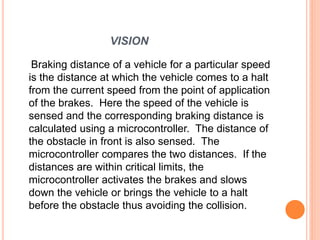

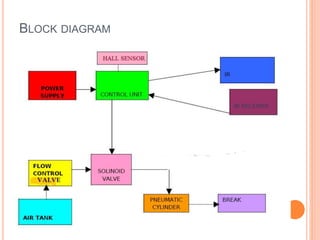

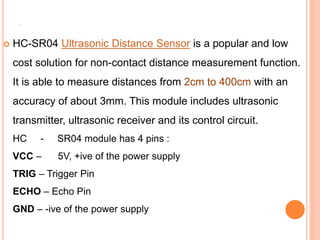

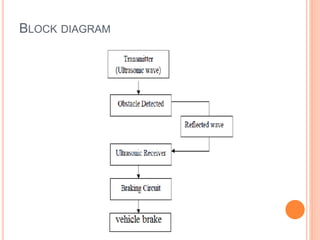

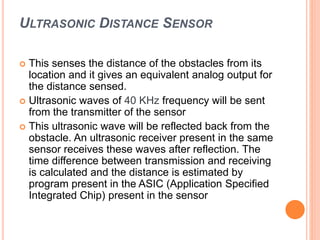

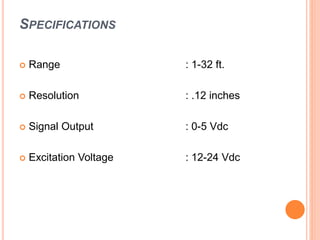

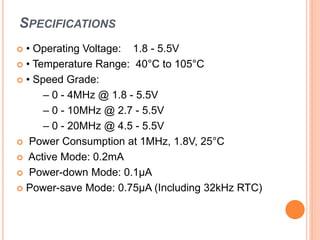

The document discusses the design of an intelligent braking system aimed at preventing vehicle accidents caused by driver errors and technical failures. It details the components used, including sensors, a microcontroller, and a pneumatic cylinder, and explains how the system calculates braking distance to automatically apply brakes when necessary. The implementation of this system could enhance safety in vehicles and may be made mandatory, similar to seat belt use.

![TEAM MEMBERS :

K JITHENDRA - 15695A0309 ME

C RAMA KRISHNA - 15695A0318 ME

R JASWANTH RAJU - 15695A0415 ECE

K LOKESH - 15695A0421 ECE

U MAHENDRA NAIDU - 15695A0422 ECE

GUIDES NAME :

Ms.CK.HEMANTHA LAKSHMI [ECE]

Mr. GUNA SEKHAR [ME]](https://image.slidesharecdn.com/intelligentbrakingsystem-191124031026/85/Intelligent-braking-system-2-320.jpg)