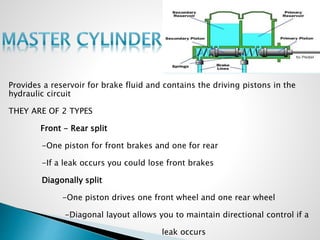

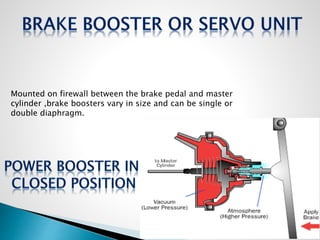

Abhishek Kumar's document discusses the principles and components of hydraulic braking systems. It explains that hydraulics uses pressurized fluids to create force and motion. The key principles are that fluids cannot be compressed and can transmit both movement and increased force via pressure. The document then describes the major components of hydraulic braking systems including the master cylinder, brake lines, brake calipers or drums, brake boosters, and proportioning valves. It explains how these components work together using hydraulic principles to stop a vehicle safely and efficiently.