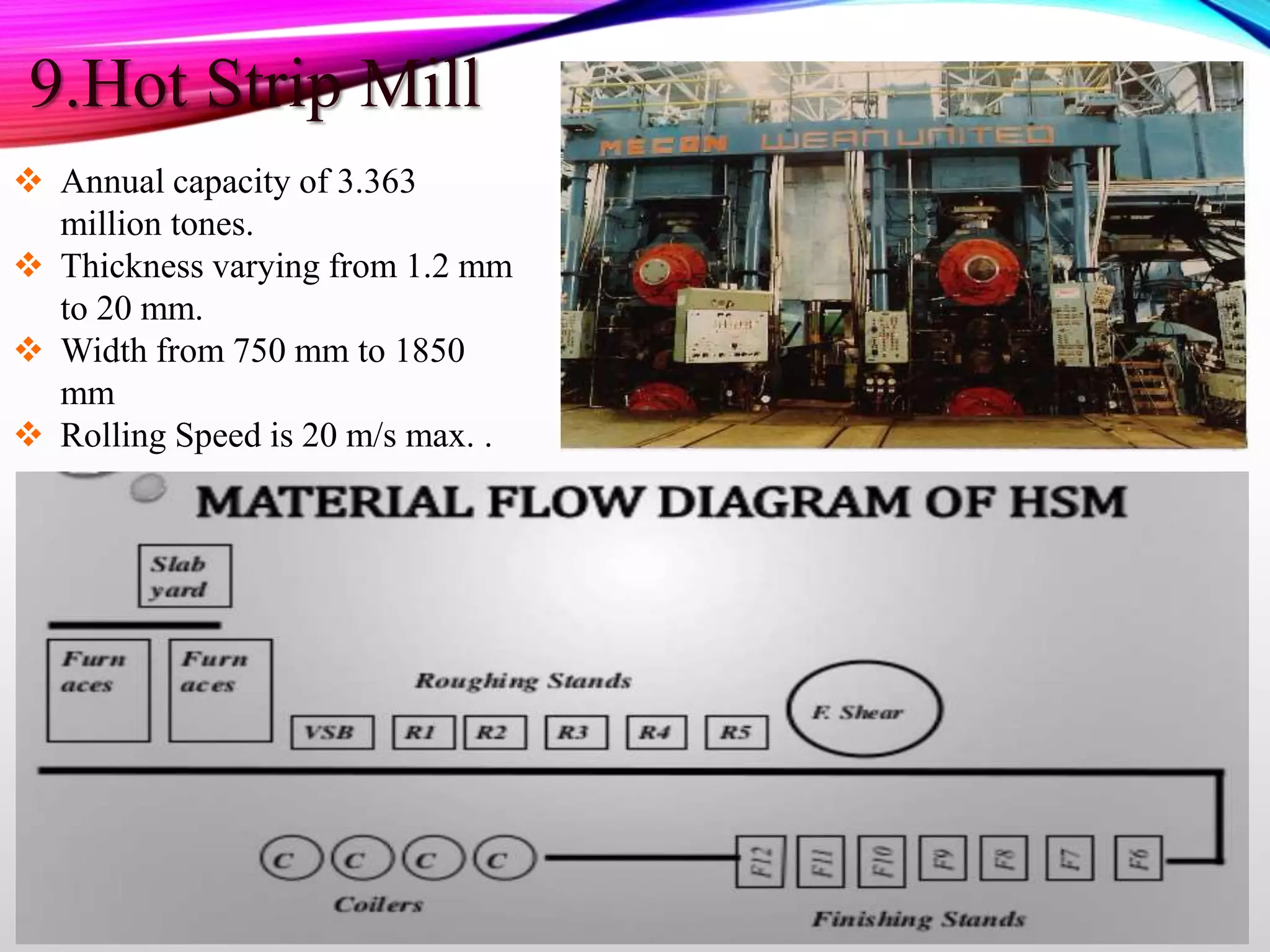

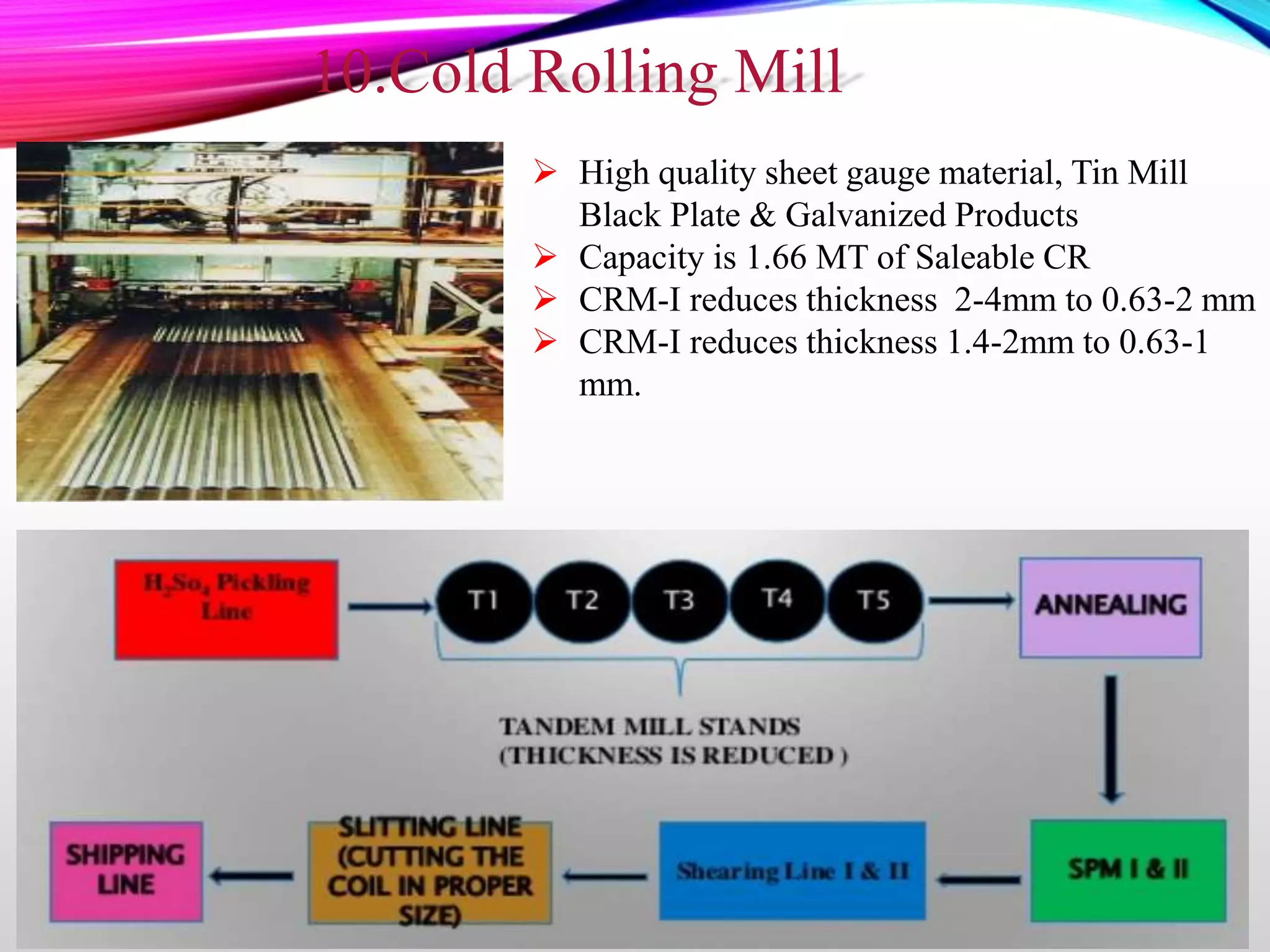

This document provides an overview of the steel production process at Bokaro Steel Plant in India. It describes the key steps: raw material handling and preparation, sintering, coke production, blast furnaces, steel melting, slab production, hot and cold rolling, and finished products. The plant has an annual production capacity of 13.5 million tons and produces a range of steel products through continuous modernization and expansion projects.