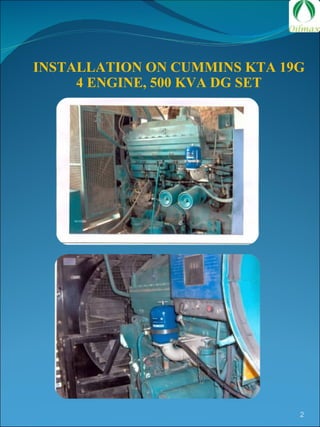

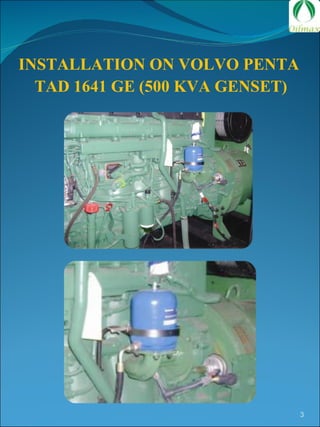

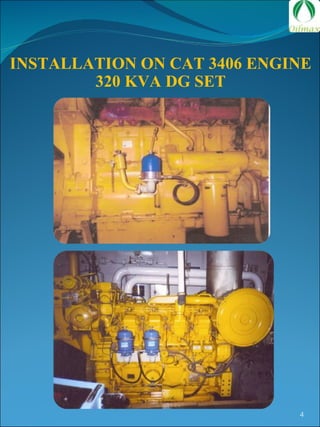

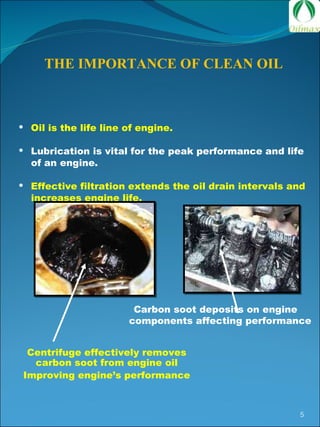

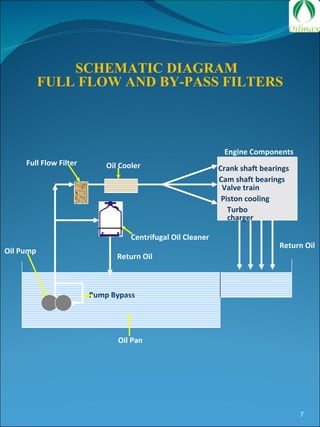

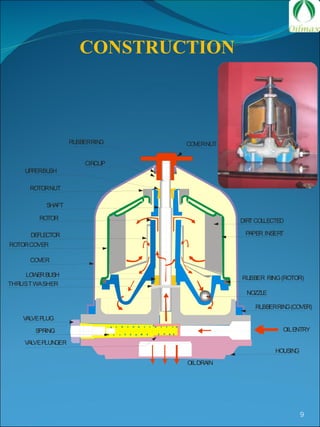

The document outlines the installation and benefits of centrifugal oil cleaners for diesel engines, highlighting their importance in maintaining oil cleanliness and extending engine life. It explains the limitations of full-flow filters in removing fine particles and how centrifuges utilize centrifugal force to effectively separate carbon soot and other contaminants from oil. Additionally, it provides specifications for various centrifugal models suited for different engine oil sump capacities.