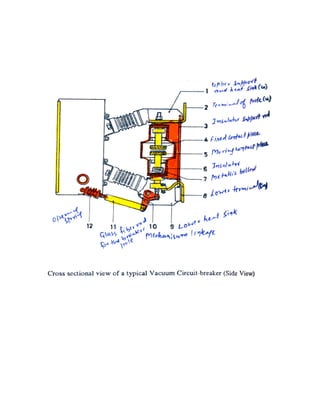

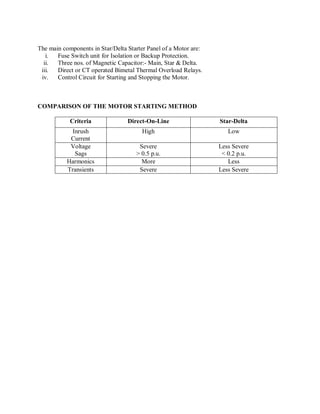

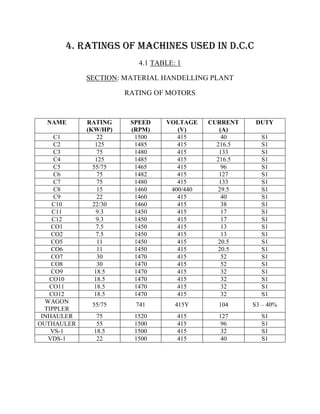

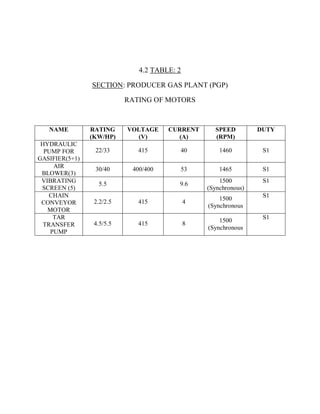

The document provides details about Kumar Saurabh's one month vocational training at Dankuni Coal Complex operated by South Eastern Coalfields Limited. It includes an acknowledgement, preface, contents, and sections describing the brief history of DCC, its various sections like power distribution, material handling, producer gas plant, and utilities. It also includes a brief introduction to induction motors, ratings of machines used at DCC, troubleshooting, and a conclusion. The document appears to be Kumar Saurabh's technical report summarizing his experience and learnings from the vocational training.