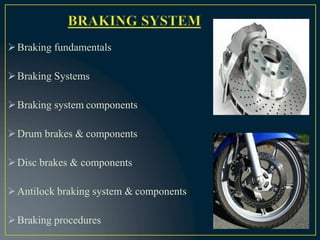

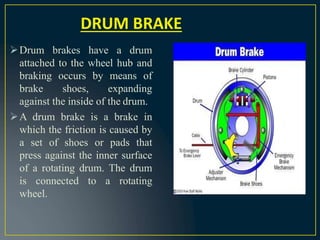

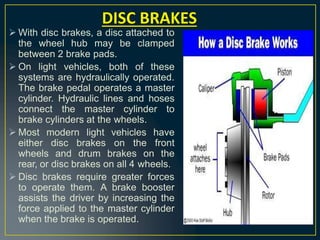

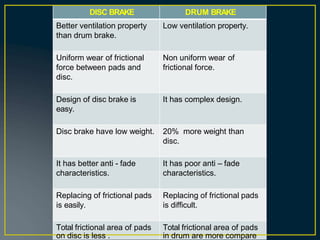

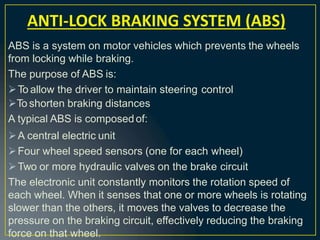

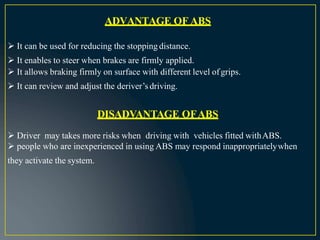

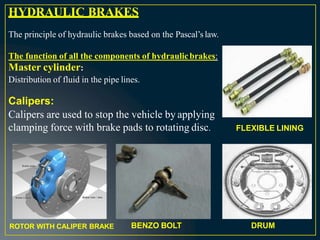

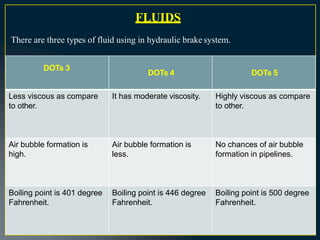

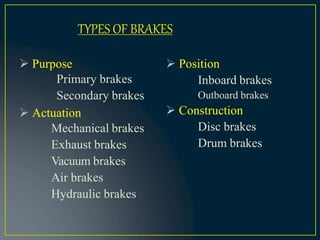

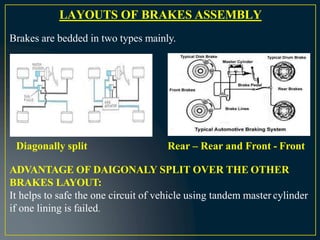

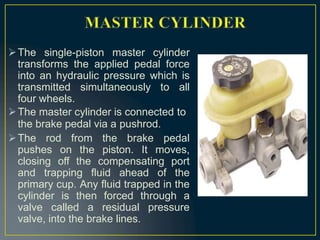

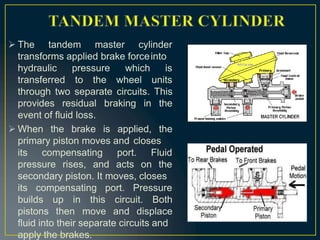

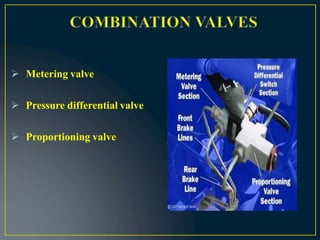

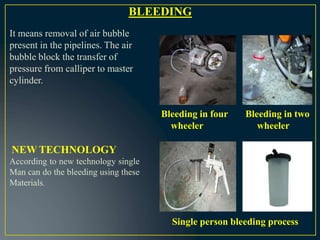

The document discusses various types of braking systems, focusing on the principles and components involved in drum and disc brakes, along with hydraulic brakes. It also highlights the operation of the Anti-lock Braking System (ABS), its advantages and disadvantages, and details about the hydraulic components including the master cylinder and the braking process. Additionally, it covers parking brake systems and introduces concepts such as weight transfer, brake fade, and the importance of proper maintenance like bleeding air from pipelines.