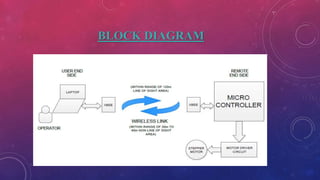

This document summarizes a project to control a stepper motor wirelessly using Zigbee technology. The project uses a microcontroller, Zigbee modules, and XCTU software to send commands from a laptop to rotate the stepper motor in either direction. The system allows remote control of mechanical devices like robotic arms up to 30 meters indoors. Future improvements could include integrating a tachometer sensor to detect if the motor actually rotated as commanded and adding password protection to the XCTU software.