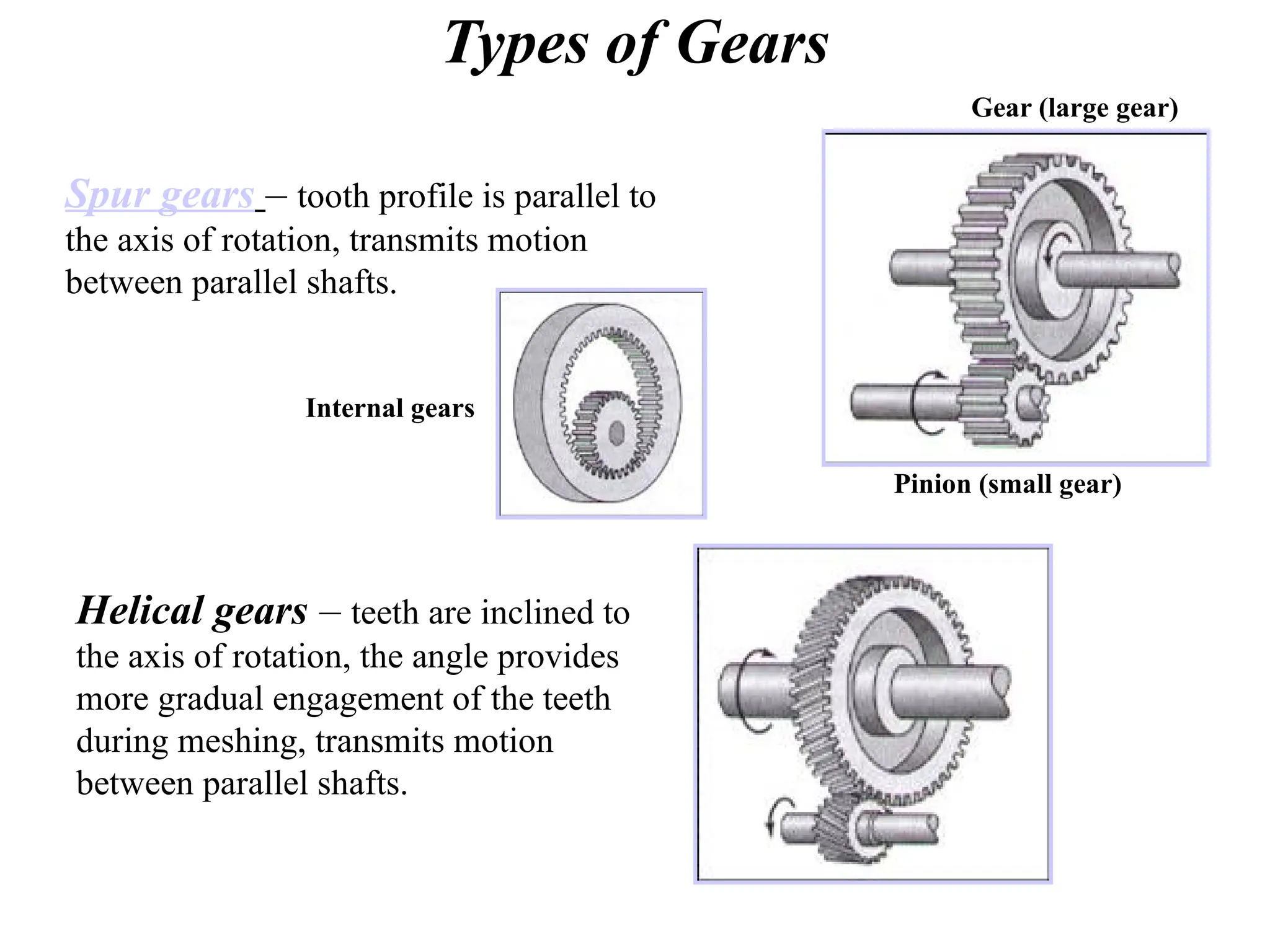

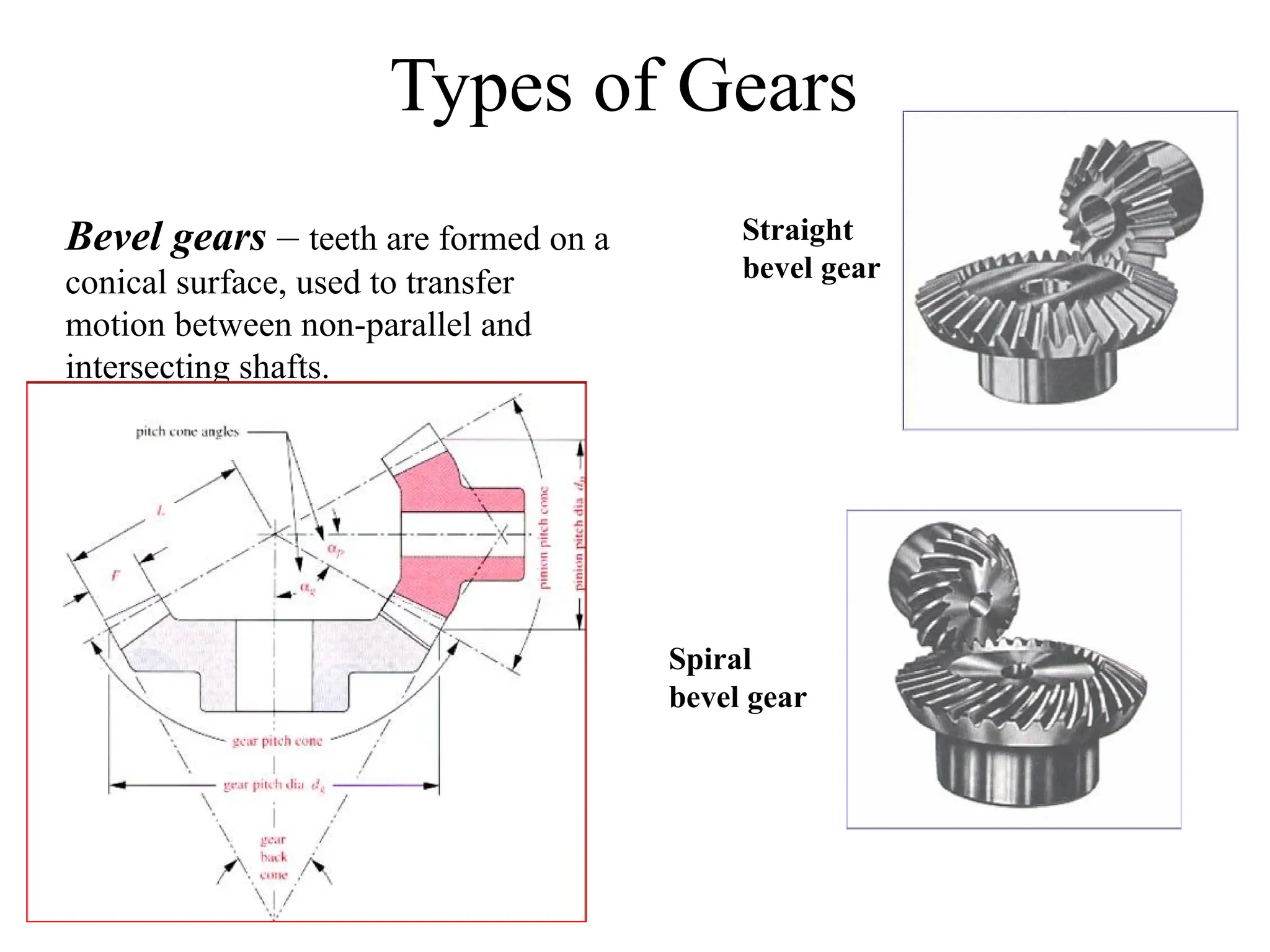

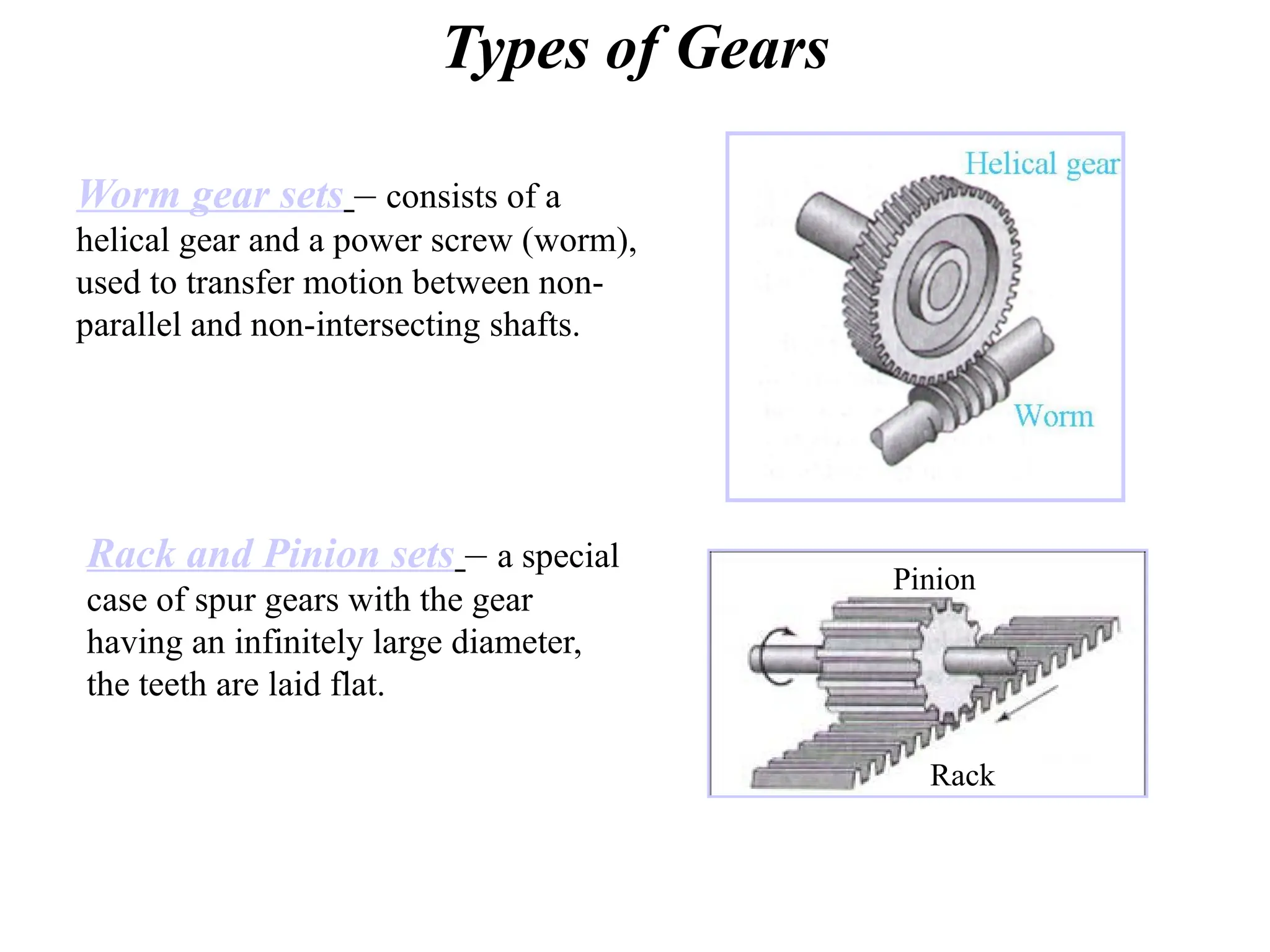

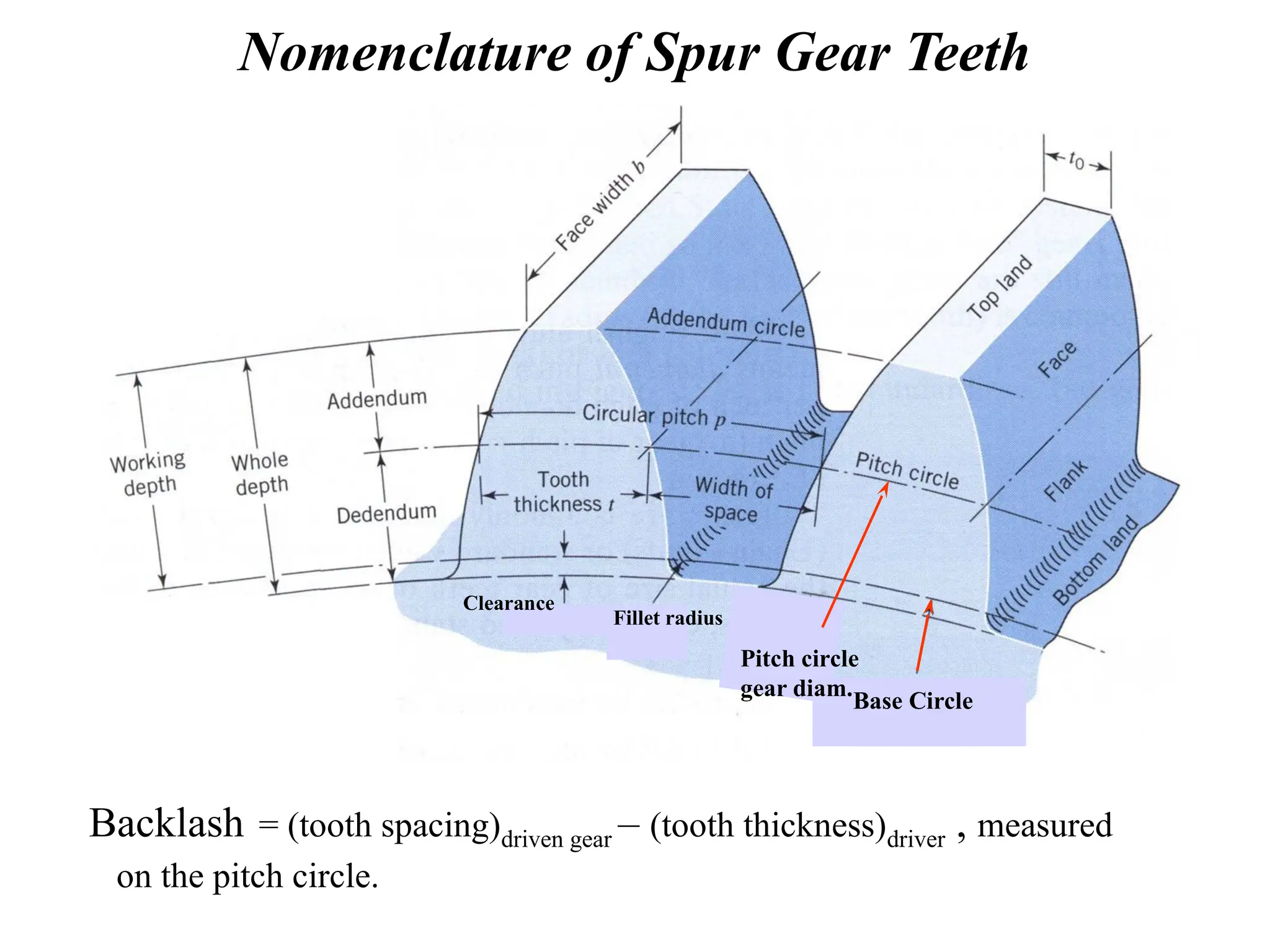

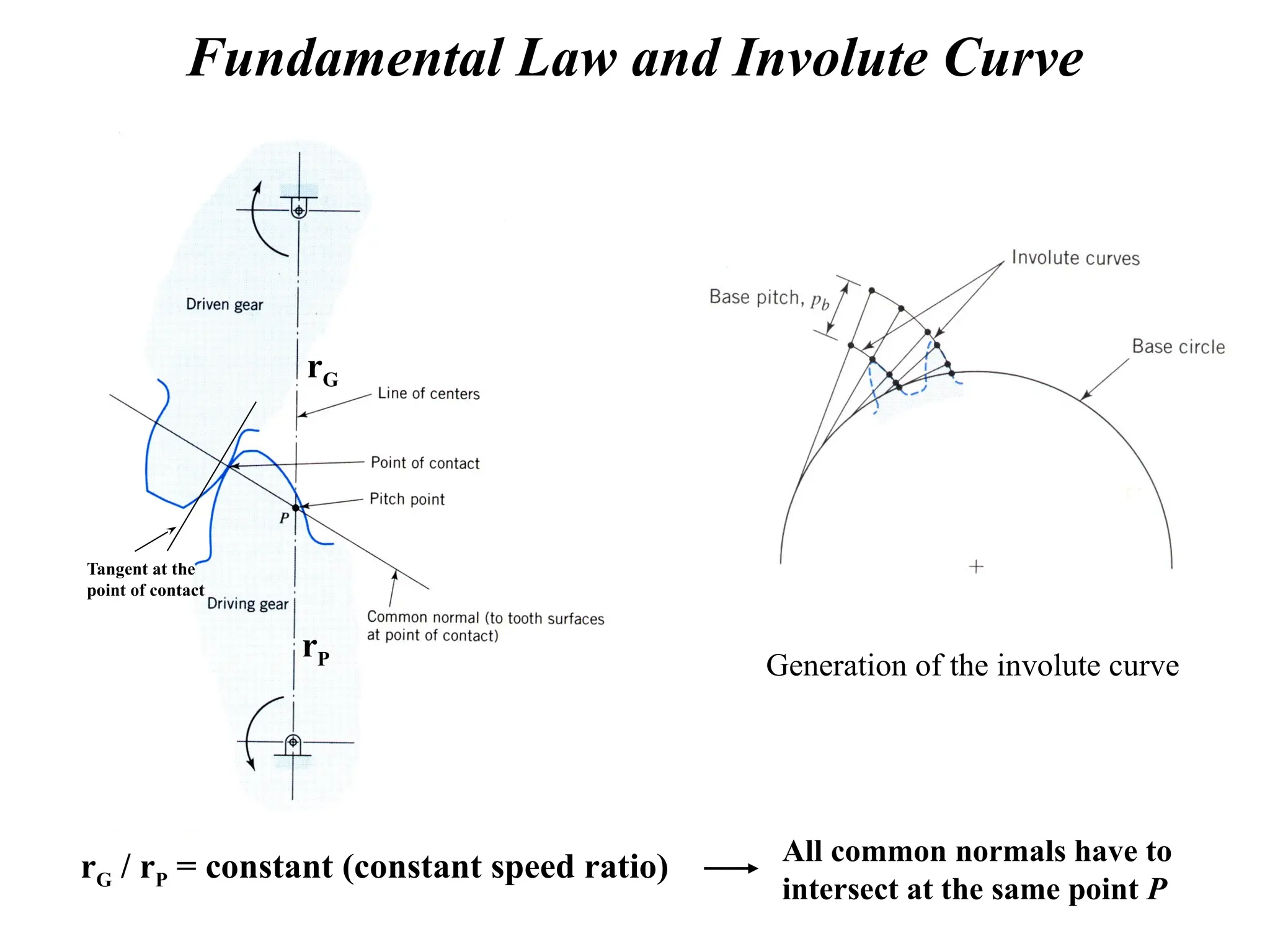

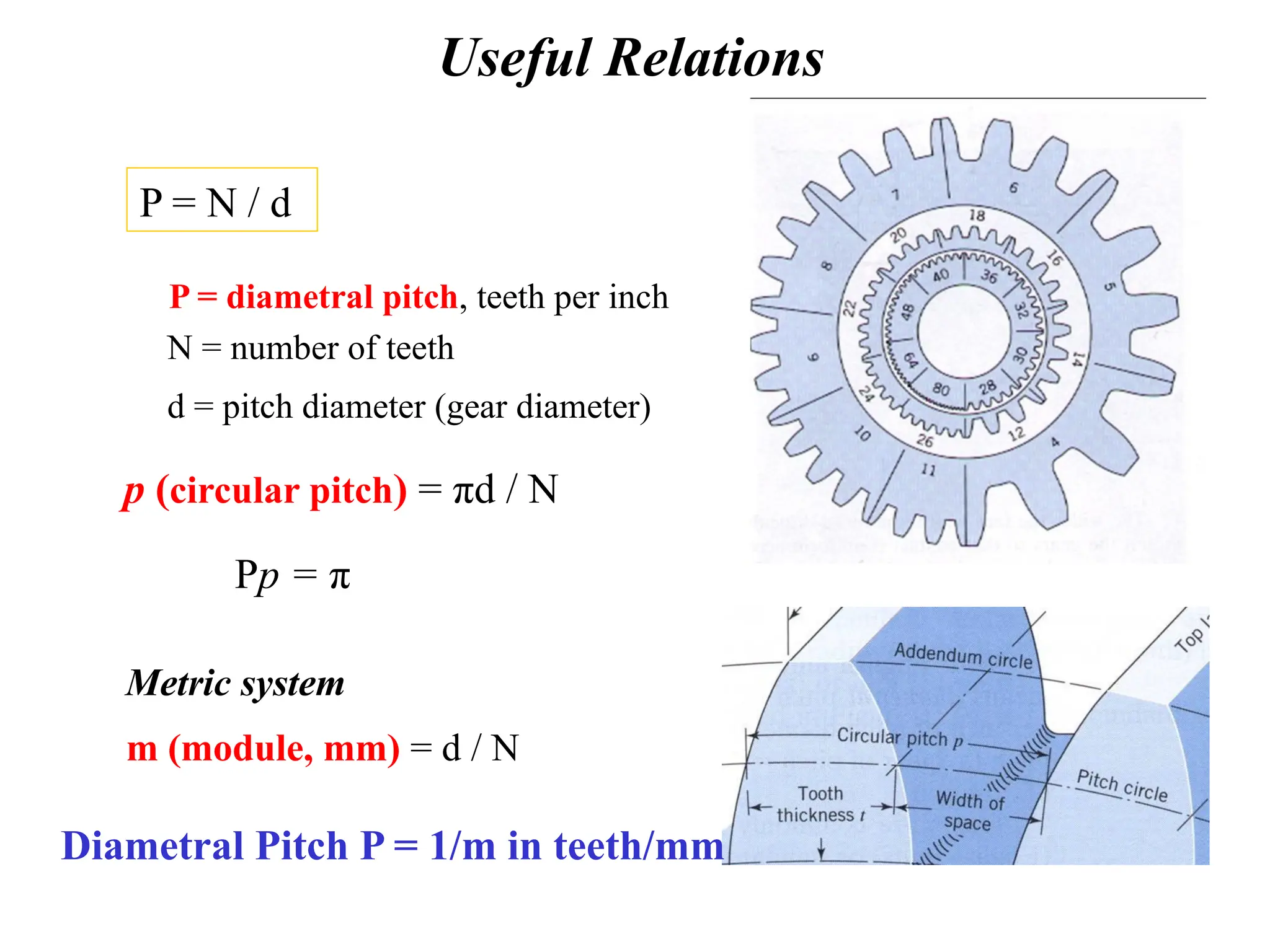

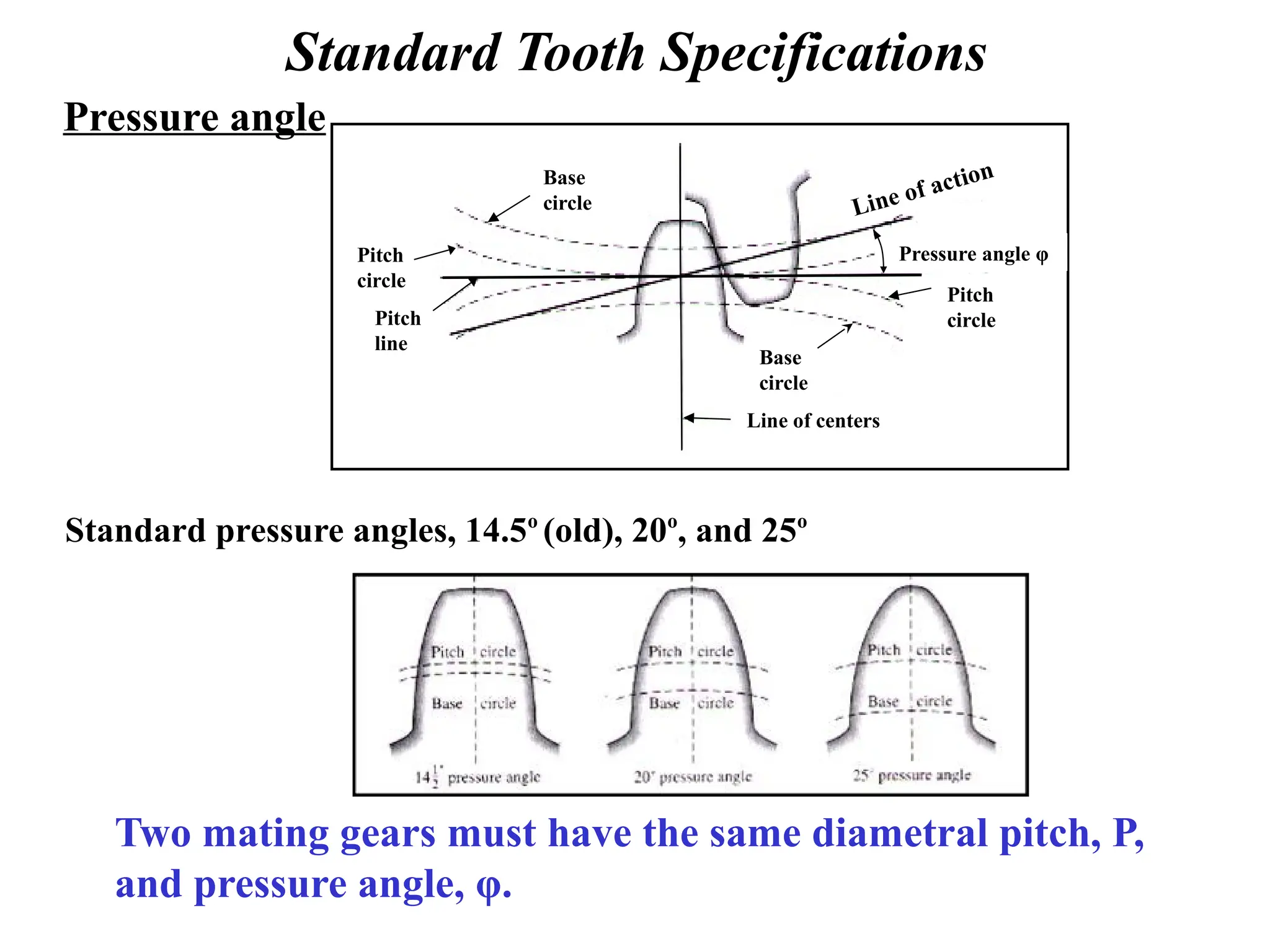

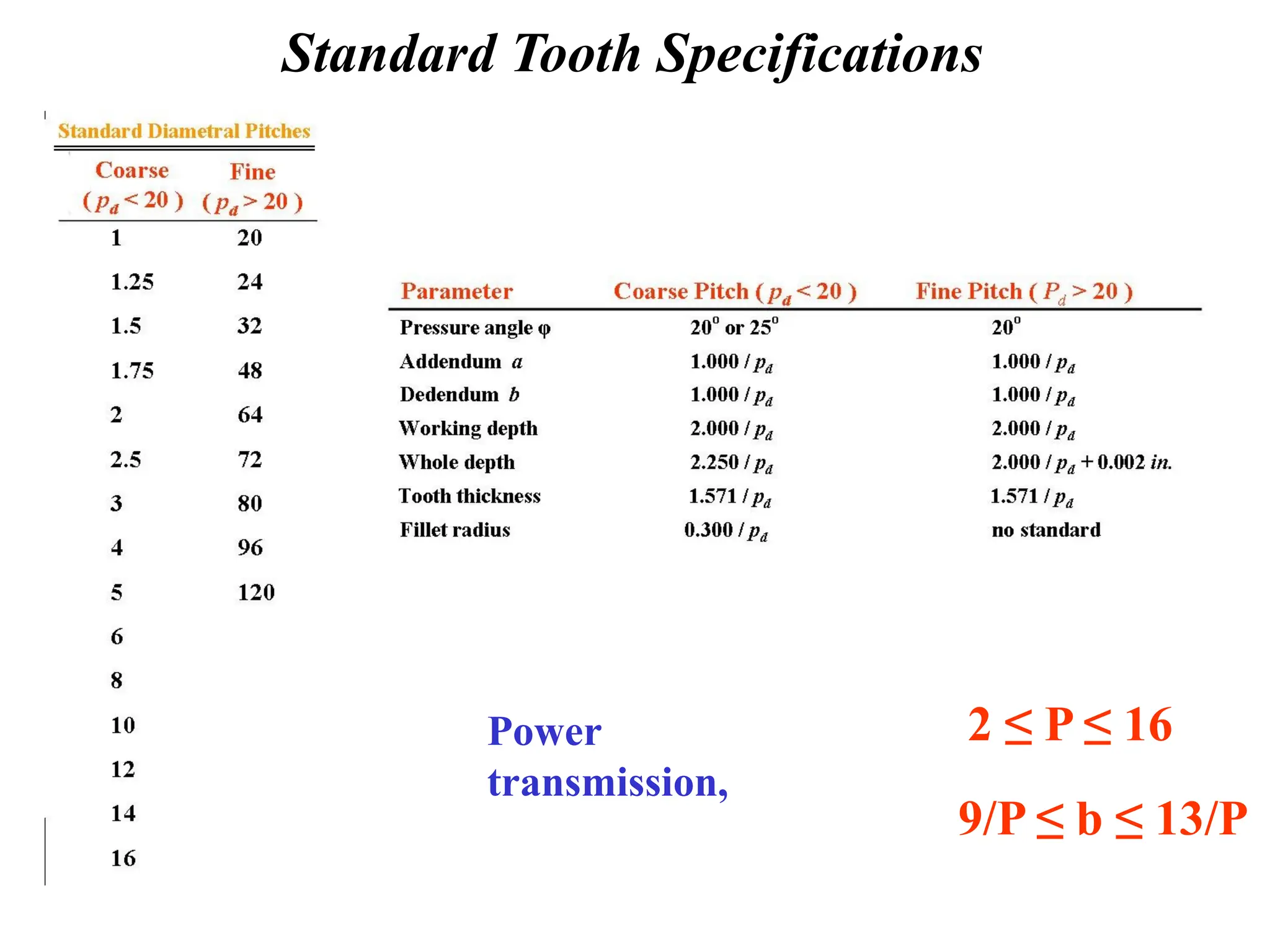

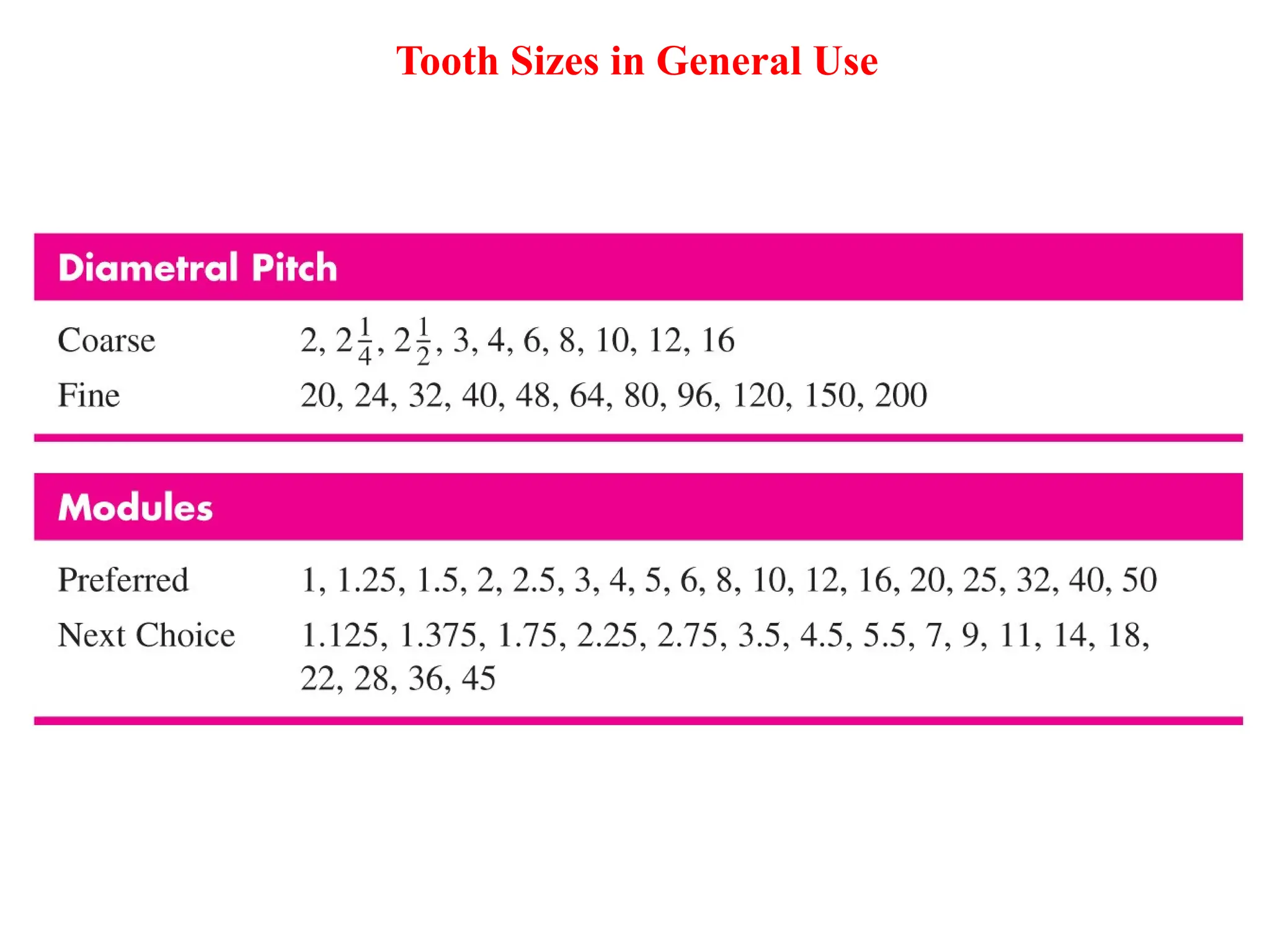

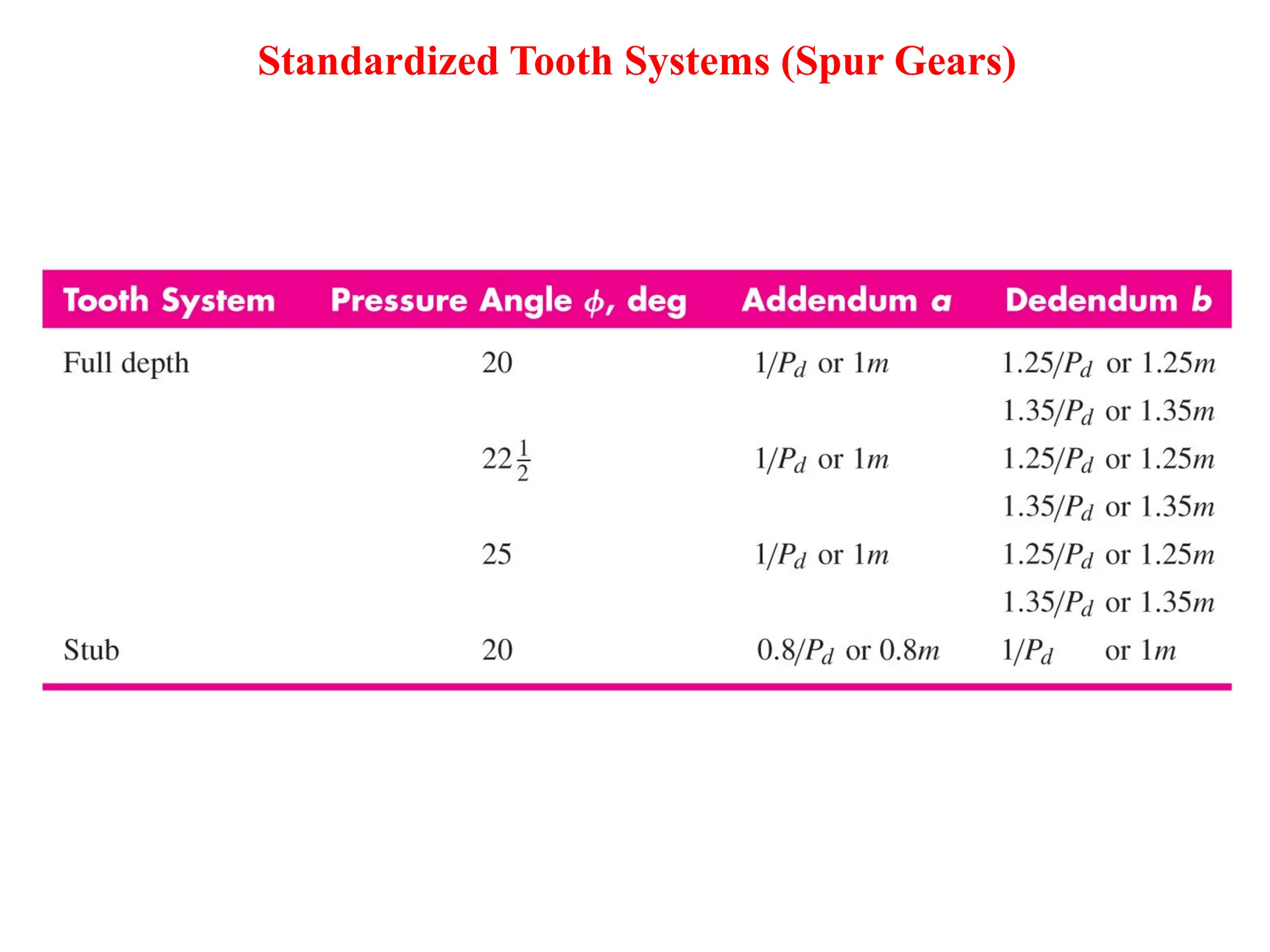

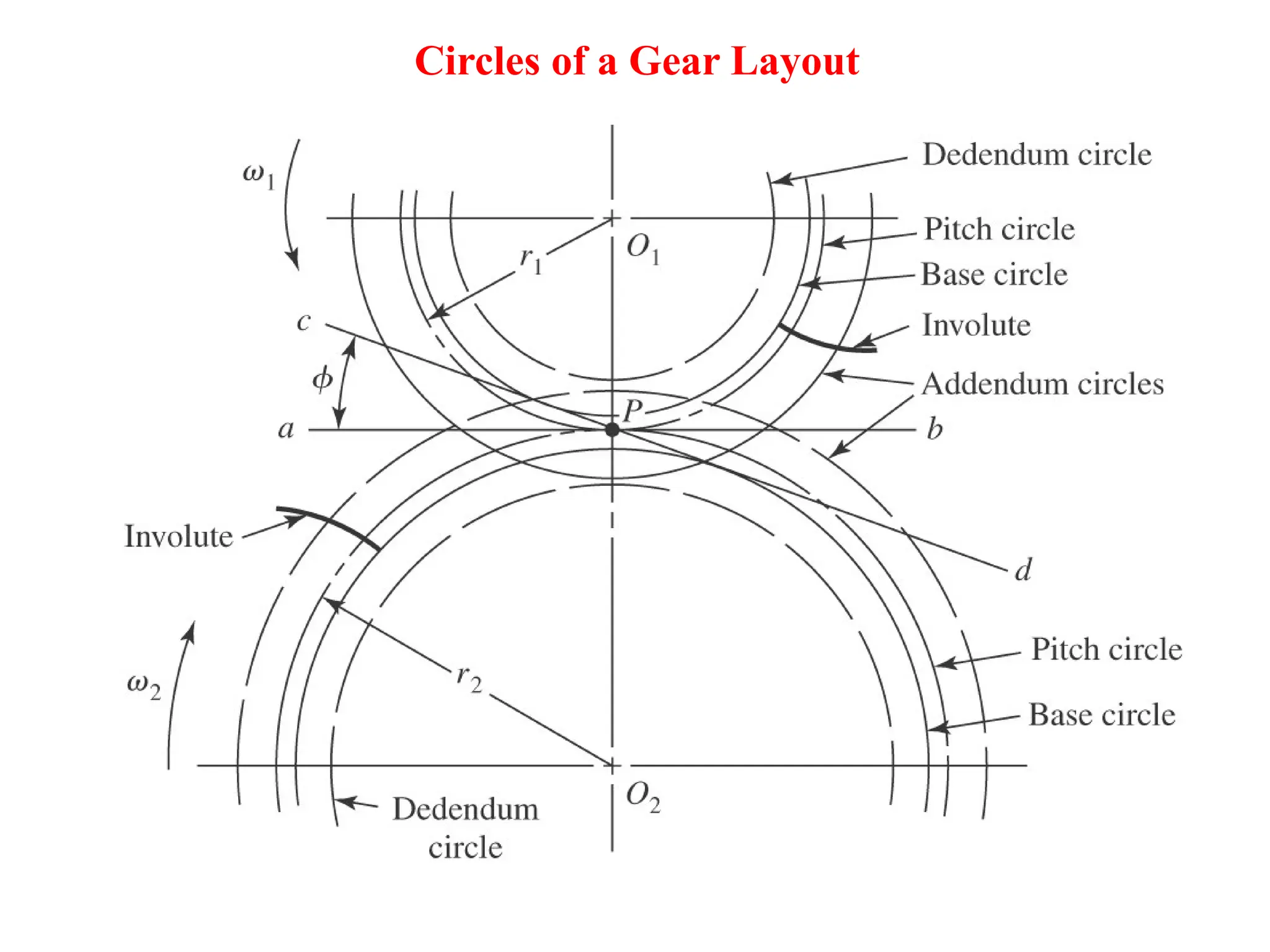

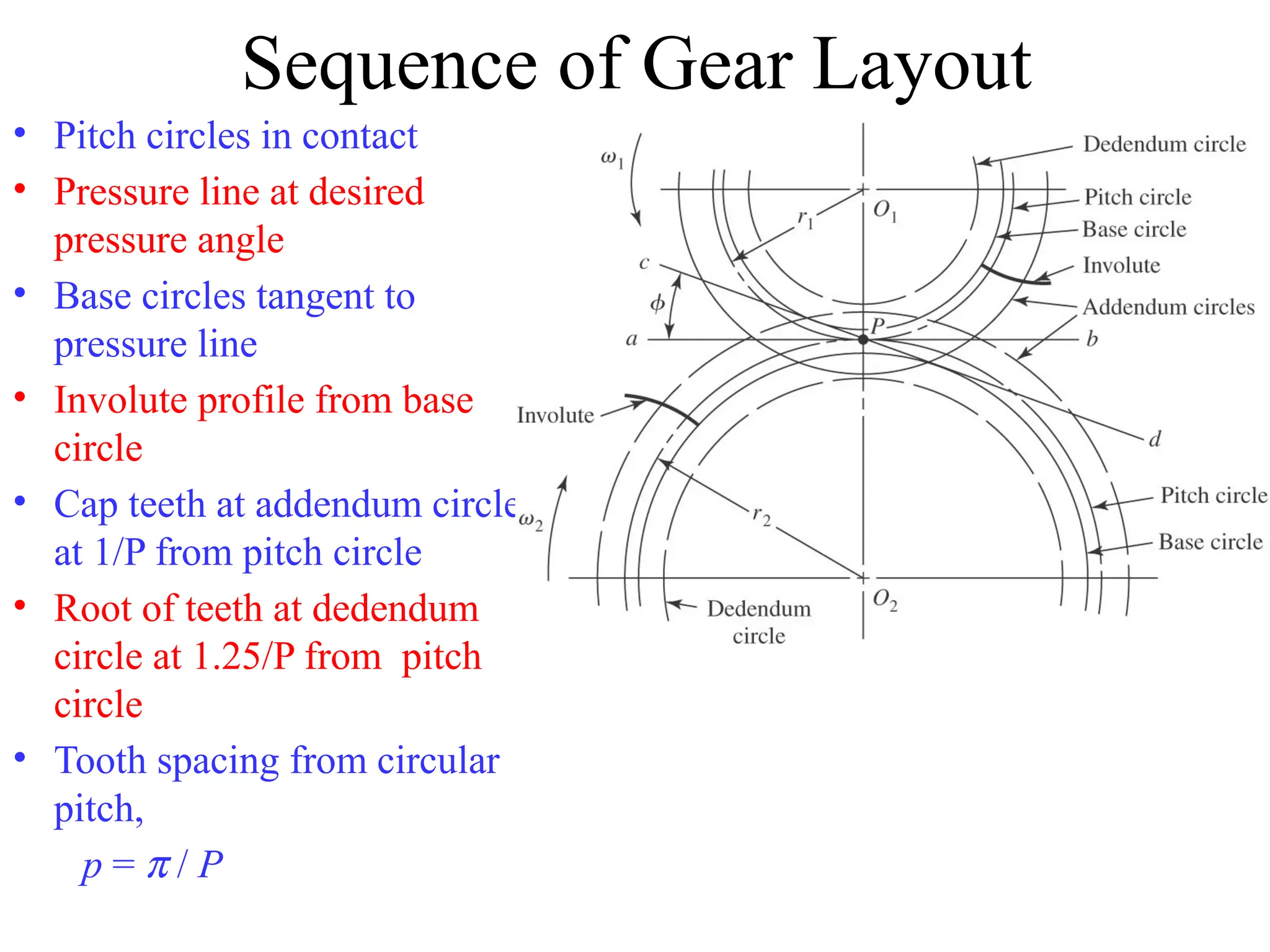

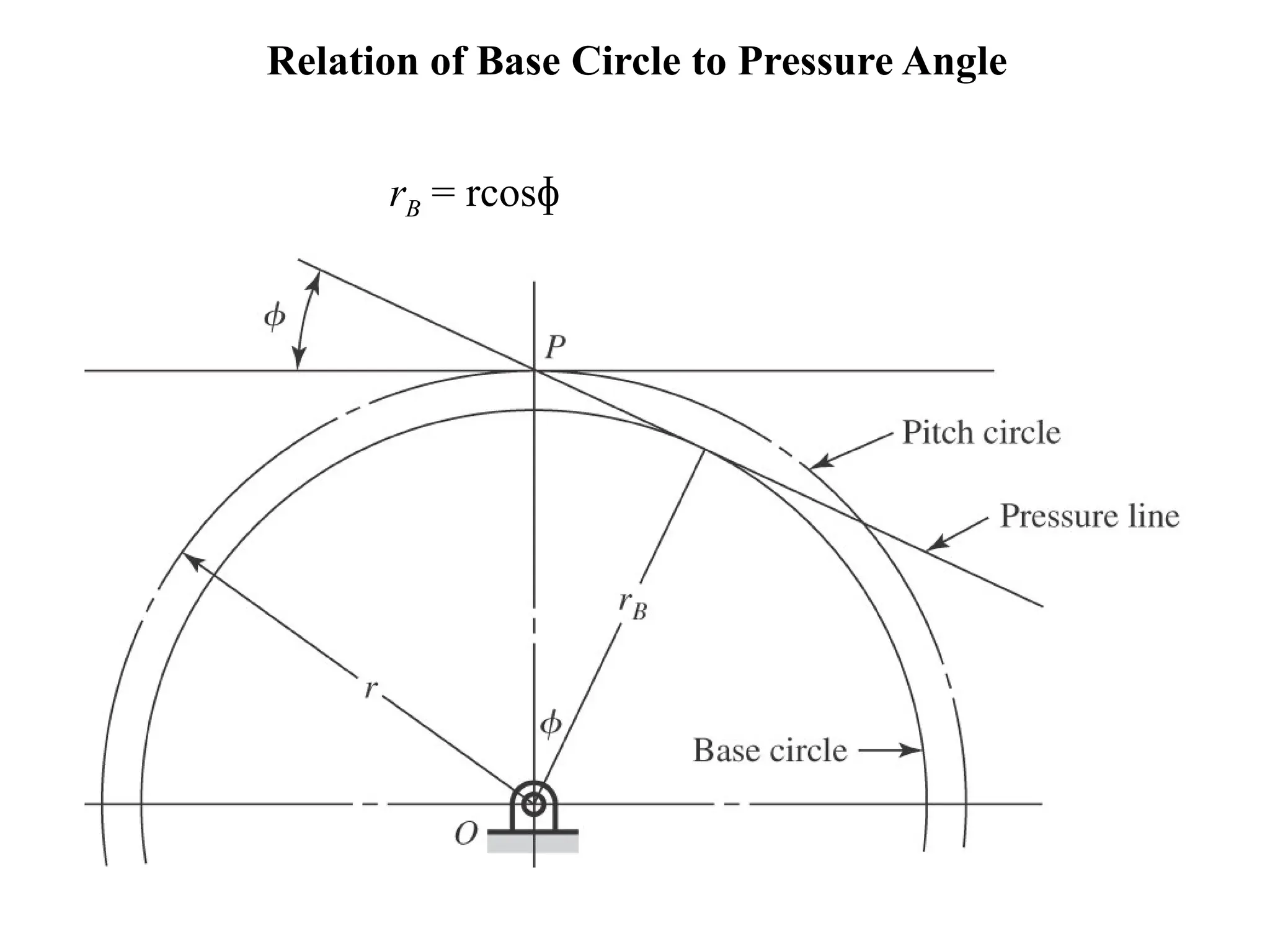

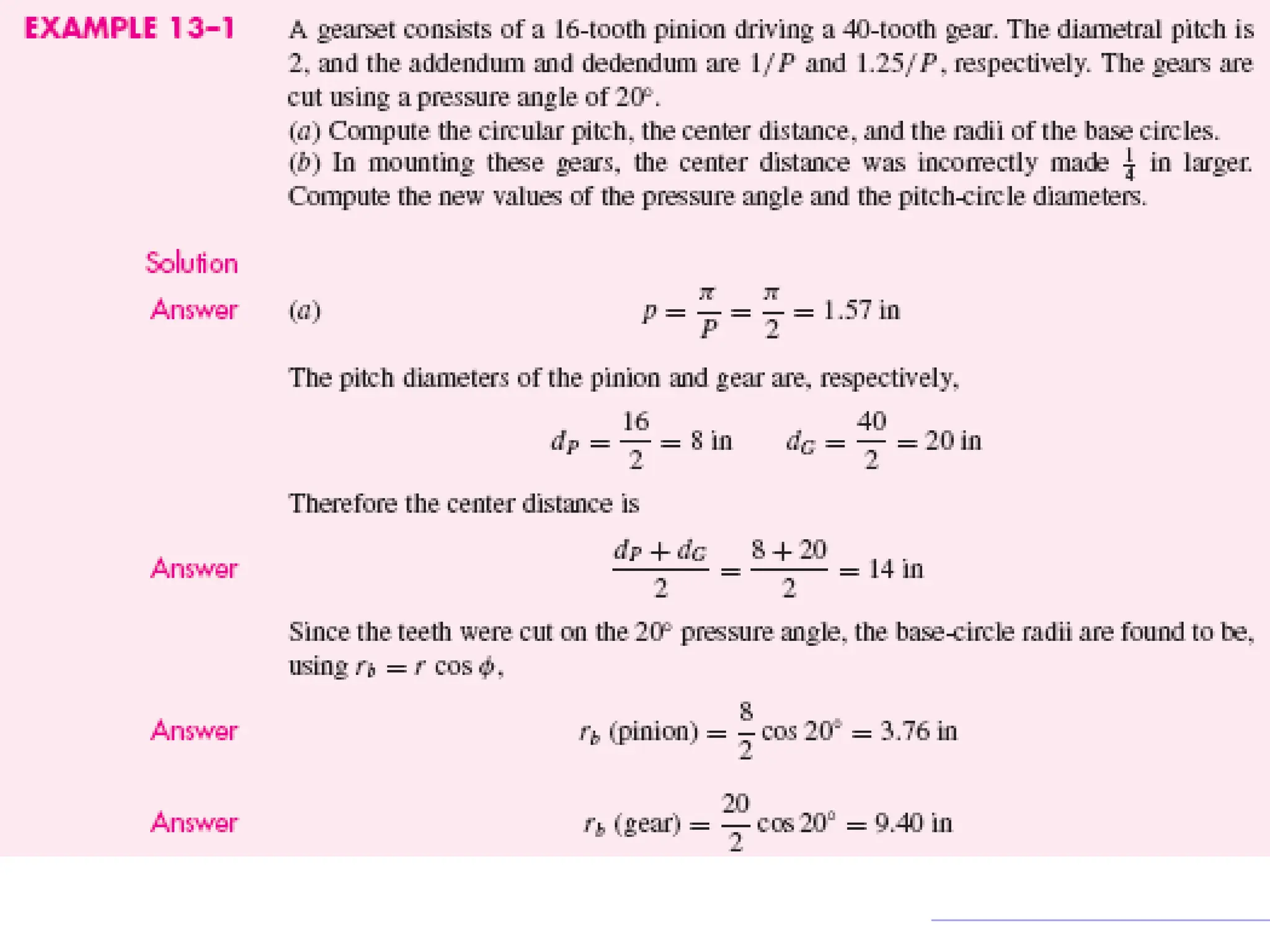

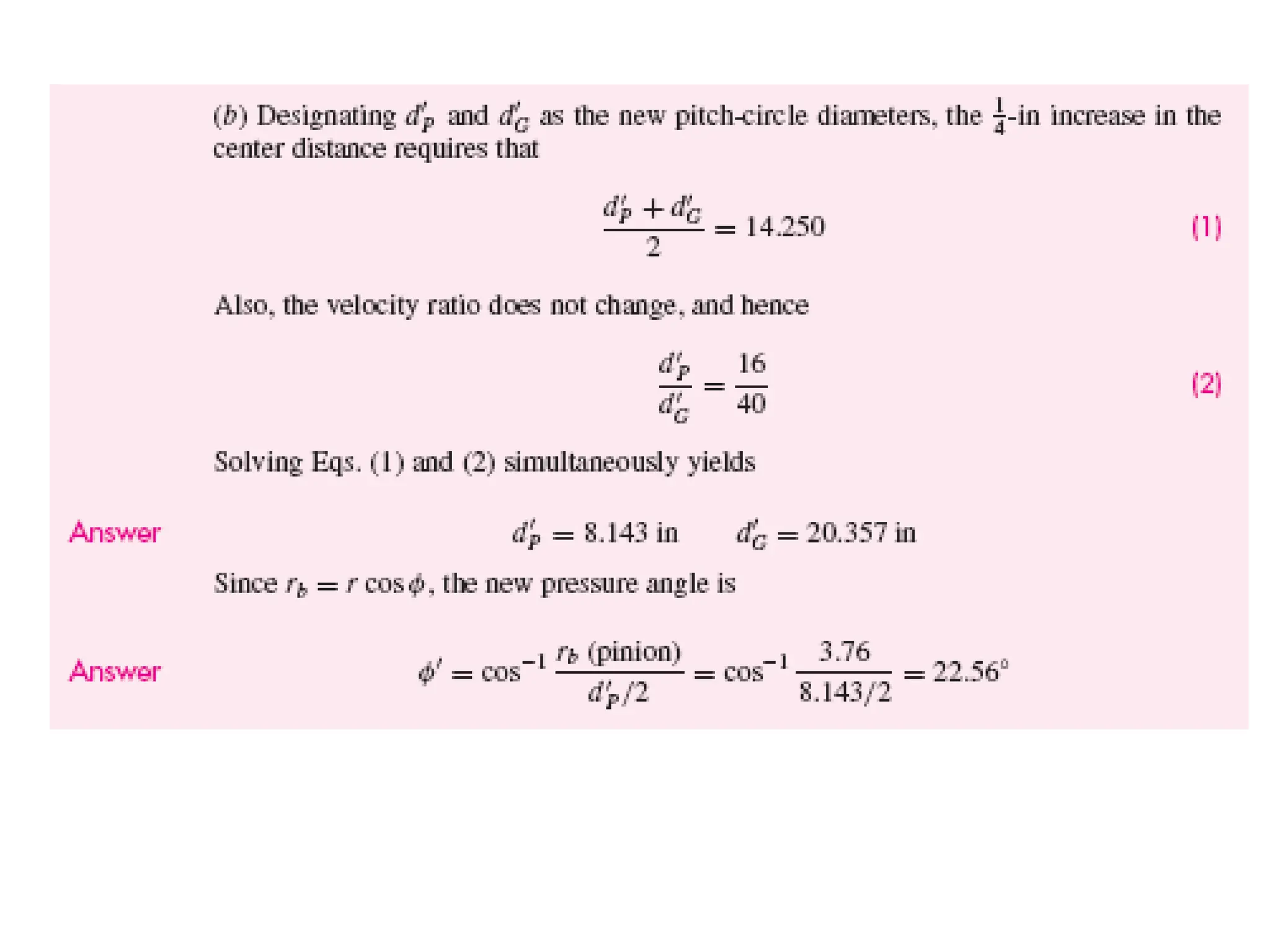

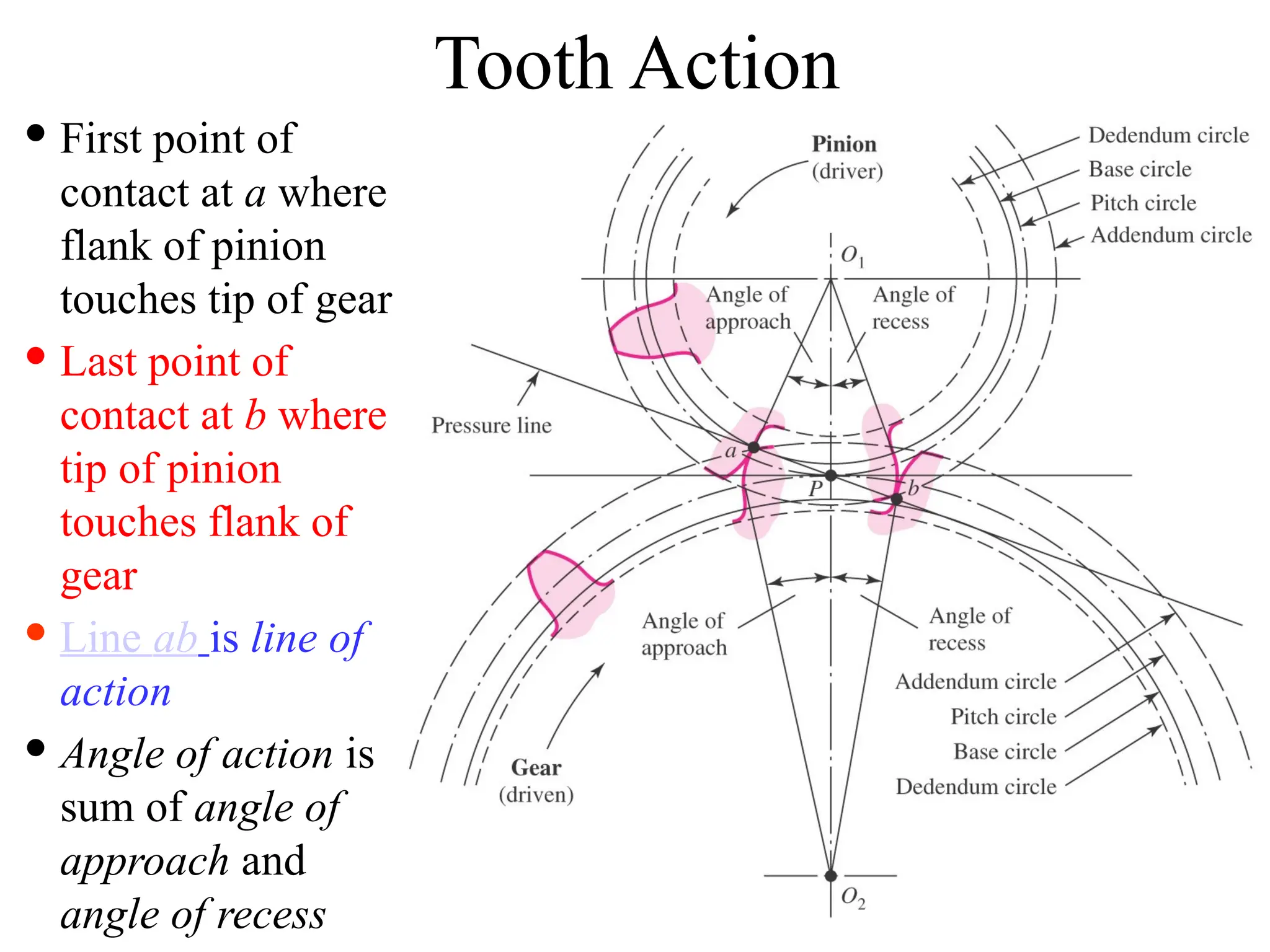

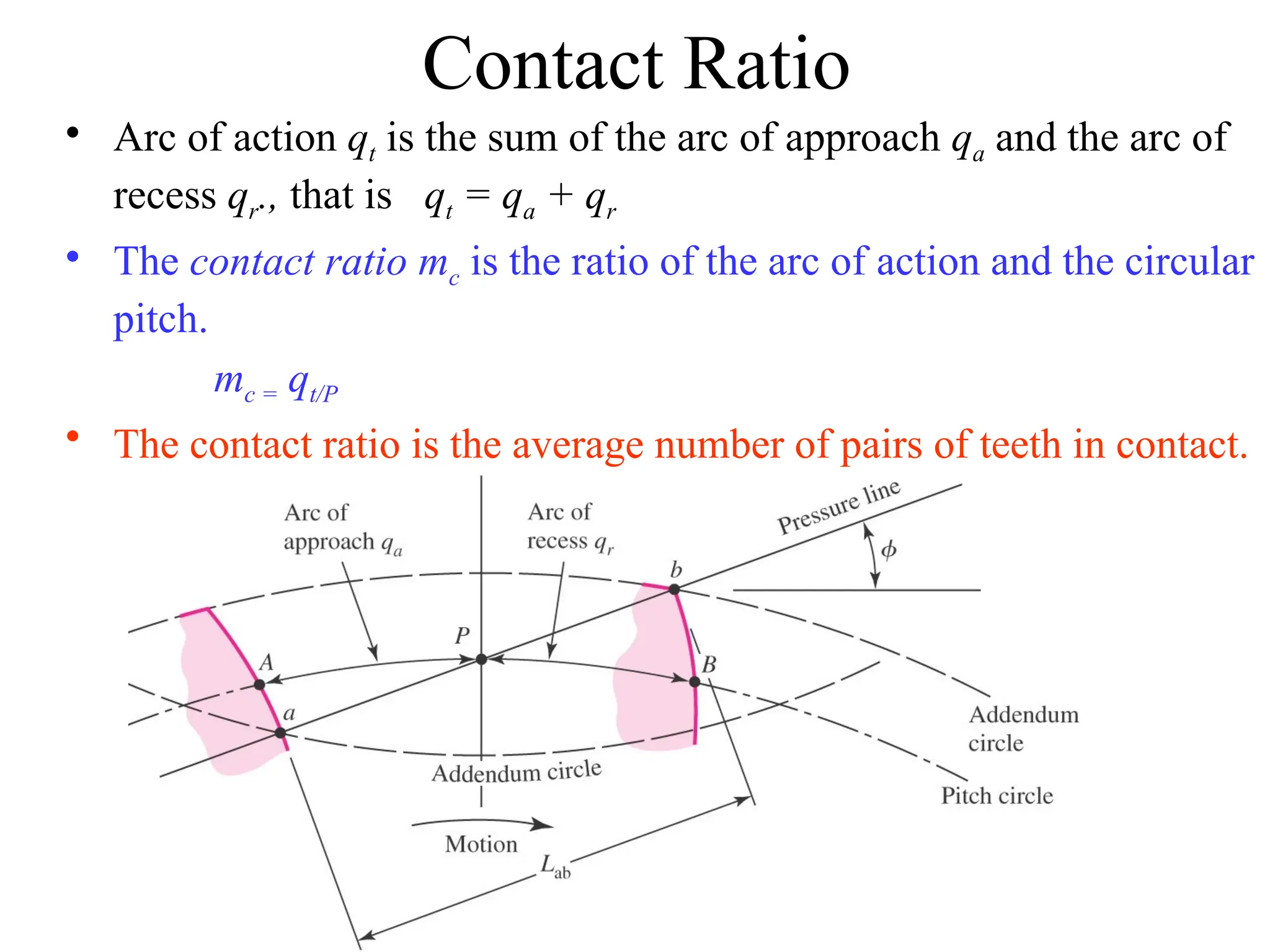

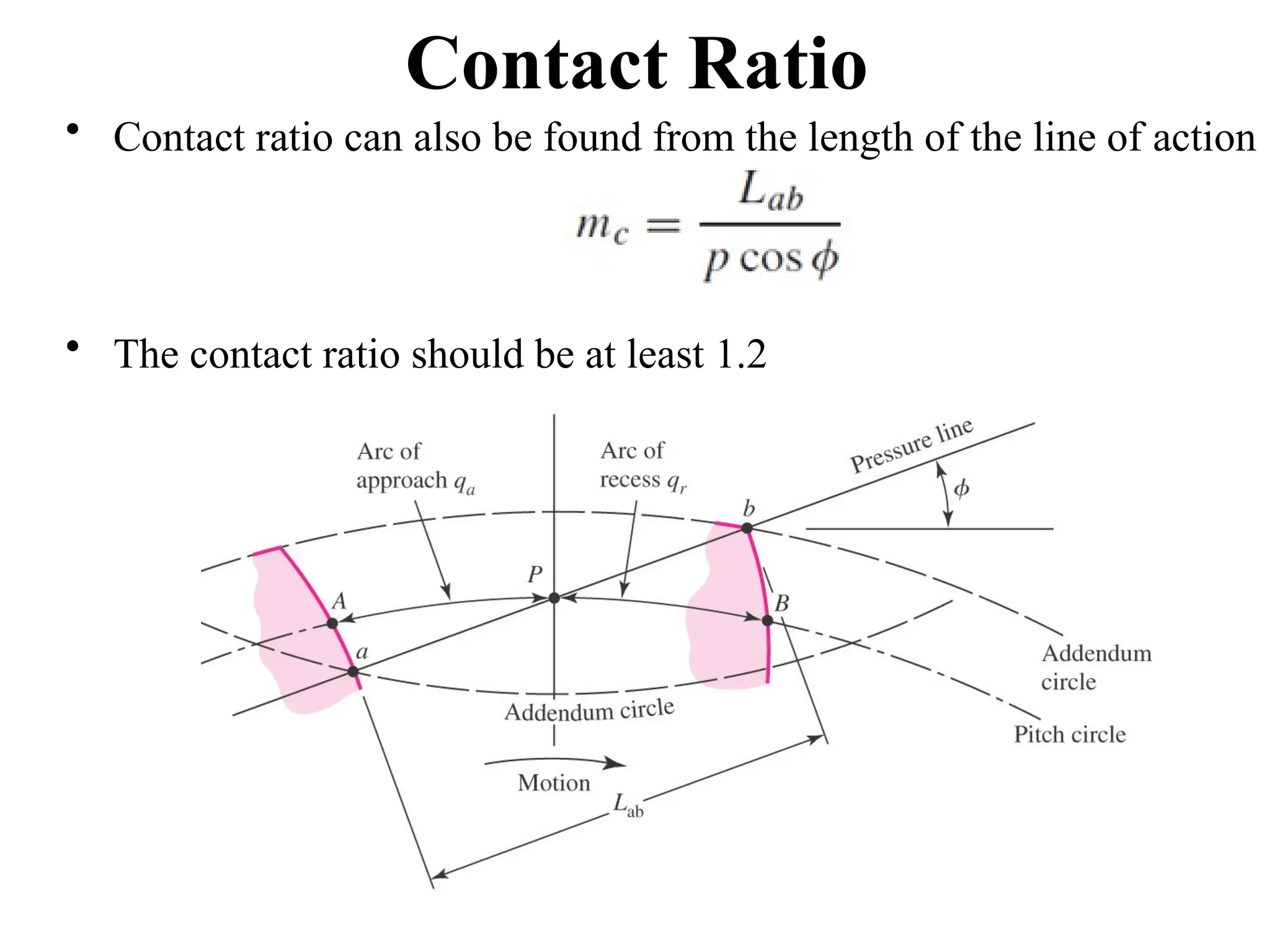

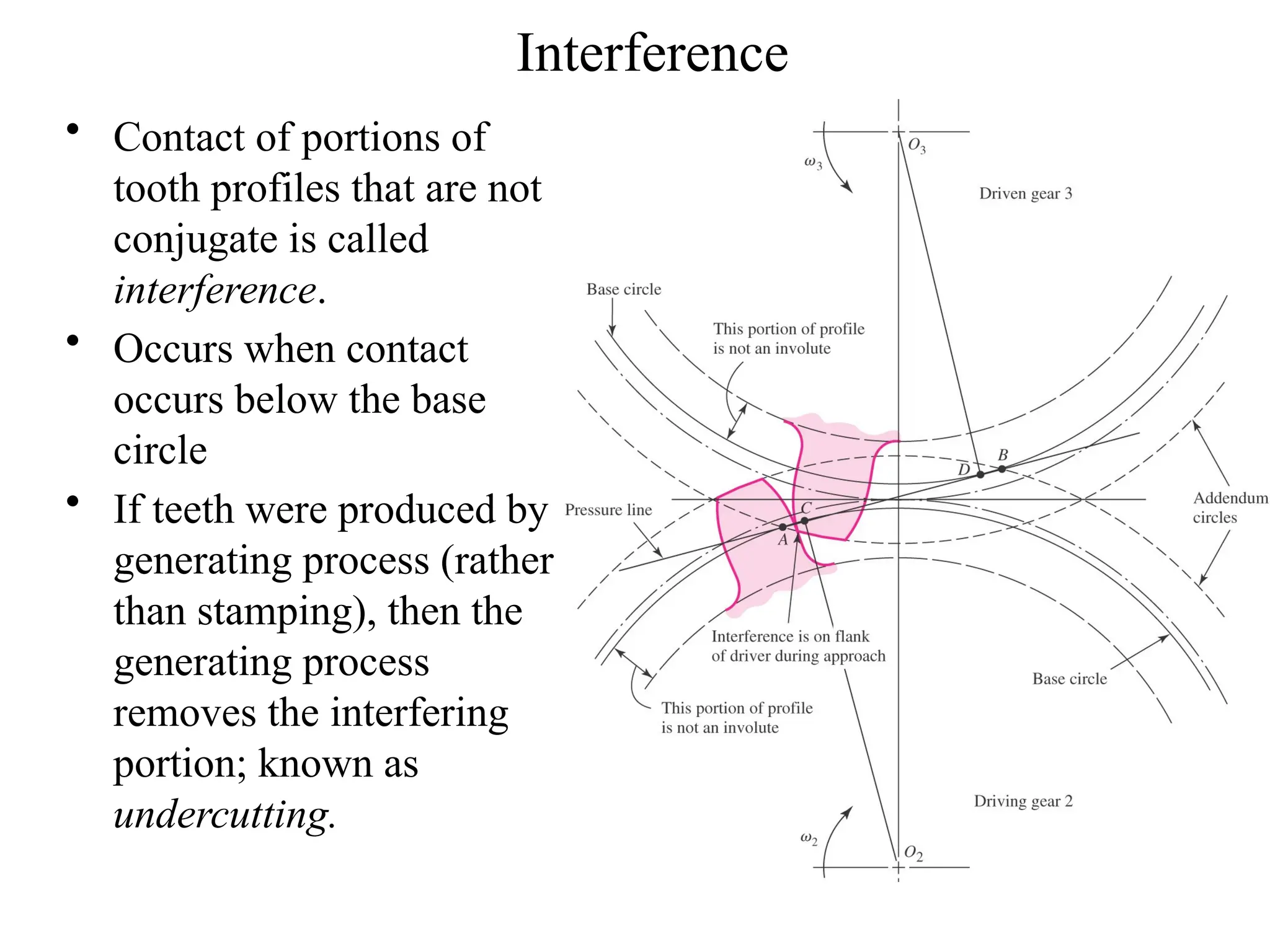

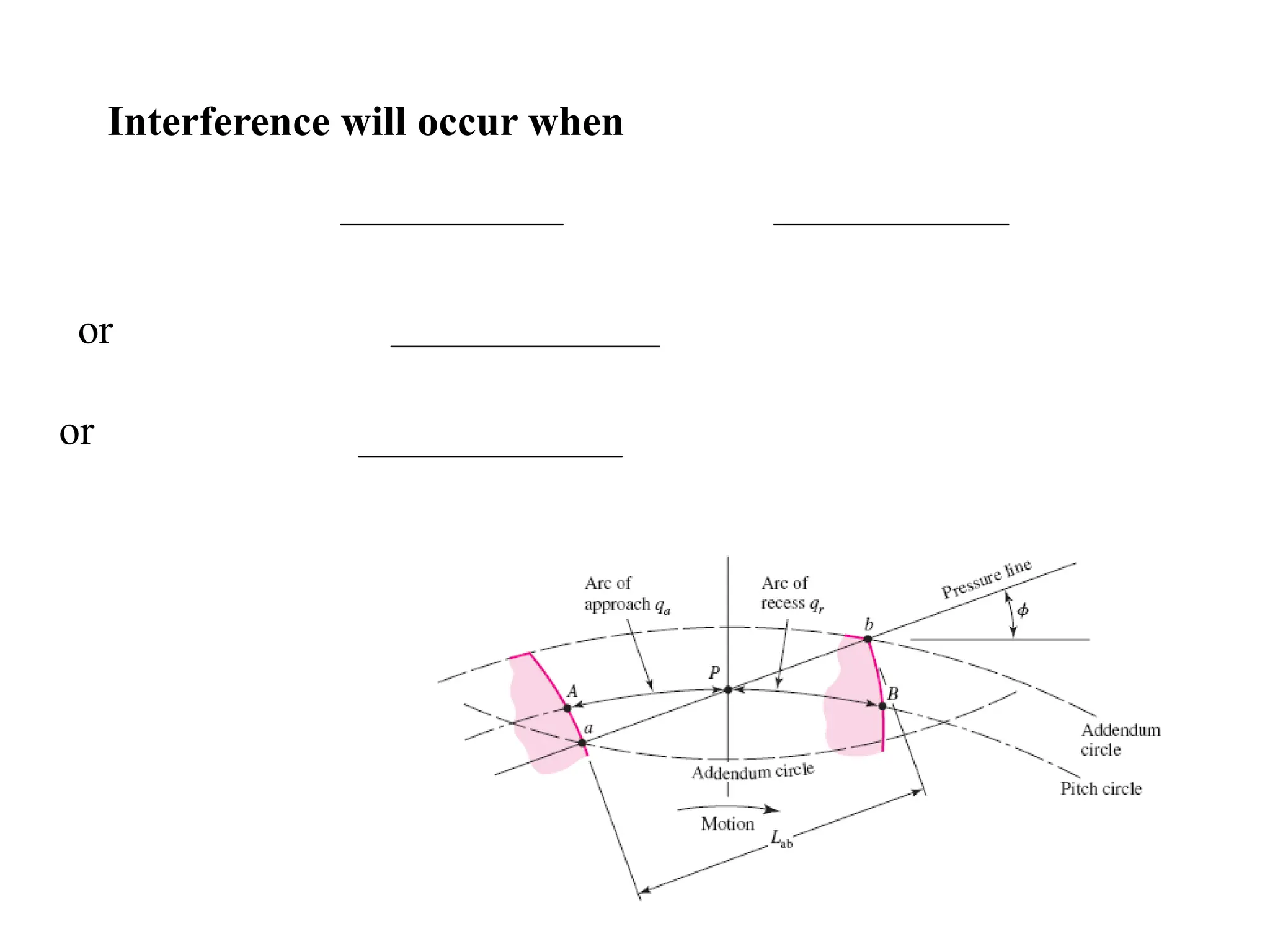

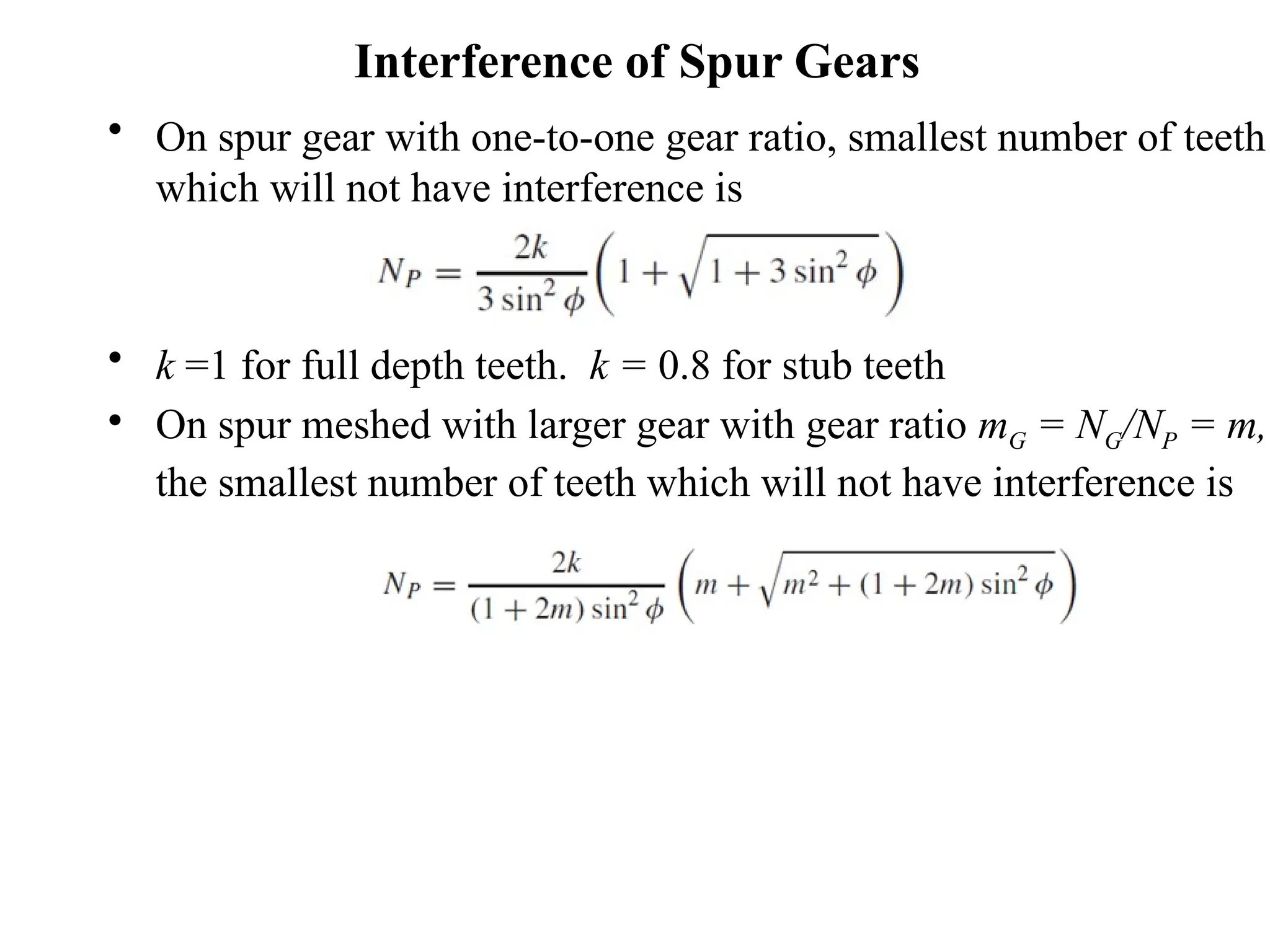

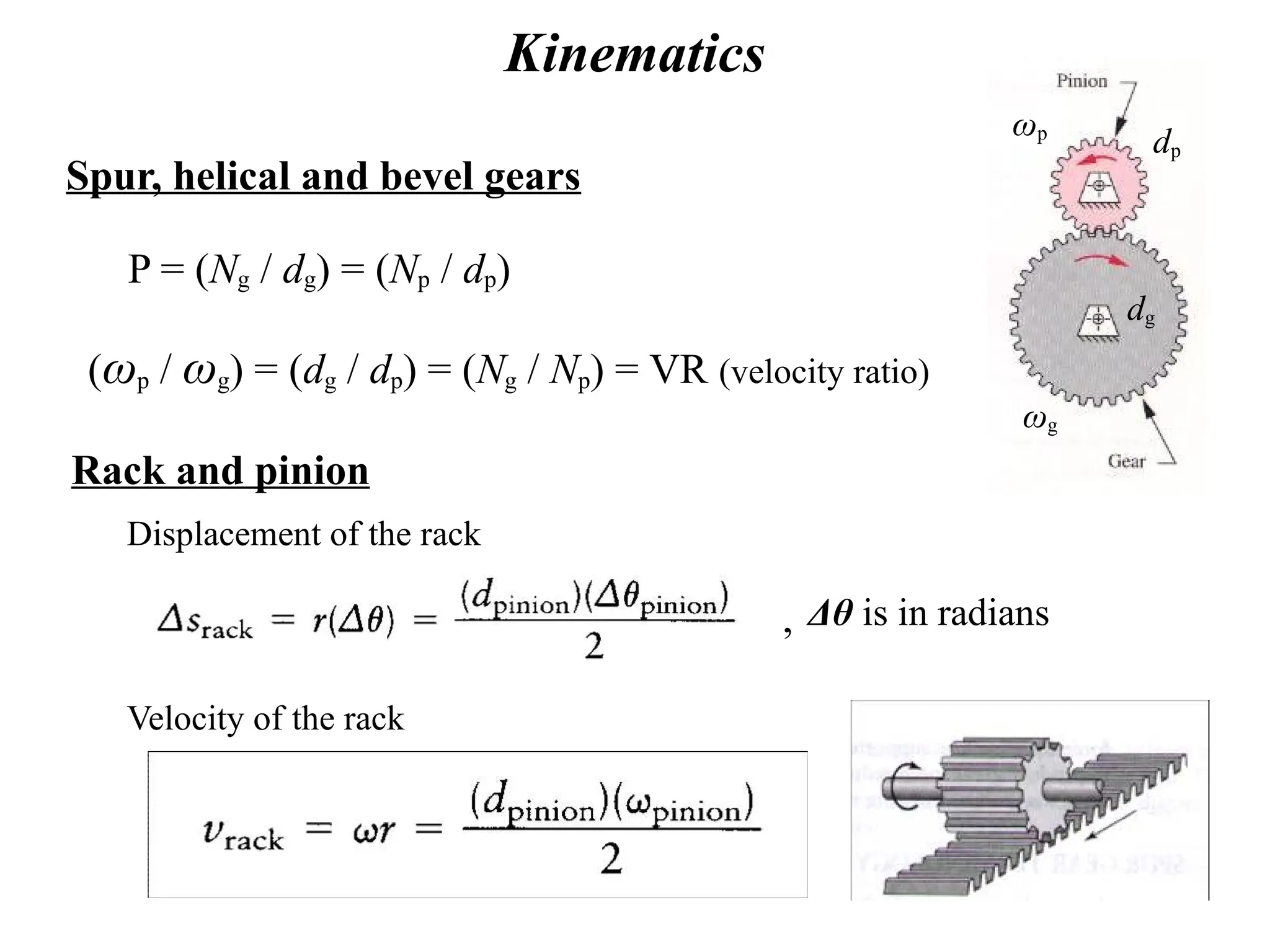

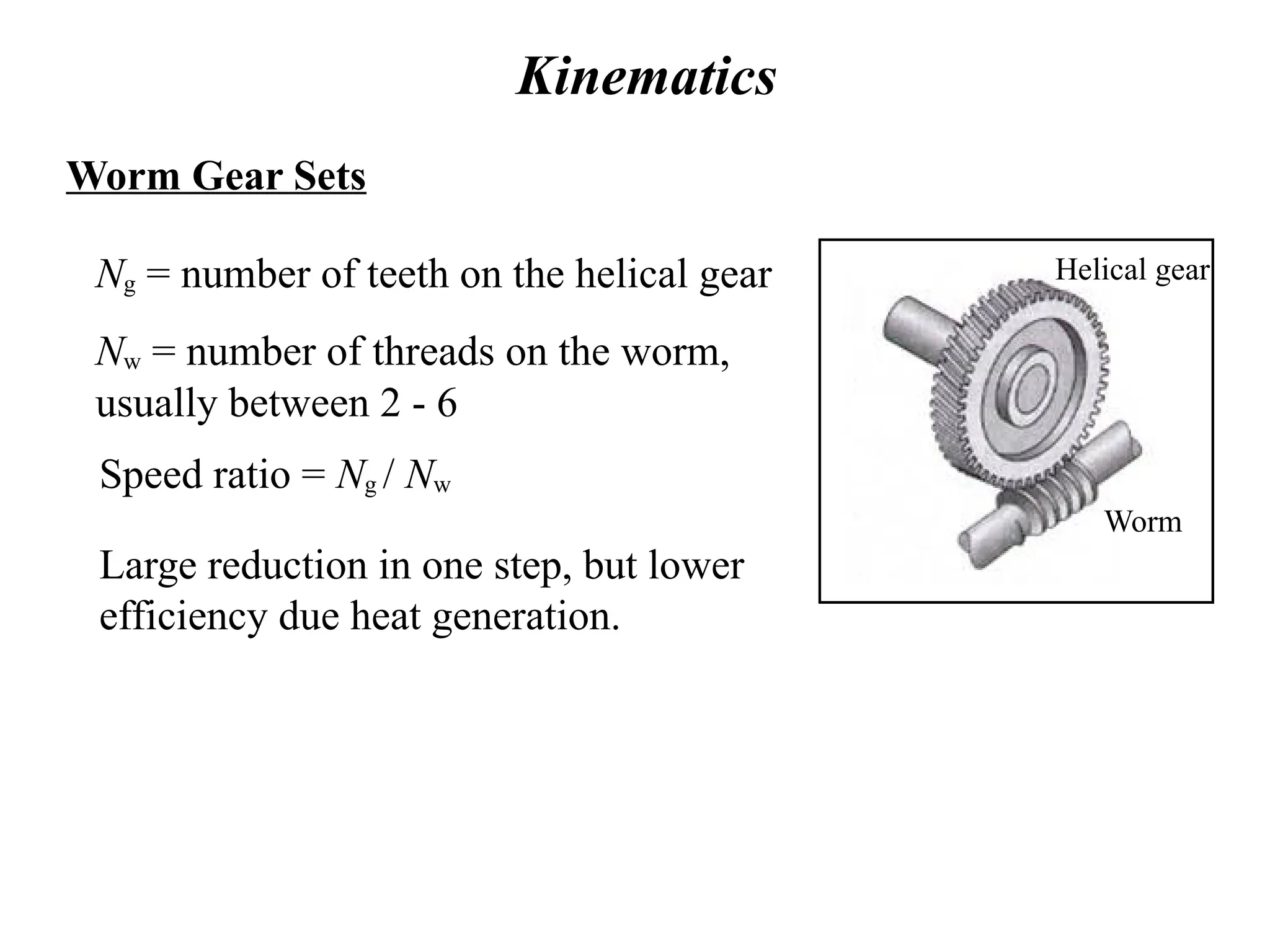

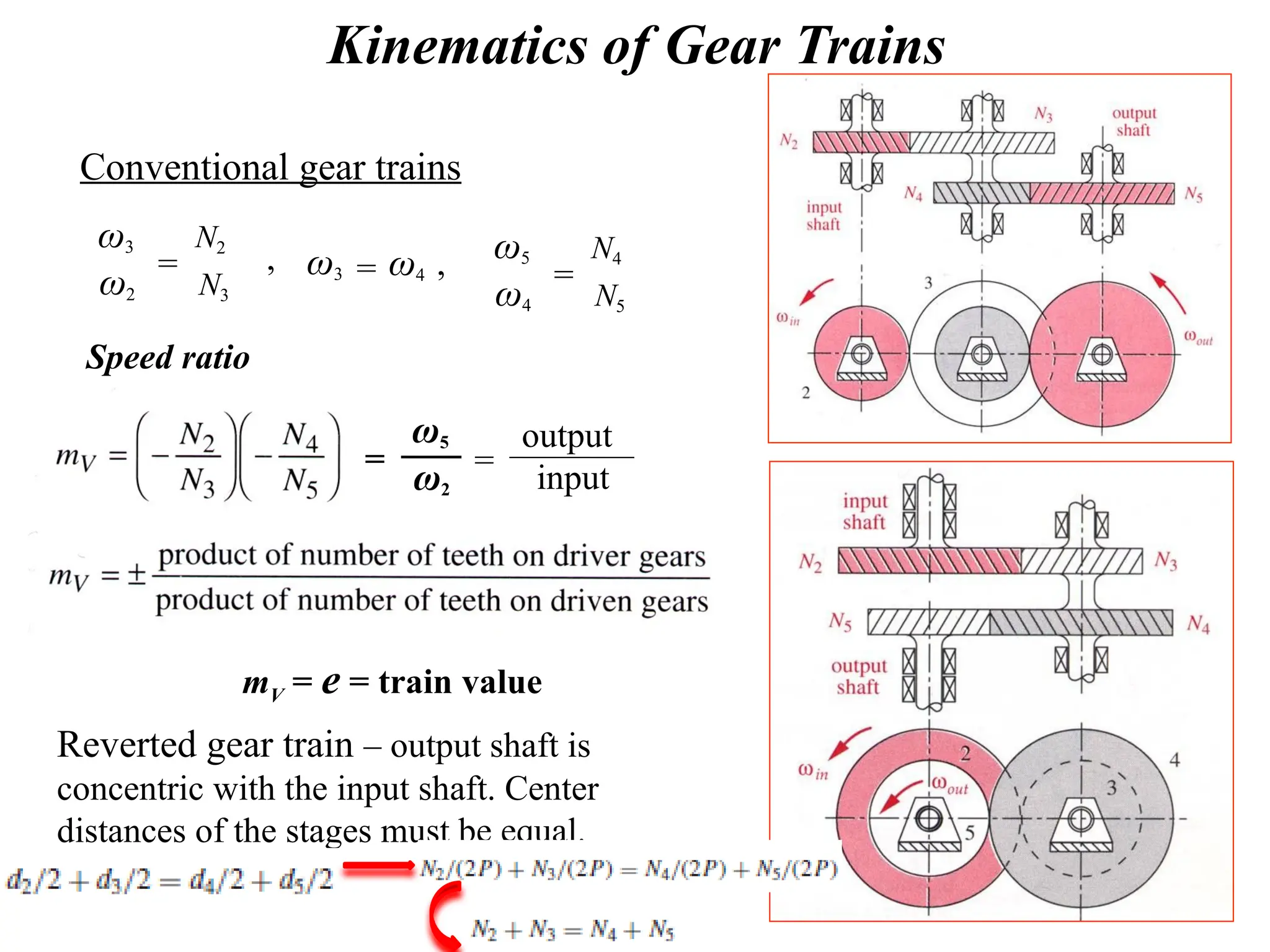

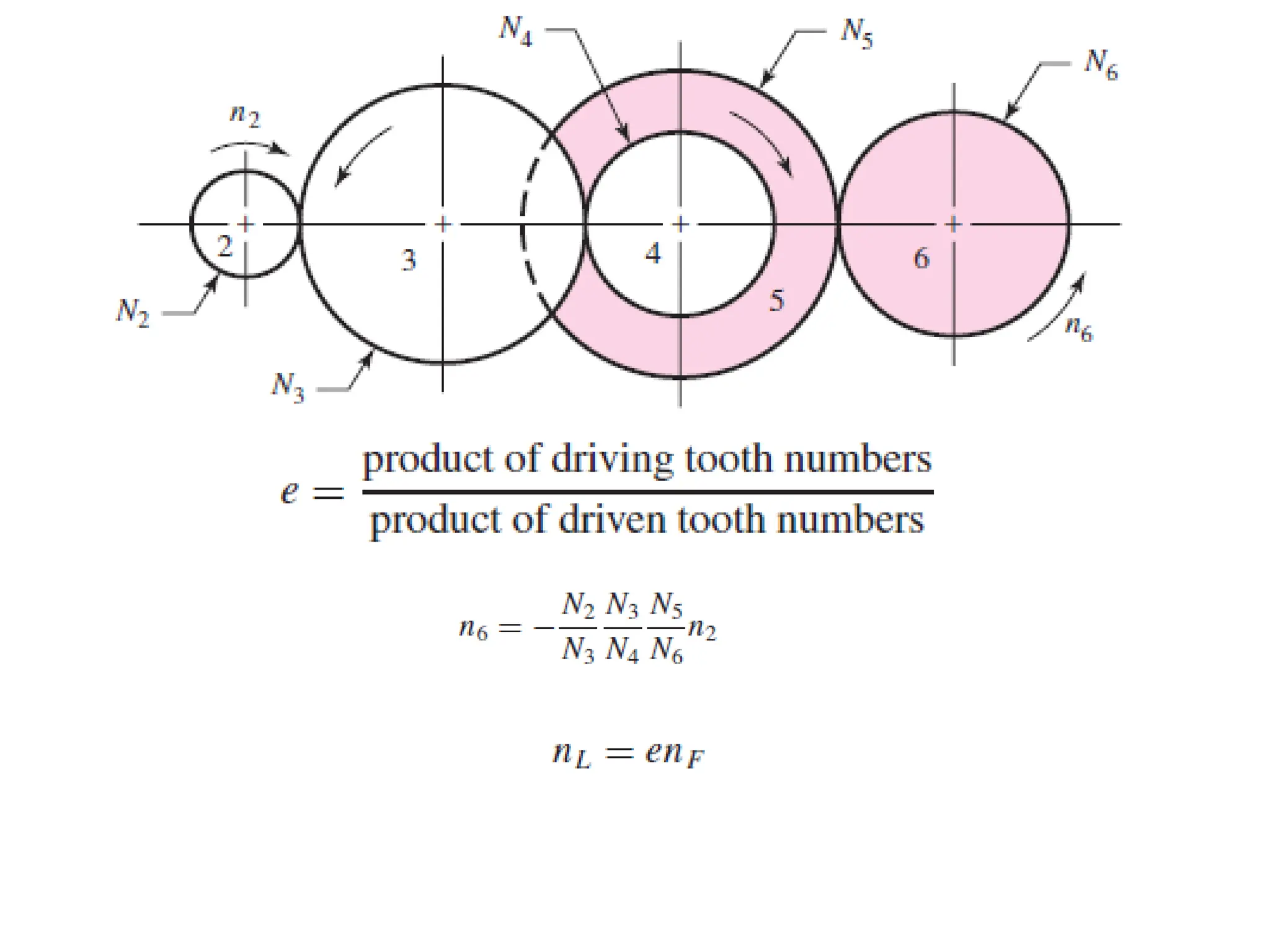

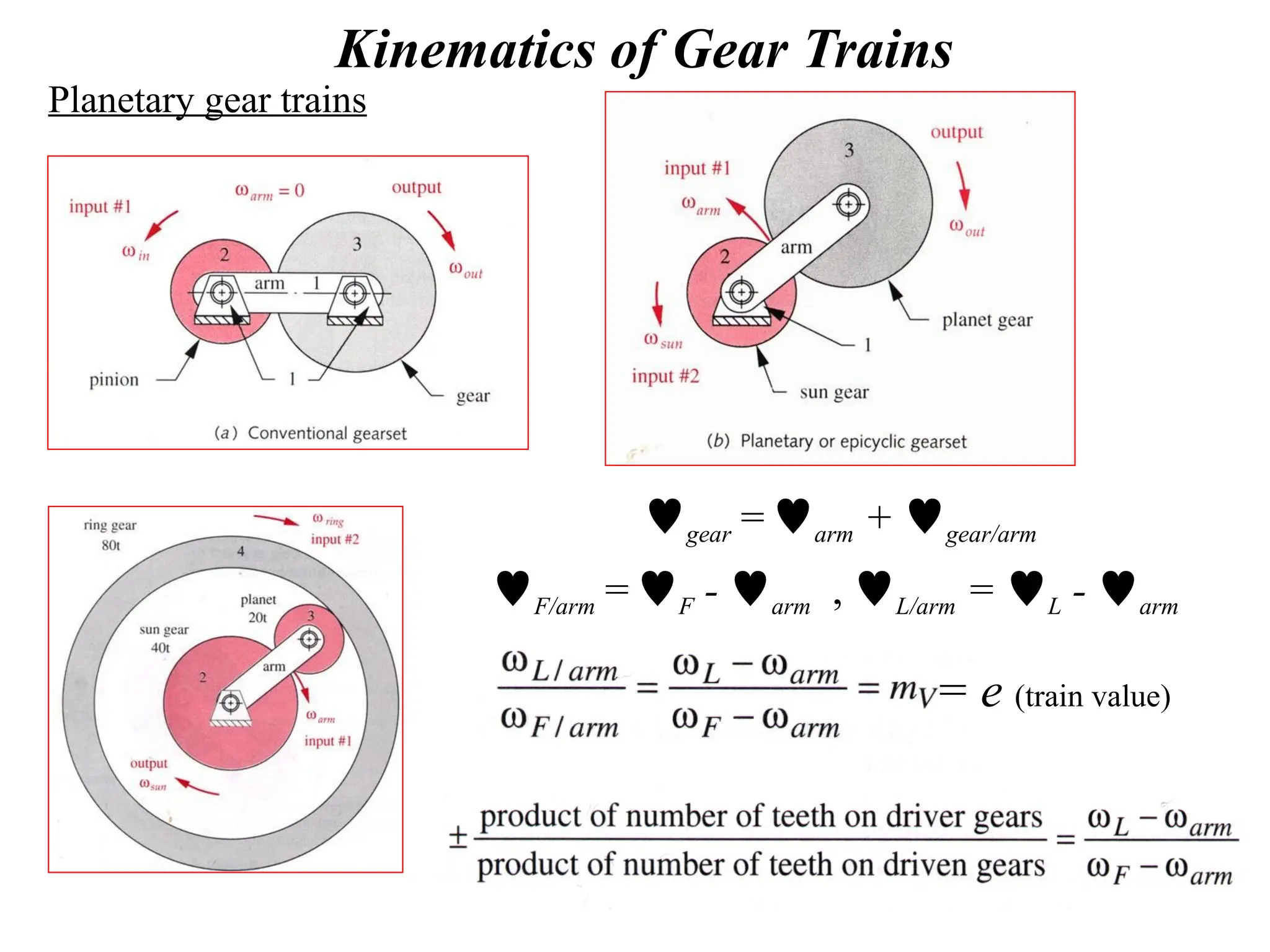

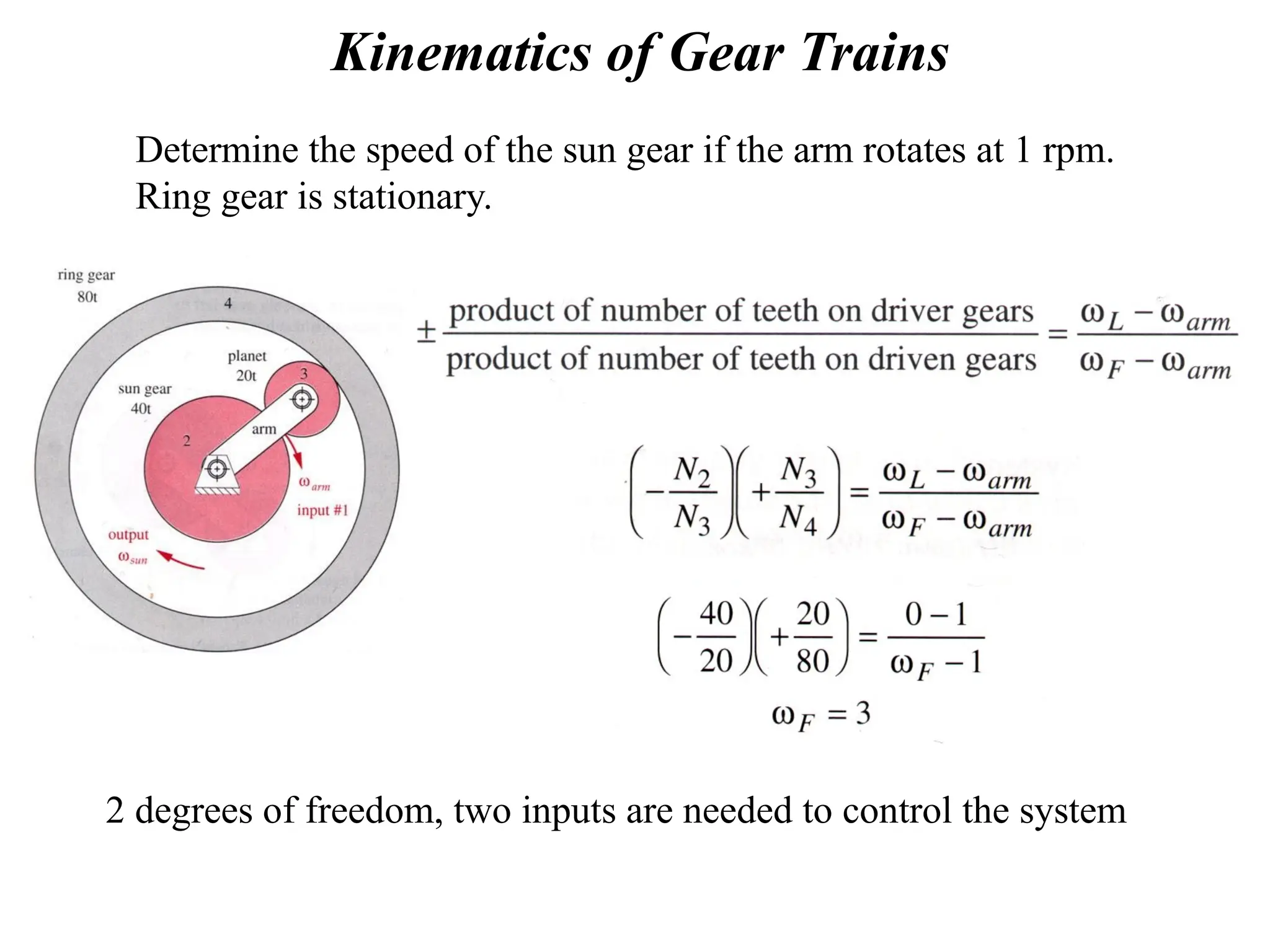

The document discusses the fundamentals of gears, their types, and their applications in transmissions to convert speed and torque. It covers the kinematics of gear trains, tooth specifications, contact ratios, and interference problems associated with gears. Additionally, it provides formulas for gear analysis and detailed descriptions of spur, helical, bevel, and worm gears.