This document provides an overview of gears, including their classification, types, terminology, and applications. It discusses the following:

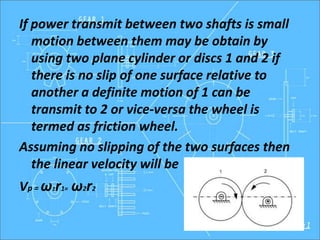

1. Gears are used to transmit motion between shafts through engaging teeth and can transfer motion through rolling or sliding contact.

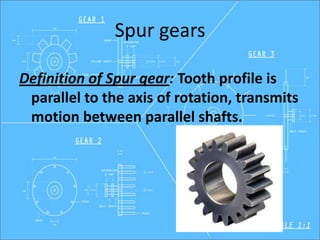

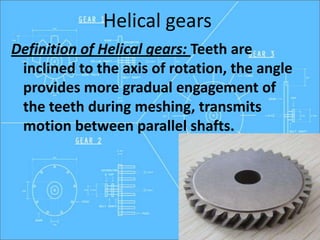

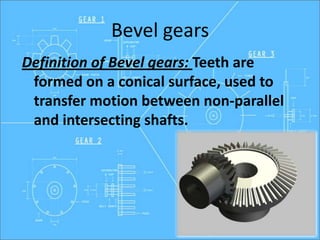

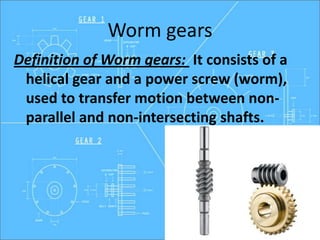

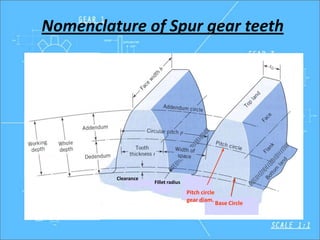

2. Gears are classified based on shaft positioning, peripheral velocity, gearing type, and tooth positioning. Common types include spur gears, helical gears, bevel gears, worm gears, and rack and pinion gears.

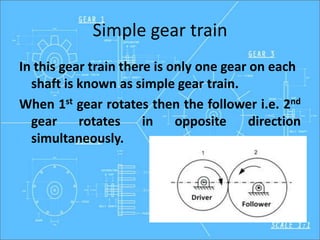

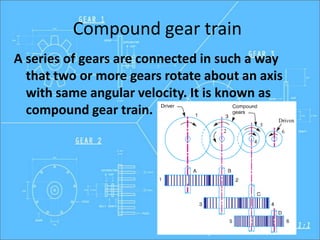

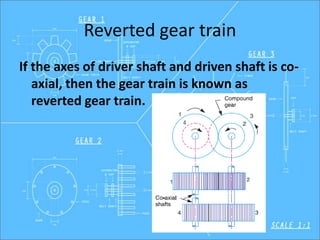

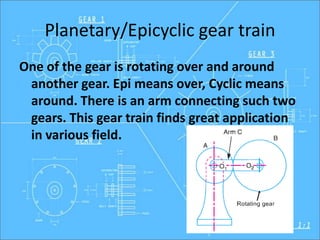

3. Gear trains such as simple, compound, reverted, and planetary arrangements are used to transmit motion from one shaft to another.

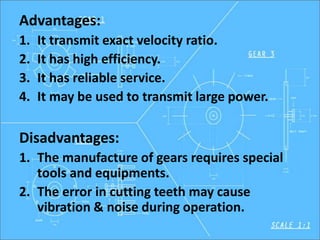

Gears are widely used to transmit motion in machinery due to advantages like transmitting exact