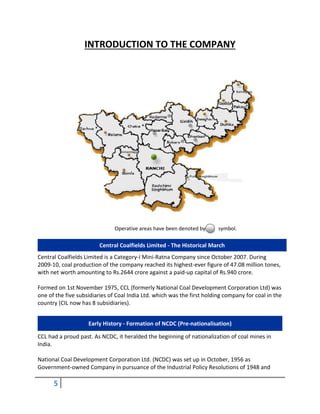

This document provides details about the Giridih Open Cast coal mining project operated by Central Coalfields Limited in Jharkhand, India. It includes an overview of the company, site-specific production targets and equipment. The mine utilizes shovel and dumper combinations to extract 2.5 lakh tonnes of coal per year from the Jatkuti seam. Equipment on site includes shovels, dump trucks, dozers, drills and water sprinklers. Statutory requirements for open cast mining as well as details on benches, spoil banks and dumps are also outlined. Maps show the layout of the mining area and additional information provides the stripping ratio, pit slopes and equipment dimensions.