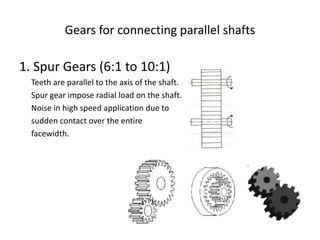

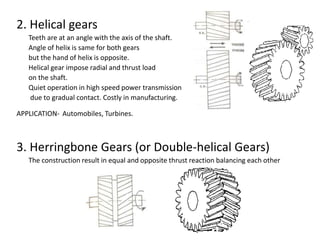

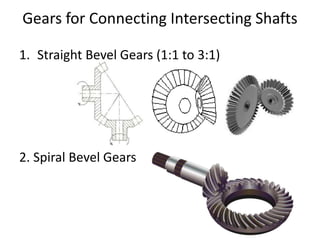

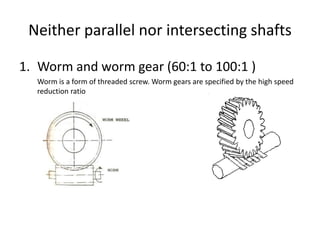

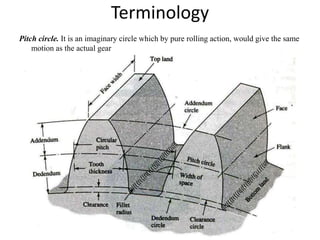

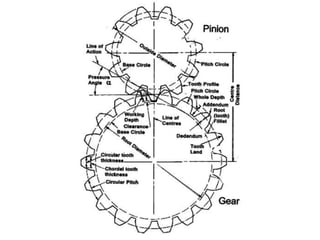

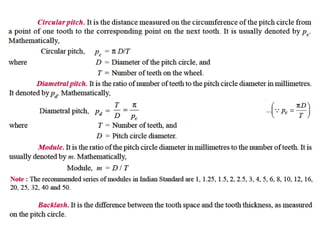

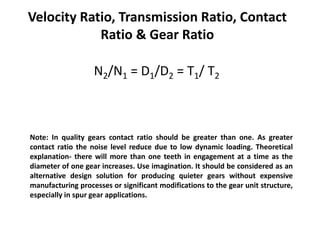

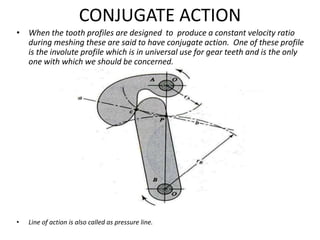

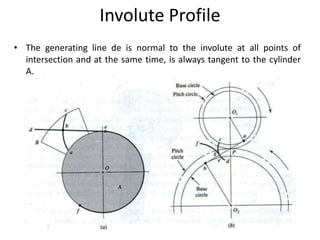

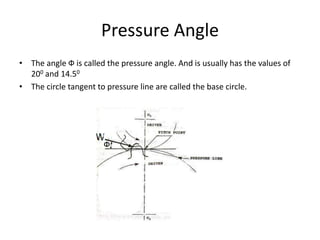

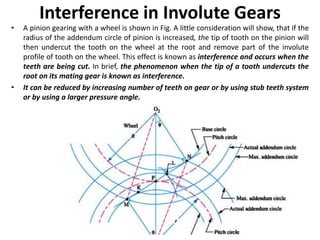

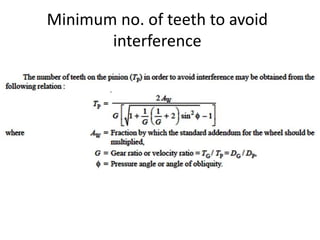

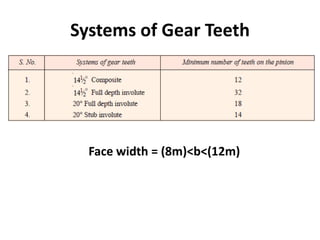

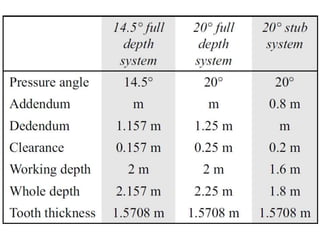

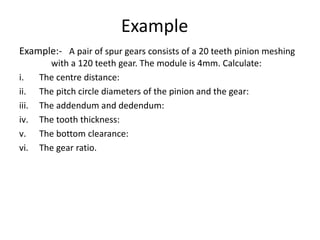

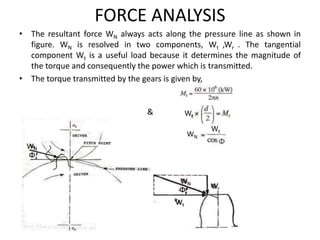

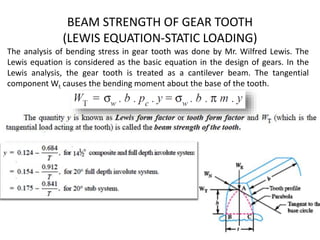

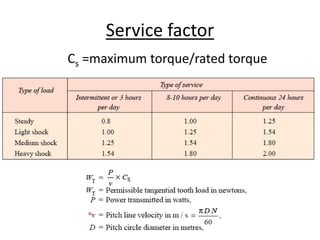

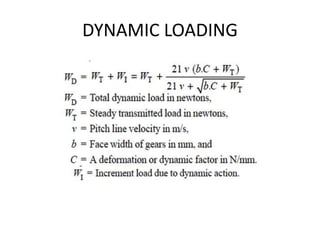

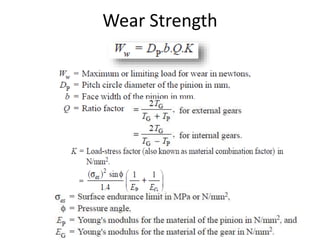

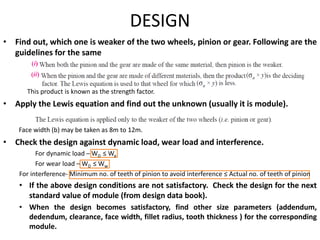

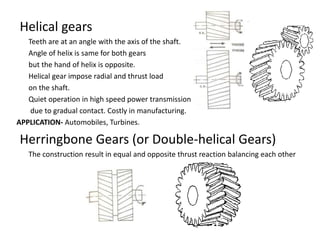

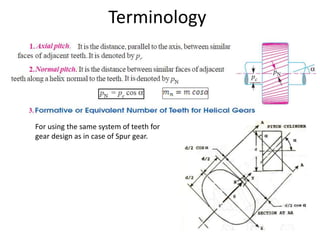

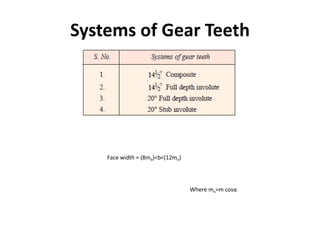

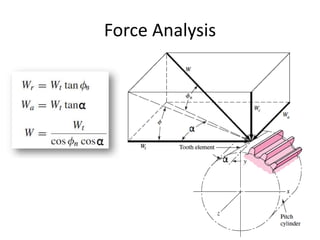

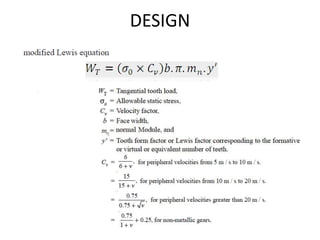

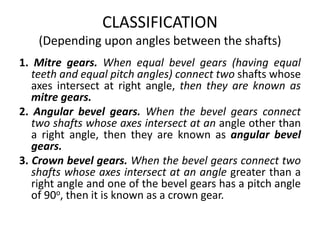

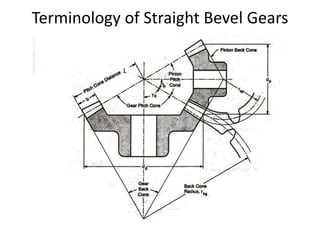

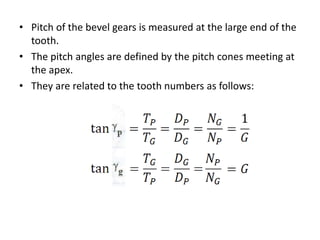

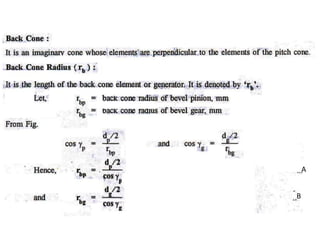

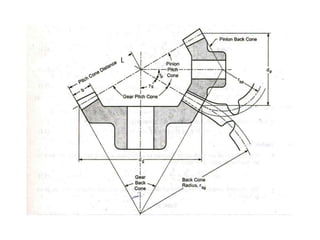

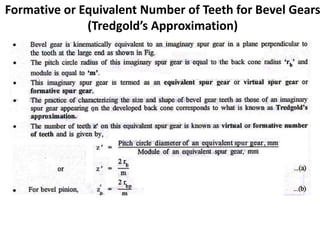

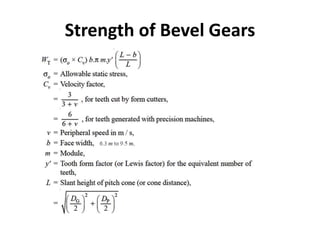

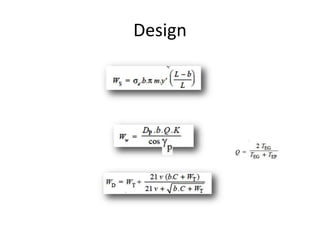

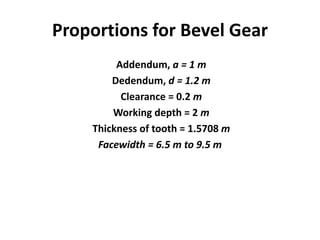

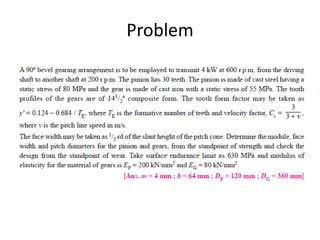

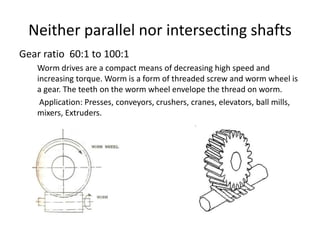

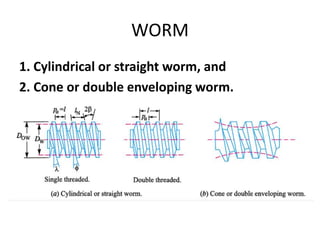

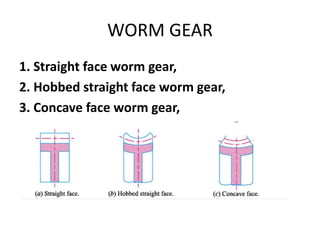

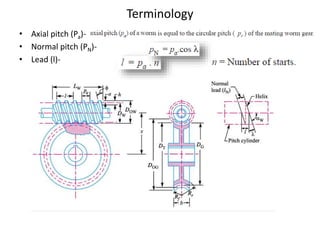

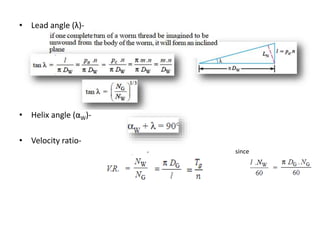

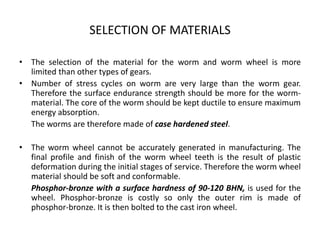

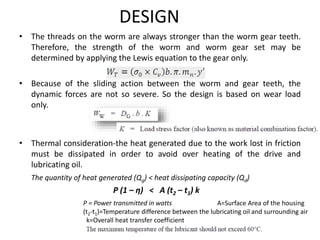

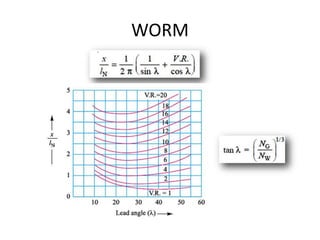

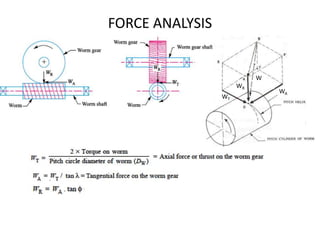

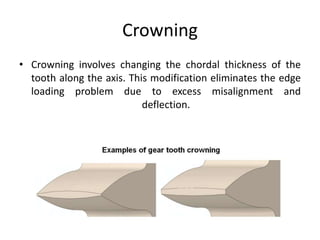

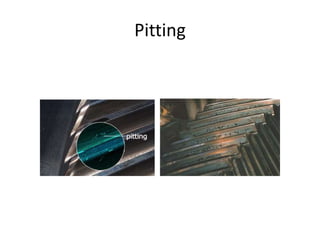

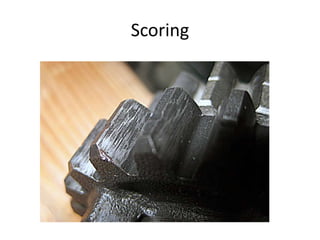

The document provides an extensive overview of gears, highlighting their definitions, advantages, classifications, and applications. It discusses various types of gears, including spur, helical, bevel, and worm gears, along with their design considerations and strength parameters. Additionally, it covers concepts such as conjugate action, interference, and force analysis relevant to gear design.