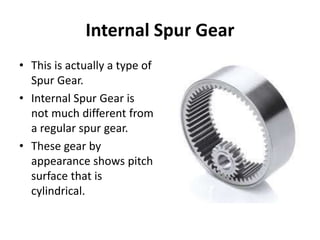

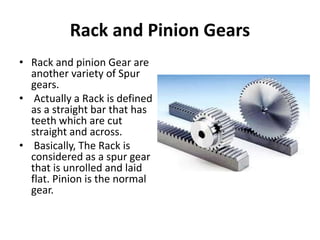

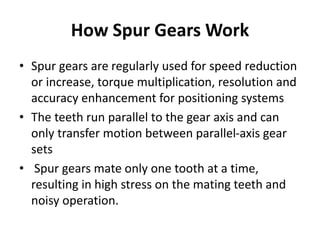

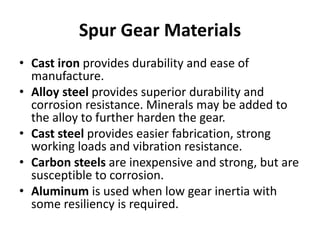

This document discusses spur gears, including their types, materials, applications, advantages, and disadvantages. It describes how spur gears are the simplest type of gear that transmit power between parallel axes with teeth projecting radially. The main types are external, internal, and rack and pinion gears. Common materials include cast iron, alloy steels, cast steel, carbon steels, and aluminum. Spur gears are widely used in machines, engines, clocks, and other applications. Their advantages are high efficiency, compact size, and reliability, while disadvantages include cost, limited center distance, noise, and stress on teeth.