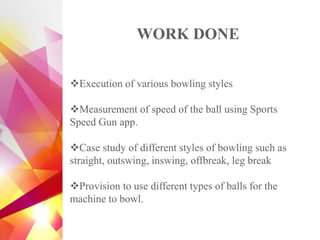

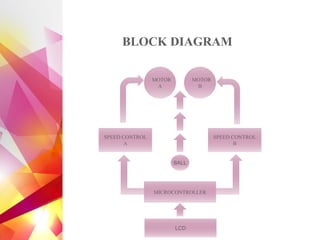

The document details the design and development of a cost-effective cricket bowling machine that accommodates various ball types and bowling styles. It includes specifications for components such as induction motors, wheels, and a microcontroller, along with features like speed control and an LCD display for monitoring. Future improvements aim to incorporate advanced bowling technologies and safety measures.

![COMPONENTS USED

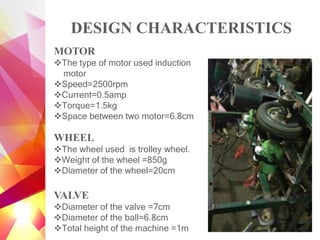

• Induction Motors

[2500rpm, 0.35HP,

0.5amp]

• Trolley Wheels

[diameter=21cm]

• Electronic Regulators

• Ball Bearing

• Antifriction Bearing

• Sleeve Bearing

• Flange Bolts

• Screws

• Metal Frame

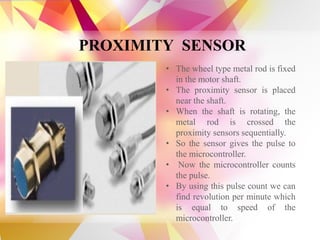

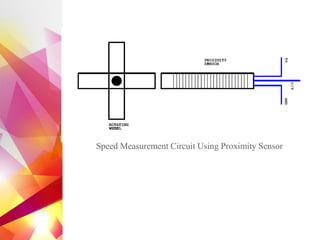

• Proximity Sensor

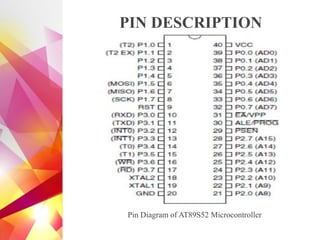

• AT89S52

Microcontroller

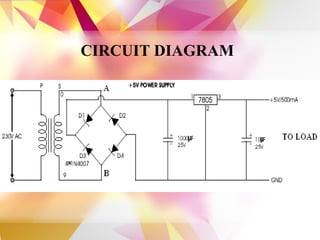

• IC 7805

• LED

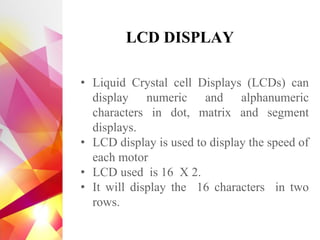

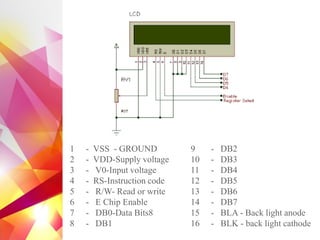

• LCD 16×2](https://image.slidesharecdn.com/apr2k16finalreviewppt-170906144934/85/Presentation-on-Cricket-Bowling-Machine-4-320.jpg)