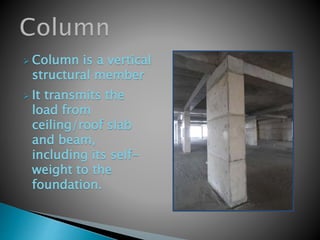

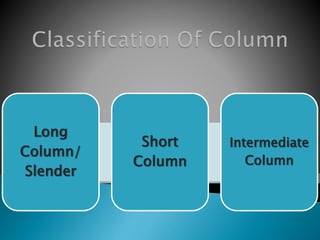

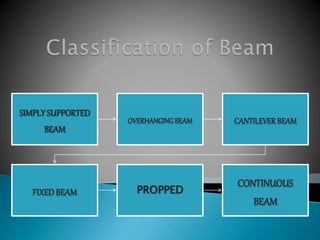

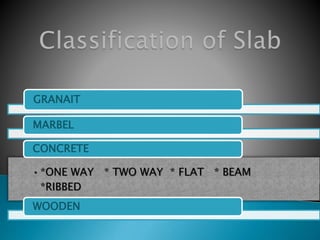

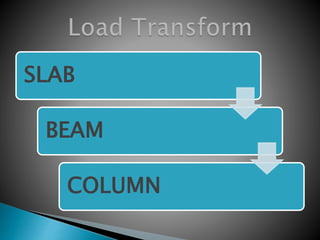

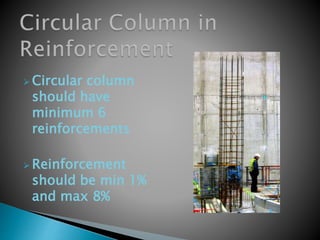

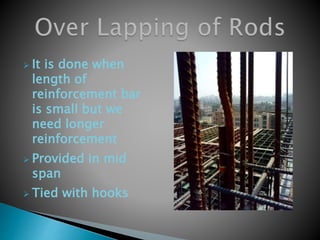

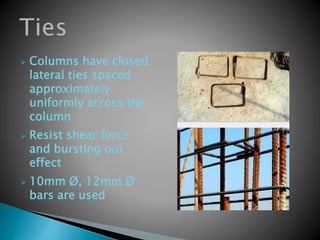

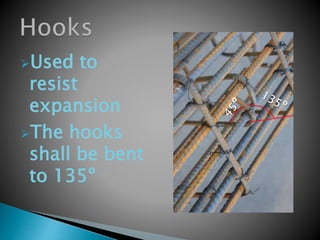

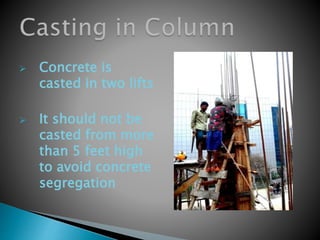

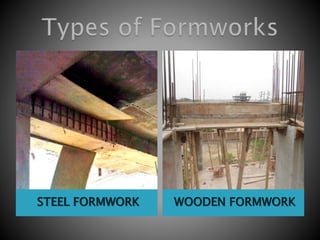

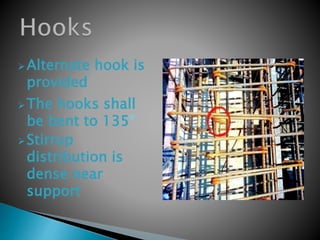

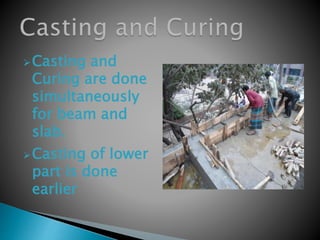

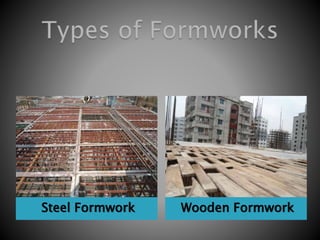

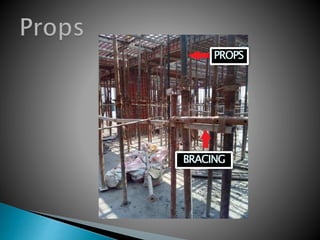

This document summarizes a presentation on beams, slabs, and columns. It lists the group members presenting and defines beams, slabs, and columns. It describes different types of beams, slabs, reinforcement details, formwork types, construction process including casting, compaction and curing. Construction examples are provided and materials used are outlined.