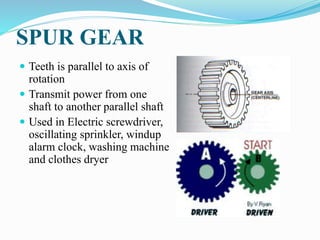

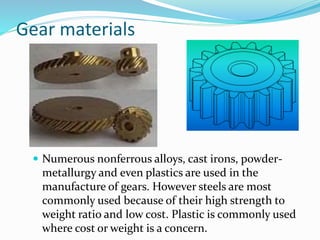

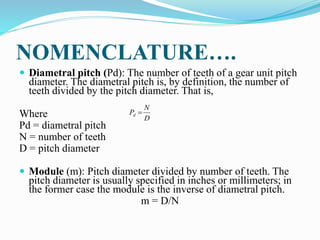

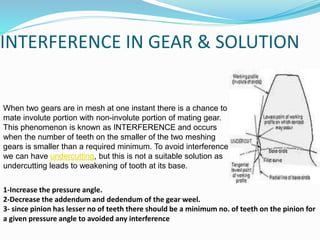

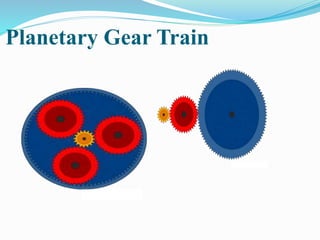

The document discusses various topics related to gear design and gear trains. It defines gears and their basic components such as teeth and axes. It describes different types of gears including spur gears, helical gears, bevel gears, worm gears, and rack and pinion gears. It also discusses gear ratios, velocity ratios, interference in gears, and different types of gear trains such as simple, compound, and planetary gear trains. The document provides illustrations and explanations of each gear type and gear train.